Humidity Sensors: Best Guide on Types & Applications

Have you ever noticed that after rain, the air feels a bit damp? It’s like the water is hanging in the air. But guess what? In some air conditioners, you just press a few buttons, and suddenly the whole atmosphere brightens up. Ever wondered how and why that happens?

Well, it turns out that moisture accumulates in the air, creating humidity. Luckily, your AC has a humidity sensor that detects and cleans up the humidity for you. Isn’t that amazing? Let’s dive into how this magical process works.

Read More About

So, this humidity sensor, also known as a hygrometer, does the job of sensing, measuring, and reporting both moisture and air temperature. The ratio of moisture in the air to the highest amount of moisture at a specific air temperature is what we call relative humidity. And believe it or not, relative humidity is crucial for your comfort.

Humidity sensors, also known as hygrometers, are devices designed to measure and monitor the amount of moisture or water vapor in the air. These sensors find applications in various fields, including meteorology, industrial processes, HVAC (Heating, Ventilation, and Air Conditioning) systems, agriculture, and consumer electronics. They play a crucial role in maintaining optimal conditions in environments where humidity levels need to be controlled.

These sensors operate by detecting changes that affect electrical currents or temperature in the air.

Parameters for Judging Humidity Sensor Performance:

Accuracy: Each sensor has its calibration curve, weighing pros and cons based on a 9-point system.

Linearity: It indicates the voltage deviation from the BFSL value and the measured output voltage value, converted to relative humidity.

Reliability: Sensors may fall out of sync during measurements, but for a sensor to be useful, it must provide reliable measurements.

Repeatability: Measurements should not drift apart; repeatability is the measurement of drift among measurements of a single quantity.

Response Time: The time taken for a sensor to rise to 66% (rise time) or fall to 33% (fall time) of the maximum output voltage is known as the response time.

Tips on How Humidity Sensors Work:

Coulometric: An electrolyte is formed by water absorption, resulting in a current level proportional to the moisture content.

Gravimetric: A drying agent exposed to moist air gains weight, corresponding to the moisture amount.

Microwave/Infrared: The transmitted signal varies with increasing humidity, and attenuation indicates the moisture content.

Types of Humidity Sensors:

Capacitive Humidity Sensors:

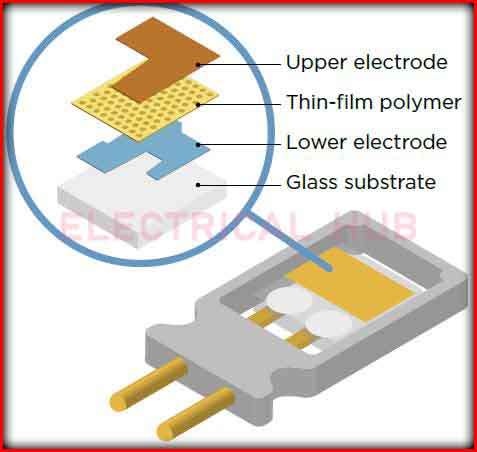

Capacitive humidity sensors are a type of sensor that relies on changes in capacitance to measure the amount of moisture in the air. These sensors are widely used in various applications due to their high accuracy, quick response time, and good long-term stability. Here’s a more detailed explanation of how capacitive sensors work and their key features:

Working Principle of Capacitive Humidity Sensors:

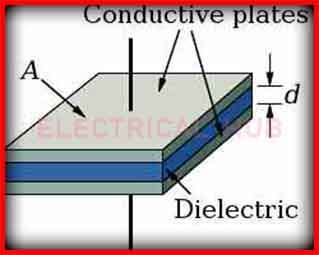

Capacitance Change: The core principle involves the variation in the capacitance of a sensing element based on the water vapor content in the surrounding air. A typical capacitive humidity sensor consists of a thin polymer film that absorbs or desorbs water molecules based on the humidity level.

Dielectric Constant: The dielectric constant of the polymer film changes with the absorption or release of water molecules. This alteration affects the capacitance of the sensor.

Capacitance Measurement: The sensor is part of a capacitive circuit, and changes in capacitance are measured and converted into a humidity reading.

Key Features of Capacitive Humidity Sensors:

Accuracy: Capacitive sensors offer high accuracy in measuring humidity levels, making them suitable for applications where precise humidity control is essential.

Response Time: These sensors provide a quick response to changes in humidity, making them effective in dynamic environments that require rapid adjustments.

Long-Term Stability: Capacitive sensors generally exhibit good long-term stability, ensuring reliable and consistent performance over extended periods.

Low Hysteresis: Hysteresis refers to the difference in readings during the absorption and desorption of moisture. Capacitive sensors often have low hysteresis, contributing to their reliability.

Low Power Consumption: Many capacitive humidity sensors operate with low power consumption, making them suitable for battery-powered devices and applications where energy efficiency is crucial.

Applications of Capacitive Humidity Sensors:

HVAC Systems: These humidity sensors are widely used in heating, ventilation, and air conditioning systems to maintain optimal indoor air quality.

Consumer Electronics: Found in devices like hygrometers, dehumidifiers, and air purifiers for home use.

Industrial Processes: Used in various manufacturing processes where precise humidity control is required for product quality and consistency.

Meteorology: Deployed in weather stations and environmental monitoring systems for accurate humidity measurements.

Medical Devices: Utilized in certain medical devices and applications where controlling humidity is critical, such as incubators and respiratory equipment.

Resistive Humidity Sensors (Hygroscopic Polymer Sensors):

Resistive humidity sensors, also known as hygroscopic polymer sensors, operate on the principle that certain materials experience changes in electrical resistance in response to variations in humidity levels.

These sensors are widely used in a range of applications due to their simplicity, low cost, and suitability for various environments. Here’s a detailed explanation of how resistive humidity sensors work, their key features, and applications:

Working Principle of Resistive Humidity Sensors

Hygroscopic Material: These sensors consist of a hygroscopic material, often a polymer or ceramic, which absorbs or releases water molecules based on the surrounding humidity.

Conductivity Change: The electrical conductivity of the hygroscopic material changes as it absorbs or desorbs moisture. This change in conductivity is directly proportional to the humidity level.

Resistance Measurement: The resistance of the sensor is measured, and this value is then correlated with the humidity level. Typically, higher humidity leads to a decrease in resistance, and lower humidity results in increased resistance.

Key Features of Resistive Humidity Sensors

Simplicity: Resistive sensors are relatively simple in design, making them cost-effective and easy to manufacture.

Low Cost: These sensors are generally less expensive compared to some other types of humidity sensors, making them suitable for applications where cost is a significant factor.

Suitability for Various Environments: Resistive sensors are robust and can operate in a wide range of environmental conditions, including moderate temperature and humidity variations.

Linearity: Many resistive humidity sensors exhibit a linear response to changes in humidity levels, simplifying calibration and data interpretation.

Applications of Resistive Humidity Sensors

Weather Stations: Resistive sensors are used in weather stations to measure and monitor atmospheric humidity levels.

Home Appliances: Found in household devices such as hygrometers, dehumidifiers, and some types of air purifiers.

Industrial Processes: Applied in various industrial processes where humidity control is critical, such as in the production of pharmaceuticals or food.

Automotive Applications: Used in automotive climate control systems to measure cabin humidity and optimize air conditioning.

Consumer Electronics: Integrated into gadgets like handheld weather meters or electronic devices with humidity monitoring capabilities.

Considerations of Resistive Humidity Sensors

Response Time: Resistive humidity sensors generally have a moderate response time compared to some other sensor types. This factor should be considered in applications where rapid response is crucial.

Hysteresis: Similar to other humidity sensors, resistive sensors may exhibit hysteresis, which is the difference in readings during the absorption and desorption of moisture.

Thermal Hygrometers:

Thermal hygrometers, also known as psychrometers or wet-and-dry bulb hygrometers, are devices designed to measure humidity based on the principles of heat transfer and the cooling effect of water evaporation.

These hygrometers are commonly used in applications where the measurement of both temperature and humidity is essential. Here’s a detailed explanation of how thermal hygrometers work, their key features, and their applications:

Working Principle of Thermal Hygrometers

Dry-Bulb Temperature: The dry-bulb temperature is the ambient air temperature measured using a regular thermometer.

Wet-Bulb Temperature: The wet-bulb temperature is measured using a thermometer covered with a wet cloth or wick. The moisture on the cloth evaporates, causing a cooling effect.

Evaporative Cooling: The wet-bulb temperature is lower than the dry-bulb temperature due to the cooling effect of water evaporation. The greater the difference between the two temperatures, the lower the humidity.

Psychrometric Chart: Using a psychrometric chart or calculations based on psychrometric principles, the humidity level can be determined by comparing the dry-bulb and wet-bulb temperatures.

Key Features of Thermal Hygrometers

Simple Design: Thermal hygrometers have a relatively simple design, making them easy to use and maintain.

Low Cost: Compared to some advanced humidity sensors, thermal hygrometers are often more affordable.

Suitability for High-Temperature Environments: Thermal hygrometers can be effective in high-temperature environments where other types of sensors might be less practical.

No External Power Required: Unlike some electronic humidity sensors, thermal hygrometers do not require external power sources, making them suitable for remote or unpowered locations.

Applications of Thermal Hygrometers

HVAC Systems: Used for assessing indoor air quality and optimizing heating, ventilation, and air conditioning (HVAC) systems.

Agriculture: Applied in agriculture to monitor environmental conditions in greenhouses and assess plant health.

Meteorology: Utilized in weather stations for humidity measurements, often in combination with other sensors.

Industrial Processes: Employed in certain manufacturing processes where temperature and humidity control are critical.

Drying Processes: Used in industries such as food processing or textiles to monitor and control drying processes.

Considerations of Thermal Hygrometers

Response Time: Thermal hygrometers may have a slower response time compared to some electronic sensors, and this should be considered in applications requiring rapid humidity measurements.

Accuracy: The accuracy of thermal hygrometers can be influenced by factors such as air circulation, ambient temperature, and the condition of the wet cloth. Regular calibration may be necessary.

Gravimetric Humidity Sensors:

Gravimetric humidity sensors, also known as gravimetric hygrometers, are a type of humidity sensor that measures the moisture content in the air based on the change in mass of a material as it absorbs or desorbs water vapor.

These sensors are characterized by their high accuracy and precision, making them suitable for laboratory and scientific applications where precise humidity measurements are essential. Here’s a detailed explanation of how gravimetric humidity sensors work, their key features, and their applications:

Working Principle of Gravimetric Humidity Sensors

Hygroscopic Material: Gravimetric humidity sensors use a hygroscopic material, often a special type of salt, which has the ability to absorb or desorb water vapor based on the humidity of the surrounding air.

Weight Change: As the hygroscopic material absorbs water, its mass increases. Conversely, when it releases water vapor, its mass decreases.

Balanced Equilibrium: The system reaches an equilibrium state when the rate of water vapor absorption equals the rate of release, and the change in mass becomes proportional to the humidity level.

Measurement and Calibration: The change in mass is measured using a highly sensitive balance. Gravimetric humidity sensors are often calibrated against known humidity levels to ensure accurate readings.

Key Features of Gravimetric Humidity Sensors

High Accuracy: Gravimetric humidity sensors are known for their high accuracy, making them a reference standard for humidity measurements in laboratory settings.

Low Hysteresis: These sensors typically exhibit low hysteresis, ensuring that the readings remain consistent during both absorption and desorption of water vapor.

Wide Operating Range: Gravimetric humidity sensors can operate over a wide range of humidity levels, making them versatile for various applications.

Traceability: Because gravimetric measurements are directly linked to fundamental physical properties, these sensors provide a traceable and reliable reference for humidity calibration.

Applications of Gravimetric Humidity Sensors

Calibration Standards: Gravimetric humidity sensors are often used as primary standards for calibrating other types of humidity sensors due to their high accuracy and traceability.

Scientific Research: Commonly employed in research laboratories, particularly in fields such as material science, chemistry, and environmental science, where precise humidity control is critical.

Quality Control: Used in industries where maintaining specific humidity levels is crucial for product quality, such as pharmaceuticals and semiconductor manufacturing.

Considerations of Gravimetric Humidity Sensors

Complexity and Cost: Gravimetric humidity sensors are generally more complex and expensive compared to some other types of humidity sensors. They are primarily used in applications that require the highest levels of accuracy.

Response Time: These sensors may have a slower response time compared to some electronic sensors, which could limit their use in applications requiring rapid humidity measurements.

Applications of Humidity Sensors

These sensors have a broad range of applications that impact our daily lives. Here’s a glimpse into where and how these sensors are put to use:

Health and Comfort:

Individuals with health conditions affected by humidity, such as respiratory issues, benefit from humidity sensors that help monitor and control indoor moisture levels for comfort.

Home Environment:

Humidity sensors are commonly integrated into heating, ventilating, and air conditioning (HVAC) systems in homes. They regulate the indoor climate to ensure optimal comfort and prevent issues like mold growth.

Industrial Spaces:

In industrial settings, humidity sensors are essential for maintaining specific environmental conditions. Industries, such as pharmaceuticals and electronics manufacturing, rely on precise humidity control to ensure product quality.

Museums and Archives:

Museums and archival facilities use humidity sensors to protect valuable artifacts and documents. Maintaining stable humidity levels helps preserve these items by preventing deterioration.

Automobiles:

In cars, humidity sensors contribute to passenger comfort. They are often integrated into climate control systems to regulate the interior atmosphere and prevent window fogging.

Greenhouses and Agriculture:

These sensors play a vital role in greenhouse environments and agriculture. They help optimize conditions for plant growth, ensuring that crops receive the right amount of moisture.

Meteorology Stations:

Meteorology stations utilize humidity sensors to measure and report atmospheric humidity levels. This data is crucial for weather forecasting and understanding climatic patterns.

Data Centers:

Humidity control is critical in data centers to prevent equipment malfunctions. Humidity sensors assist in maintaining the ideal environmental conditions for sensitive electronic components.

Food Storage and Processing:

In the food industry, humidity sensors are used for proper storage and processing conditions. Maintaining the right humidity levels helps extend the shelf life of food products.

HVAC Energy Efficiency:

Humidity sensors contribute to the energy efficiency of HVAC systems by optimizing moisture levels. This not only enhances comfort but also reduces energy consumption.

Weather Stations and Instruments:

Weather instruments, such as hygrometers, employ humidity sensors to measure and record atmospheric moisture. This data is valuable for various scientific and research purposes.

Consumer Electronics:

Some consumer electronics, like certain wearable devices and gadgets, may incorporate humidity sensors to enhance performance or provide information to users.

Humidity sensors, with their diverse applications, play a crucial role in maintaining comfort, preserving assets, and ensuring optimal conditions across various industries and environments.

What is a humidity sensor?

A humidity sensor, also known as a hygrometer, is a device that measures and reports the moisture content in the air. It is used to determine humidity levels, which can be crucial for various applications, including climate control and environmental monitoring.

How do humidity sensors work?

These sensors work by detecting changes in electrical currents or temperature in the air. There are different types of humidity sensors, such as capacitive, resistive, and thermal, each employing unique mechanisms to measure relative humidity.

What is relative humidity?

Relative humidity is the ratio of the amount of moisture in the air to the highest amount of moisture the air can hold at a specific temperature. It is expressed as a percentage and is a key factor in assessing comfort and environmental conditions.

What are the types of humidity sensors?

There are three basic types of humidity sensors: capacitive, resistive, and thermal. Capacitive sensors measure humidity using a metal oxide strip, resistive sensors use ions in salts to measure impedance, and thermal sensors use temperature-based conductivity.

Where are humidity sensors commonly used?

These sensors have a wide range of applications, including in homes (HVAC systems), industrial spaces, automobiles, museums, greenhouses, meteorology stations, data centers, and various consumer electronics.

Why is humidity control important in certain industries?

Industries such as pharmaceuticals and electronics manufacturing require precise humidity control to maintain product quality. Improper humidity levels can lead to issues like condensation, mold growth, and damage to sensitive equipment.

How do humidity sensors contribute to energy efficiency in HVAC systems?

These sensors in HVAC systems optimize moisture levels, preventing excessive use of energy. By regulating humidity, these sensors enhance comfort and reduce the load on cooling systems, leading to improved energy efficiency.

Can humidity sensors be used in weather forecasting?

Yes, humidity sensors play a crucial role in meteorology stations for measuring atmospheric humidity. This data is essential for weather forecasting and understanding climatic patterns.

What are some common parameters used to judge the performance of humidity sensors?

Common parameters include accuracy, linearity, reliability, repeatability, and response time. These factors help assess how well a sensor performs in various conditions.

Are there different methods for measuring humidity with sensors?

Yes, humidity sensors use various methods, including coulometric (electrolyte absorption), gravimetric (weight gain by a drying agent), and microwave/infrared (signal variation with humidity).

Can humidity sensors be used in agricultural settings? A11

Yes, These sensors are used in agriculture, particularly in greenhouses, to optimize environmental conditions for plant growth. They help ensure crops receive the appropriate moisture levels.

How do humidity sensors contribute to the preservation of artifacts in museums?

These sensors in museums help maintain stable humidity levels, preventing artifacts from deteriorating due to excessive moisture. This preservation measure is crucial for protecting valuable items.

Are humidity sensors commonly found in consumer electronics?

Yes, some consumer electronics, such as wearables and gadgets, may incorporate humidity sensors. These sensors can enhance device performance or provide users with information related to environmental conditions.

How do humidity sensors contribute to health and comfort in homes?

These sensors in HVAC systems at homes regulate indoor moisture levels, providing a comfortable living environment. This is especially beneficial for individuals with health conditions influenced by humidity, such as respiratory issues.

Can humidity sensors be calibrated for accuracy?

Yes, humidity sensors can be calibrated to ensure accuracy. Calibration helps align the sensor’s readings with a known reference, improving the reliability of the data provided. Regular calibration is recommended for consistent performance.

Worth Read Posts

Subscribe to our Newsletter “Electrical Insights Daily” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.