IEC 60079 Guide: Everything You Need to Know

IEC 60079 is a sequence of global standards developed with the aid of the International Electrotechnical Commission (IEC) that addresses the device utilized in explosive atmospheres, wherein there may be a chance of hearth or explosion due to the presence of flammable gases, vapors, or flamable dusts.

This series of requirements is regularly called the IEC 60079 series; and is essential for ensuring safety in environments in which explosive atmospheres may be encountered.

Read More About

What is the IEC 60079 code?

The IEC 60079 code refers to a series of global standards evolved with the aid of the International Electrotechnical Commission (IEC) that specifically deal with equipment utilized in explosive atmospheres.

The full collection is referred to as IEC 60079 and includes numerous elements, each that specializes in distinctive aspects of electrical and non-electric device meant to be used in environments where there’s a hazard of fireplace or explosion due to the presence of flammable gases, vapors, or flamable dusts.

The IEC 60079 collection covers a wide variety of subjects related to dangerous areas, consisting of gadget class, design, creation, testing, installation, inspection, and upkeep.

It gives recommendations and necessities to make certain the safe operation of system in those potentially risky environments.

Where to Buy IEC 60079 Books

[wptb id=11165]Aspects of IEC 60079

The IEC 60079 series covers various aspects associated with electric and non-electric equipment utilized in risky regions, inclusive of:

Classification of Hazardous Areas: This part of the series defines and categorizes unsafe regions into zones based totally at the probability and period of the presence of explosive atmospheres. It enables determining the level of protection required for equipment.

Equipment Protection Levels: The collection specifies exclusive stages of safety (e.G., Ex d for flameproof enclosures, Ex e for elevated protection) that device should meet to operate thoroughly in risky regions.

Construction and Testing of Equipment: The requirements offer necessities for the layout, creation, and testing of electrical and non-electric device to make certain it is secure to be used in explosive atmospheres.

Installation, Inspection, and Maintenance: These components of the collection cover the set up and upkeep of gadget in hazardous areas, such as recommendations for inspections and periodic checks.

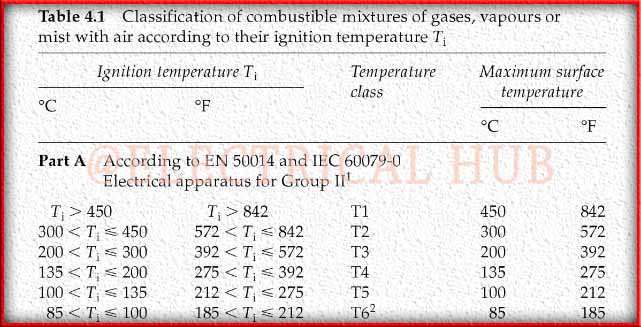

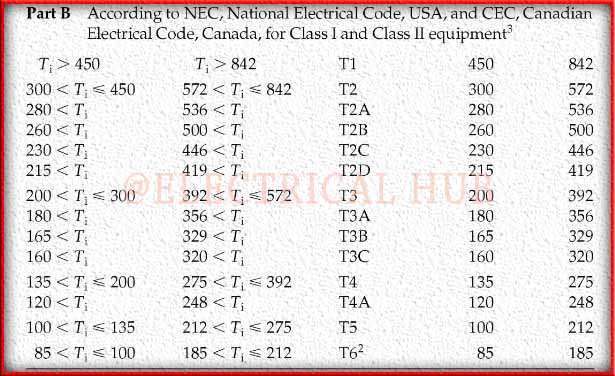

Gas Group and Temperature Classification: These requirements classify hazardous gases and dusts into agencies primarily based on their ignition traits, and in addition they provide temperature classification to specify the most surface temperature of system.

Intrinsically Safe Equipment: This part makes a speciality of the layout and use of intrinsically safe electrical circuits and device which can be incapable of causing ignition within the presence of explosive atmospheres.

Documentation and Marking: The collection specifies necessities for gadget labeling, marking, and documentation to make certain clear identification and traceability. The IEC 60079 collection is vital for industries and programs where the risk of explosion or fireplace is a situation, including oil and fuel, chemical, pharmaceutical, mining, and production.

Critical Parameters in IEC 60079

In the context of safety standards for equipment used in potentially explosive atmospheres, several critical parameters are considered:

Ignition Temperatures (T): These temperatures range from approximately -100°C to 650°C. Ignition temperatures are vital because they specify the temperature at which a substance can ignite when exposed to a potential ignition source. This information is essential for the safety of equipment and components in combustible atmospheres.

MESG (Maximum Experimental Safe Gap) Values: These values range from 0.3 mm to 3.2 mm . MESG values help distinguish between areas where flames can transmit through gaps and areas where they cannot. They are particularly relevant to flameproof enclosures and guide the design of joints (such as those for shafts, doors, or covers) to prevent the internal propagation of combustible atmospheres to the external environment.

Minimum Ignition Energy Values: These values range from approximately 10 μJ to some 102 μJ. Minimum ignition energy values pertain to a specific type of protection known as “intrinsic safety.” This protection method limits electrical circuit currents and voltages, as well as energy releases, to levels that are insufficient to ignite a combustible mixture. It is crucial for minimizing the risk of ignition.

In practical terms, combustible mixtures are categorized into temperature classes based on their ignition temperatures and explosion groups determined by their MESG values. Notably, the maximum surface temperature of apparatus or components aligns with the lower limit of the ignition temperature range.

For example, an apparatus labeled as T3 with a maximum surface temperature of 200°C is suitable for use with combustible mixtures with ignition temperatures exceeding 200°C, providing a margin of safety.

It is important to highlight that the determination of ignition temperature, as per IEC 60079-4 standards, includes specific conditions such as surface shape and area. Additionally, specific considerations exist for Group I equipment used in coal mines, which are not subjected to temperature classification due to the presence of firedamp and/or coal dust.

The maximum surface temperature is limited to 150°C when there is a risk of coal dust deposits with a low glow temperature. In cases where such deposits are unlikely, the surface temperature limit is set at 450°C.

Finally, lower temperature classes are not established due to the exceptionally low ignition temperature of carbon disulfide (CS2), and temperature class limitations are in place for Class III equipment, primarily designed for ignitable fibers and flyings, according to the NEC (National Electrical Code, USA).

These classifications and parameters are essential for ensuring the safe operation of equipment in environments where the risk of fire or explosion is a concern. They help reduce the potential for ignition and protect against hazardous conditions.

What are the IEC 60079 groups?

The IEC 60079 collection of requirements defines corporations and classes for hazardous areas where explosive atmospheres may be present. These companies and classes are used to categorise one of a kind types of gases, vapors, and dusts based on their ignition traits. Here are the IEC 60079 businesses:

Gas Groups (Group I):

Group I consists of gases, vapors, and mists. These substances are divided into 3 subgroups based on their ignition characteristics:

- Group IIA: Atmospheres containing propane, hydrogen, and other gases with comparable traits.

- Group IIB: Atmospheres containing ethylene, fuel, acetone, and other gases with comparable traits.

- Group IIC: Atmospheres containing hydrogen, acetylene, and other gases with similar characteristics.

Dust Groups (Group II):

Group II includes flamable dusts. These dusts are labeled into three subgroups primarily based on their ignition traits:

- Group IIIC: Conductive dusts with the highest ignition power.

- Group IIIB: Conductive dusts with intermediate ignition strength.

- Group IIIA: Non-conductive dusts with the bottom ignition energy.

The IEC 60079 popular additionally defines gadget categories, which offer facts approximately the level of protection required for electric and non-electric equipment utilized in those unsafe regions. These classes are regularly denoted as "classes" inside the standard. The categories and their associated protection tiers are special as follows:

- Category 1 (Zone zero or Zone 20): Equipment for use in the presence of an explosive environment this is constantly present or present for long intervals.

- Category 2 (Zone 1 or Zone 21): Equipment to be used in the presence of an explosive atmosphere this is in all likelihood to occur at some point of ordinary operation.

- Category 3 (Zone 2 or Zone 22): Equipment for use inside the presence of an explosive surroundings that is not likely to arise throughout normal operation and, if it does arise, will exist for a brief length.

These groups, categories, and zones are crucial for classifying gadget and making sure that it is accurately designed, constructed, and marked to save you ignition resources in potentially explosive atmospheres.

Different areas and international locations may also adopt variations or contain elements of the IEC 60079 series into their nearby standards and guidelines, so it’s important to adhere to the particular requirements applicable to the place in which the equipment is to be used.

Subscribe to our Newsletter “Electrical Insights Daily” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts