IEC Standard for Instrument Earthing: Best Guide

IEC standard for instrument earthing, also referred to as grounding, play a crucial role in ensuring the safety, reliability, and performance of electrical and electronic systems. To achieve these objectives, compliance with the International Electrotechnical Commission or IEC standard for instrument earthing is of utmost importance.

Read More About

IEC Standard for Instrument Earthing

Let’s take a closer look at why adhering to these standards is critical and delve into their key aspects:

IEC Standard for Instrument Earthing Importance: IEC standards for instrument earthing are essential guidelines that define the correct grounding practices for various instruments across diverse applications.

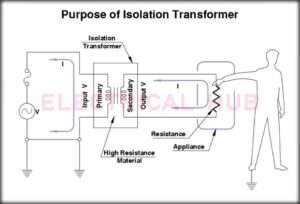

Safety Assurance: The primary focus of IEC standards is safety. Proper instrument earthing ensures that electrical faults are safely directed into the ground, thus preventing potential shock hazards to personnel.

Why instrument earthing is Necessary?

Understanding the impact of electricity on the human body is critical for ensuring safety in electrical systems. The effects of electric current vary depending on its intensity and the path it takes through the body.

Electricity and the Human Body

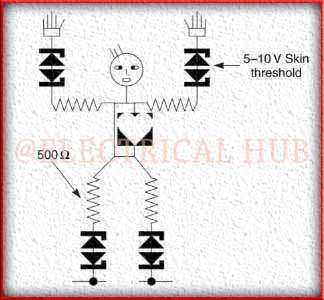

Human limbs possess a resistance of approximately 500 ohms, while the central torso offers a much lower resistance due to its high water content. When electricity penetrates the skin, it behaves somewhat like a Zener diode, with a reverse breakdown voltage typically ranging from 5 to 10 volts. This variation is influenced by individual skin characteristics and whether the skin is dry or greasy.

In the realm of electrical safety, health experts have established certain thresholds. A current as low as 1 milliampere (mA) is often cited as the threshold of sensation. At around 5 mA, an electric shock is described as “disturbing,” causing surprise in the recipient and even potential harm in certain circumstances. Currents in the range of 6-30 mA can lead to temporary paralysis, explaining why individuals often cannot release conductors during a shock.

More severe consequences occur with higher currents. In the range of 1 to 5 amperes (A), ventricular fibrillation can occur, leading to an inefficient pumping of blood by the heart. When a current of 10 A flows through the heart, it can lead to cardiac arrest.

Dangerous Voltage Limit For The Human Body

In practical terms, the likelihood of high-current density flowing through the heart increases when the left hand and right foot serve as the connection points. Hand-to-hand connections can also be fatal.

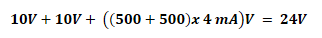

When we consider the body’s resistance in an electrical circuit and aim to ensure safety, it’s generally recommended that a maximum voltage of approximately 24 volts should be encountered by humans. This is based on the worst-case scenario where a mild shock is permissible with a current of 4 mA.

The preference for 24 V supplies for instrument systems is therefore understandable, as they allow working on low-voltage equipment without significant safety concerns. In practice, most people do not feel any sensation below about 40 V.

Although 110 V AC configured as 55-0-55 with the secondary center tapped to earth is common in the United States, it hasn’t been universally adopted due to the popularity of 220/240 V equipment elsewhere.

However, it’s crucial to note that even in low-voltage systems, heat generated at high currents can cause burns, so caution must always be exercised. To maintain safety under normal and fault conditions in a plant, the return path’s resistance should be low enough to prevent voltages exceeding 25 V peak.

IS (Instrument System) earth specification

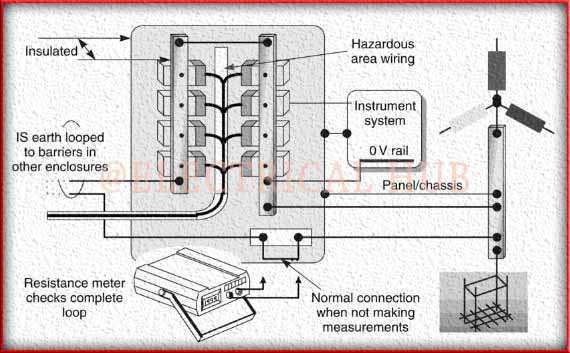

As for Intrinsically Safe (IS) systems, standards like IEC 60079-14 require specific earth connections. The IS earth should be linked back to the earth reference using at least 4 mm2 copper cable with a resistance of less than 12 ohms. This earth should remain separate from other earth systems and must be identified as an IS earth.

A common practice in IS earth installation is using a pair of 10 mm2 cables, which have extremely low resistance over a 100 m run. While the method of identification isn’t standardized, one suggestion is to wrap the cable pair with turns of blue insulating tape every half meter for clarity.

IS earth testing

Furthermore, testing IS Earth using twin parallel conductors is becoming the industry norm. By connecting the IS earth to the earth reference using two conductors, loop integrity can be easily checked by breaking one conductor and measuring or monitoring the loop resistance. This strategy also adds redundancy and lowers overall resistance, enhancing system integrity.

Connecting IS earth from different cabinets may involve looping through, but each interconnecting branch should be verified for integrity. The furthest branch must still meet the requirement of connecting back to the earth reference with a resistance of less than 1 ohm.

500 V isolation test

For circuit isolation, the ability to withstand a 500 Vrms test for an IS circuit conductor has become internationally accepted as a fundamental requirement. IS circuit conductors in a cable must be isolated from Earth and other IS circuits to withstand this test for 1 minute.

In cases where this requirement cannot be met, certain countries’ codes of practice may require special approaches to address the issue. These approaches are detailed further in the application section, where accepted techniques for this scenario are discussed.

IEC 60079-0 Compliance: In environments where explosive gas atmospheres are a concern, adherence to IEC 60079-0 is imperative. This standard establishes general requirements for electrical apparatus and is crucial for instrument earthing in hazardous locations.

IEC 61010-1 and Safety: IEC 61010-1 addresses the safety of electrical equipment and covers grounding and insulation requirements for instruments. Compliance with this standard is crucial, particularly in laboratory, control, and measurement applications.

IEC 60092-507 for Ships: When dealing with instrumentation on ships, following IEC 60092-507 is essential. This standard outlines electrical installation requirements, including proper earthing, to ensure safe maritime operations.

Low Voltage Equipment: IEC 60947-1 is indispensable for those working with low-voltage switchgear and control. It provides guidelines for the earthing and bonding of electrical equipment to ensure safe operation.

IEC 60364-4-41 and Electric Shock Protection: IEC 60364-4-41 focuses on protection against electric shock in low-voltage electrical installations. It underscores the significance of adequate earthing in safeguarding against electric shock.

Comprehensive Guidelines: These IEC standards offer comprehensive guidelines that encompass the selection of grounding materials, connections, and maintenance procedures.

Interference Mitigation: Proper instrument earthing following IEC standards reduces electromagnetic interference. This is crucial in applications where precise measurements and data integrity are paramount.

Grounding Systems: IEC standards specify the use of grounding systems, including grounding electrodes, conductors, and bonding methods, to establish a low-resistance path for fault currents.

Risk Mitigation: Compliance with IEC standards helps mitigate risks associated with electrical faults and lightning strikes by providing precise grounding techniques.

Ongoing Updates: It’s essential to recognize that IEC standards are subject to revisions and updates to align with technological advancements and evolving safety requirements. Staying informed about the latest revisions is crucial.

In summary, adherence to IEC standard for instrument earthing is foundational in upholding a secure, dependable, and interference-free electrical and electronic environment. These standards are meticulously designed to address specific applications and offer detailed guidance for the proper implementation of earthing practices.

Whether you work in hazardous environments, laboratories, ships, or any other setting, ensuring compliance with the relevant IEC standard for instrument earthing is a fundamental component of electrical safety and system performance.

Subscribe to our Newsletter “Electrical Insights Daily” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

- Methods of Electrical Earthing

- Electrical Earthing Important Types

- Earthing Cable Size as Per IEC

- Throttle Position Sensor

- Plant Factor, Plant Capacity Factor, and Load Factor

- Difference Between Demand Factor and Diversity Factor

- Plant Factor, Plant Capacity Factor, and Load Factor

- Buck Converter Interview Questions

- DC DC Converter Interview Questions