Earthing Cable Size as Per IEC: A Comprehensive Guide

The International Electrotechnical Commission (IEC) provides standards for various aspects of electrical and electronic engineering, including those related to earthing (grounding) systems. The size of the earthing (grounding) conductors, such as the earthing cable, is typically determined by local electrical codes and standards that reference IEC standards.

Read More About

Earthing Cable Size as Per IEC

IEC 60364-5-54 is the IEC standard that provides guidelines for earthing systems in electrical installations. The sizing of earthing conductors depends on several factors, including the maximum fault current, the duration of the fault, and the type of soil in which the earthing system is installed.

Factors for Earthing Cable Size as Per IEC

In general, the sizing of earthing conductors is based on the following principles, we will discuss earthing cable size as per IEC 60364-5-54:

Maximum Fault Current: The size of the earthing conductor should be sufficient to safely carry the maximum fault current that could occur in the electrical system. This current is typically determined by the rating of the protective devices (circuit breakers, fuses, etc.) in the system.

Duration of the Fault: The duration of the fault current (short-circuit duration) is also considered. The conductor should be able to handle the fault current without overheating or sustaining damage during the fault.

Soil Resistivity: The resistivity of the soil in which the earthing system is installed is an important factor. In areas with higher soil resistivity, larger earthing conductors may be required to ensure adequate dissipation of fault currents into the ground.

Local Codes and Regulations: Local electrical codes and regulations may provide specific requirements for earthing conductor sizing based on the particular conditions and safety standards in the region.

Methods for earthing cable size as per IEC 60364-5-54

There are two approaches available:

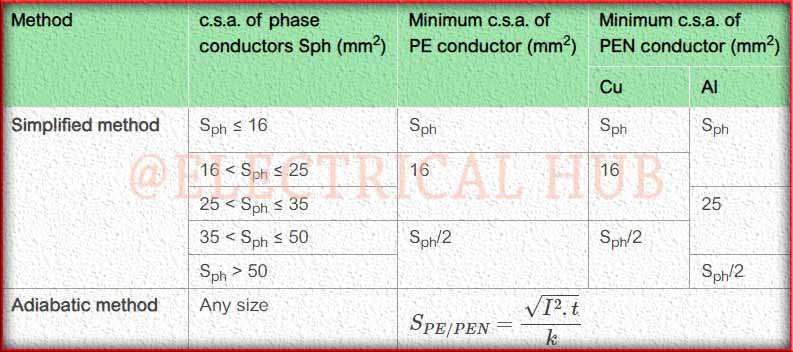

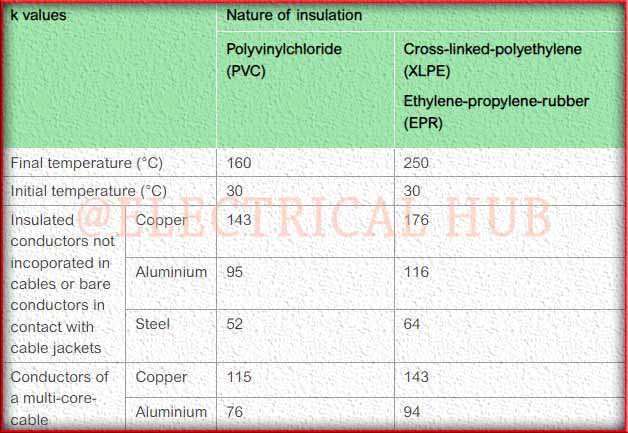

This table presents two methods for calculating the appropriate cross-sectional area (c.s.a.) for a combination of insulating earth (PE) or earthing and neutral (PEN) conductors The integrity of the data depends on the condition that the potential conductor is made of the same material as the line conductor.

Adiabatic Method

This method, at the same time, is cost-powerful and ensures conductor protection in opposition to overheating, frequently affecting smaller cross-sectional regions (c.S.A.) in comparison to the corresponding circuit segment conductors.

This can be incompatible with the imperative to limit impedance inside the circuit earth-fault loop to ensure fast operation via instant overcurrent tripping devices. As a result, this technique is commonly implemented in TT installations and for figuring out the dimensions of an earthing conductor.

Simplified Method

This method simplifies the size of the protective earth (PE) wires by matching them to the size of the corresponding circuit phase conductors, assuming both use the same conductor material.

Where different materials have been used, a correction factor K is required.

When the earthing protective (PE) conductor is physically separated from the circuit phase conductor, the following minimum cross-sectional area values must be observed:

- 2.5 mm² if the PE conductor benefits from mechanical protection.

- 4 mm² if the PE conductor lacks mechanical protection.

For motives related to mechanical considerations, a combined protective earth and impartial (PEN) conductor have to have a cross-sectional location of no much less than 10 mm² in copper or 16 mm² in aluminum.

What is IEC 60364-5-54?

IEC 60364-5-54 is an international standard that provides guidelines and requirements for the grounding and safety of electrical installations in buildings It focuses on ensuring electrical safety and efficiency of electrical systems by setting standards for grounding and cable tie-in practices.

Earthing System Design:

The standard defines how to design an effective earthing system to ensure electrical safety. It covers the selection of earthing electrodes, which are the components buried in the ground to provide a low-resistance path for fault currents. The design takes into account the soil resistivity, the maximum fault current, and the duration of the fault.

Conductor Sizing:

To determine the size of earthing conductors, the standard considers the maximum fault current that could occur in the system. Larger fault currents require larger conductors to dissipate the energy generated during a fault safely.

Protective Bonding:

Protective bonding ensures that all exposed conductive parts, such as metal equipment cases, are properly connected to prevent electrical shock hazards. The standard defines the methods and requirements for protective bonding.

Equipotential Bonding:

Equipotential bonding ensures that all exposed conductive parts and metal structures have the same electrical potential. This helps prevent differences in potential that could lead to electric shock. The standard provides guidelines for maintaining uniform electrical potential within an installation.

Protection Against Electric Shock:

The standard outlines measures to limit touch and step voltages during a fault condition, thus protecting individuals from electric shock.

Lightning Protection:

It includes requirements for lightning protection systems and their connection to the earthing system. Lightning protection involves the safe dissipation of lightning-induced currents to the ground.

Testing and Verification:

The standard specifies procedures for testing and verifying the effectiveness of the earthing and bonding systems to ensure that they meet safety and performance requirements.

It’s essential to consult with local electrical authorities and follow local codes and standards when determining the size of earthing conductors for a specific installation. Additionally, a qualified electrical engineer should be involved in the design of the earthing system to ensure that it meets safety and performance requirements.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

References:

Electrical Installation Guide By Commission électrotechnique internationale · 2008