11 Different Types of Fuses and Their Applications: Important Guide

Fuses play a pivotal role in electrical systems by safeguarding circuits and devices from overcurrent conditions. They serve as essential components that prevent electrical fires and equipment damage. There are various types of fuses available, each tailored to specific applications and requirements.

Read More

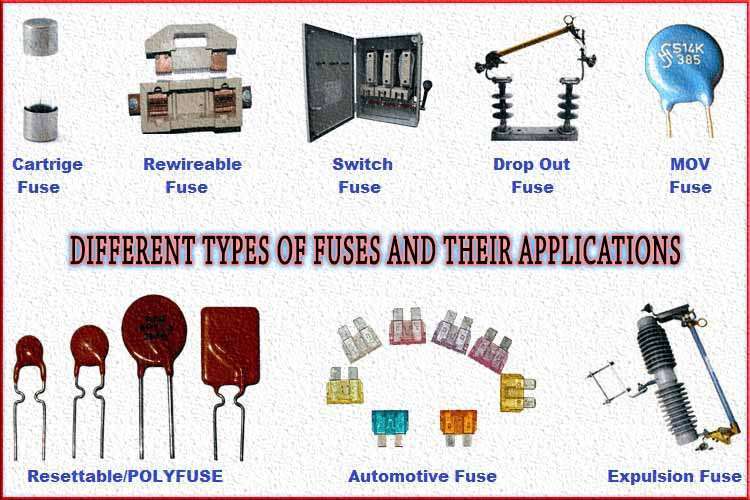

Different Types of Fuses and Their Applications

Looking for insights into the different types of fuses and their applications? Read on to explore the significance of different types of fuses and their applications in various industries. Learn how HRC fuses, cartridge fuses, semiconductor fuses, and more ensure safety and protection in diverse electrical systems.

In this article, we will delve into the different types of fuses and their applications, shedding light on their significance in various industries.

Different Types of Fuses and Their Applications

1. Cartridge Fuses

Cartridge fuses are cylindrical fuses with metal end caps that come in various sizes and current ratings. They are used in industrial applications, power distribution, and electrical panels. The body material can be ceramic or glass, offering different levels of protection and voltage ratings. These fuses can be either fast-acting or time-delay (slow-blow) based on their internal design.

2. Blade Fuses

Blade fuses are commonly used in automotive and vehicle electrical systems. They have a flat, blade-like design and are inserted into fuse holders. They are color-coded based on their current rating for easy identification. These fuses are easily replaceable and widely used in vehicles and low-voltage applications.

3. Resettable Fuses (PTC Fuses)

PTC fuses, also known as resettable fuses or polymeric positive temperature coefficient fuses, use a thermistor to limit current flow. When the current exceeds a certain threshold, the thermistor’s resistance increases, reducing the current flow. Once the fault is cleared, the thermistor cools down and its resistance decreases, allowing the fuse to reset itself.

4. Thermal Fuses

Thermal fuses are designed to prevent overheating in appliances and electronics. They contain a heat-sensitive material that melts at a specific temperature, breaking the circuit and preventing further current flow. These fuses are used in devices like irons, hairdryers, and other household appliances.

5. Miniature Circuit Breakers (MCBs)

MCBs are automatic switches that protect against overcurrent conditions. Unlike traditional fuses, MCBs can be manually reset after tripping. They are commonly used in residential and commercial electrical systems to provide both short-circuit and overcurrent protection.

6. High-Voltage Fuses

High-voltage fuses are designed to handle higher voltage levels, commonly found in power transmission and distribution systems. These fuses are built to safely interrupt fault currents of substantial magnitudes and prevent damage to equipment.

7. HRC (High Rupturing Capacity) Fuses

HRC fuses are used to protect larger electrical systems. They have a high interrupting capacity, which means they can safely interrupt high fault currents without causing damage. These fuses are commonly used in industrial environments where large amounts of power are involved.

8. Fuse Links

Fuse links are designed to melt quickly in response to overcurrent conditions. They are used in distribution networks, transformers, and other systems to protect downstream equipment by interrupting the circuit in the event of a fault.

9. Semiconductor Fuses

Semiconductor fuses are specifically designed to protect sensitive semiconductor devices like diodes, transistors, and thyristors from overcurrent conditions. These fuses are optimized to operate in coordination with semiconductor devices’ characteristics.

10. SMD (Surface Mount Device) Fuses:

SMD fuses are designed to be mounted directly onto the surface of a circuit board. They have small form factors and are commonly used in modern electronics, where space is limited.

11. High-Speed Fuses:

High-speed fuses are used to protect sensitive electronic components from short circuits and overcurrent conditions. They are designed to interrupt the circuit quickly to prevent damage to the components.

Selection table of Different Types of Fuses

Here’s a table outlining the selection parameters for each type of fuse:

| Fuse Type | Application | Voltage Rating | Current Rating | Speed of Operation | Resettable |

| Cartridge Fuses | Industrial, Panels | Low to High | Low to High | Fast or Time-Delay | No |

| Blade Fuses | Automotive, Low Voltage | Low | Low to Moderate | Fast | No |

| Resettable (PTC) Fuses | Electronics | Low to Moderate | Low to Moderate | Slow | Yes |

| Thermal Fuses | Appliances, Electronics | Low to Moderate | Low to Moderate | Fast | No |

| Miniature Circuit Breakers | Residential, Commercial | Low to Moderate | Low to High | Fast | Yes |

| High-Voltage Fuses | Power Transmission | High | High | Slow | No |

| HRC Fuses | Industrial, Large Systems | High | High | Slow | No |

| Fuse Links | Distribution, Transformers | Low to High | Low to High | Fast | No |

| Semiconductor Fuses | Electronics | Low to Moderate | Low to Moderate | Fast | No |

| SMD Fuses | Electronics | Low to Moderate | Low to Moderate | Fast | No |

| High-Speed Fuses | Electronics | Low to Moderate | Low to High | Very Fast | No |

In conclusion, understanding the different types of fuses and their applications is crucial for ensuring the safety and efficiency of electrical systems across various industries.

From the robust protection offered by HRC fuses in industrial settings to the precise safeguarding provided by semiconductor fuses in electronics, each type plays a pivotal role. Implementing the appropriate fuse type according to the specific requirements of the application is a fundamental step toward maintaining reliable and secure electrical systems.

Worth Read Posts

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.