Fast Blow vs Slow Blow Fuse: A Detailed Overview

Fast blow vs slow blow fuse refers to two distinct types of fuses employed in electrical circuits, each with unique characteristics that cater to specific operational needs and protection requirements.

Read More About

Fast Blow vs Slow Blow Fuse

Fast Blow Fuse:

A fast blow fuse, also known as a fast-acting fuse, operates with rapid responsiveness upon detecting overcurrent situations. These fuses are designed to swiftly interrupt the circuit when faced with a sudden surge or spike in current. Their key attributes include:

Immediate Disconnection: Fast blow fuses excel in quickly disconnecting the circuit upon encountering excess current, safeguarding sensitive electronic components, control modules, or other delicate devices against potential damage.

Sensitivity to Overcurrent: They are highly sensitive to abrupt increases in current, making them a preferred choice for applications where instantaneous protection is critical, such as in digital circuits, computers, or precision instruments.

Amperage Range: Available in a wide range of amperage ratings, from lower ratings (1-5A) for sensitive electronics to higher ratings (30A+) for heavy-duty circuits, offering diverse options for various applications.

Slow Blow Fuse:

Contrarily, slow blow fuses, also termed time-delay fuses, possess a delayed response to overcurrent situations. These fuses are designed to tolerate temporary surges or inrush currents, allowing a brief time delay before interrupting the circuit. Key features include:

Tolerance to Transient Currents: Slow blow fuses are designed to withstand short-term surges of current without immediately tripping. This delay helps accommodate temporary overcurrents often seen during equipment startup or specific operational conditions.

Gradual Disconnection: They provide a measured response to overcurrents, distinguishing between normal startup power surges and sustained overloads, thereby preventing unnecessary disruptions during temporary current spikes.

Amperage Range: Available in a variety of ratings (1-40A+), slow blow fuses are suitable for appliances, motors, or equipment with intermittent high-power demands, offering tailored protection against transient currents.

Difference between Fast Blow vs Slow Blow Fuse:

The core distinction between these fuses lies in their response time to overcurrent situations. Fast blow fuses offer swift and immediate disconnection, ideal for protecting sensitive electronics. In contrast, slow blow fuses provide a delayed response, accommodating temporary surges common in specific equipment or startup sequences without triggering prematurely.

Choosing between fast blow vs slow blow fuse depends on the specific circuit’s operational requirements, sensitivity to overcurrent, and tolerance towards brief current surges. It’s crucial to match the appropriate fuse type and rating to ensure optimal protection and reliable operation of electrical systems and devices.

fast blow vs slow blow fuse applications

The choice between Fast Blow vs Slow Blow Fuse hinges on their distinct applications, each tailored to specific electrical scenarios:

Fast Blow Fuse Applications:

Sensitive Electronics: Fast Blow vs Slow Blow Fuses are essential for safeguarding delicate electronic circuits against sudden spikes in current. They find application in:

- Control modules

- Microprocessors

- Integrated circuits

- Consumer electronics

Precision Instruments: Equipment requiring stable power without any abrupt disruptions benefits from fast blow fuses, including:

- Laboratory instruments

- Measurement devices

- Testing equipment

Digital Circuits: Circuits that can’t tolerate any deviations in current employ fast blow fuses:

- Digital control systems

- Advanced computing devices

- Data centers and servers

Slow Blow Fuse Applications:

Motorized Equipment: Slow blow fuses accommodate startup surges in devices with motors, preventing unnecessary tripping during:

- Refrigerator compressors

- Air conditioner units

- Industrial pumps

Inrush Currents: Circuits with components needing a brief but intense power surge benefit from slow blow fuses in:

- Equipment with capacitors (e.g., power supplies)

- Devices with initial power demands higher than their operational needs

Power-Hungry Devices: Slow blow fuses suit equipment with intermittent high-power demands:

- Power tools

- Heavy-duty machinery

- Certain automotive systems

Differentiation in Applications:

Fast Blow Fuse: Immediate protection for sensitive electronics against sudden current spikes.

Slow Blow Fuse: Tolerates short-term current surges during startup or in specific operational conditions without triggering prematurely.

Selecting between fast blow vs slow blow fuse relies on understanding the circuit’s nature, its susceptibility to current fluctuations, and the necessity for immediate versus delayed response to overcurrent situations. Matching the right fuse type ensures effective protection, preventing damage to components and preserving the system’s integrity.

fast blow or slow blow fuse for amplifier

The selection between a fast blow and a slow blow fuse for an amplifier depends on the amplifier’s specific characteristics and operational needs:

Fast Blow Fuse for Amplifier:

Consider using a fast blow fuse for an amplifier if:

- Your amplifier comprises sensitive components that require immediate protection against sudden spikes in current.

- The amplifier’s circuitry is designed to be highly responsive and can’t tolerate any abrupt increase in current.

- Immediate disconnection upon detecting overcurrent is crucial to prevent damage to delicate electronic parts.

Slow Blow Fuse for Amplifier:

Opt for a slow blow fuse for an amplifier if:

- The amplifier exhibits high startup currents or experiences transient surges during power-on sequences.

- There’s a need to accommodate brief but intense surges in current without triggering the fuse prematurely.

- Providing a delay before interrupting the circuit during temporary overcurrent situations is beneficial to avoid unnecessary disruptions.

In essence, for an amplifier, the choice between fast blow vs slow blow fuse depends on the amplifier’s sensitivity to current fluctuations during operation, particularly during startup, and the necessity for immediate versus delayed response to overcurrent situations. Evaluating the amplifier’s specifications and operational behavior will guide the appropriate fuse selection, ensuring the optimal balance between protection and uninterrupted operation of the amplifier.

tables for selection of Fast Blow vs Slow Blow Fuse

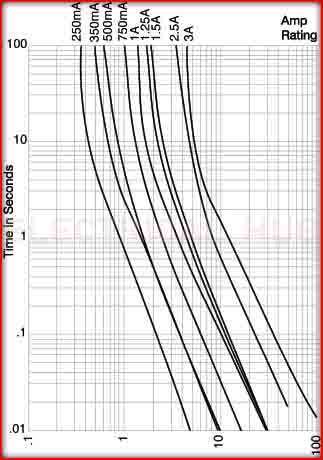

Below are the characteristics of low current fuses which shows as the time and fusing element current bearing capacity. As the time increases fusing capacity starts decreasing. From this curve we can have an idea that which rated fuse can withstand for how much time.

Here are tables illustrating ratings and selection criteria for both Fast Blow vs Slow Blow Fuse:

Fast Blow Fuse Selection Guide:

| Fuse Rating (Amperes) | Typical Applications |

| 1-5A | Sensitive electronics, control modules, sensors |

| 5-15A | Audio equipment, small motors, lighting systems |

| 15-30A | Power supplies, larger motors, heavy-duty electronics |

| 30A+ | High-power circuits, automotive systems, industrial machinery |

Criteria for Fast Blow Fuse Selection:

Application Type: Determine the sensitivity of the circuit and the level of protection needed against sudden spikes in current.

Amperage Requirements: Assess the circuit’s current requirements under normal operating conditions and choose a fuse rating slightly higher than the average current for protection.

Component Sensitivity: Consider the vulnerability of sensitive electronic components to overcurrent, necessitating immediate disconnection.

Slow Blow Fuse Selection Guide:

| Fuse Rating (Amperes) | Typical Applications |

| 1-10A | Appliances with inrush currents (motors, pumps, refrigerators) |

| 10-20A | Power tools, equipment with intermittent high-power demands |

| 20-40A | Industrial machinery, certain automotive systems |

| 40A+ | Specific applications requiring delayed response to inrush currents |

Criteria for Slow Blow Fuse Selection:

Startup Requirements: Evaluate the equipment’s startup behavior and identify instances of inrush current that need tolerance.

Operating Conditions: Consider periodic surges or fluctuations in current that are part of normal operation.

Device Protection: Balance between immediate disconnection and allowing temporary surges without tripping the fuse unnecessarily.

These tables and selection criteria provide a basic guideline for choosing fast blow or slow blow fuses based on their respective amperage ratings and typical applications. However, for precise selection, always refer to the manufacturer’s recommendations and specifications related to the specific circuit or equipment to ensure optimal fuse selection and protection.

fast blow vs slow blow automotive fuse ratings

In automotive applications, both Fast Blow vs Slow Blow Fuse fuses serve distinct purposes based on the requirements of the circuit.

The ratings for these fuses differ to accommodate specific needs:

Fast Blow Automotive Fuse Ratings:

Fast blow fuses used in automotive systems typically have ratings that align with the immediate protection needed for sensitive electronic components or critical circuits. Ratings for fast blow automotive fuses can range from 1 amp to 40 amps or more, depending on the specific application. For instance:

Low Amp Ratings (1-15A): These fuses might be found in circuits protecting sensitive electronics like control modules, sensors, or smaller electrical components. They provide rapid protection against short circuits or sudden spikes in current to prevent damage.

Medium to High Amp Ratings (15-40A+): Applications requiring higher power, such as certain motors, lighting systems, or larger electrical components, may use fast blow fuses in this range. They swiftly interrupt the circuit upon detecting overcurrent to prevent damage or hazards.

Slow Blow Automotive Fuse Ratings:

Slow blow fuses in automotive circuits are tailored to tolerate short-term overcurrent situations typically associated with certain equipment or startup conditions. Their ratings might vary based on the expected inrush currents or temporary surges. These could range from 1 amp to higher values, much like fast blow fuses, but they’re primarily selected for specific applications:

Higher Amp Ratings (15-40A+): Slow blow fuses within this range might be utilized in circuits where temporary overcurrents are expected during equipment startup, such as with certain motors, heating elements, or power-hungry components. They provide a delayed response to accommodate these temporary surges.

Varied Ratings for Specific Needs: Slow blow automotive fuses might have diverse ratings based on the unique requirements of the automotive system, accommodating inrush currents in specific circuits without causing unnecessary interruptions or premature tripping.

These fuse ratings illustrate how both Fast Blow vs Slow Blow Fuse serve different functions in automotive applications, offering immediate protection or delayed response, respectively, based on the demands of the electrical system within a vehicle.

types of fast blow fuses

Fast blow fuses come in various types, each designed for specific applications based on their construction and characteristics. Here’s a simplified table to illustrate the types of fast blow fuses and their characteristics:

| Fuse Type | Description | Applications |

| Glass Tube Fast Blow Fuse | Cylindrical fuse with a glass tube housing | Electronic circuits, consumer electronics |

| Ceramic Fast Blow Fuse | Constructed with a ceramic body for stability | Industrial applications, higher currents |

| Surface Mount Fast Blow Fuse | Mounted directly on PCBs for space-saving | Modern electronics, compact designs |

| Cartridge Fast Blow Fuse | Larger cylindrical design for high-power scenarios | Industrial machinery, power distribution |

These types differ in their physical construction, material composition, and intended applications, catering to various needs across electronics, industrial machinery, and power systems. Selecting the appropriate type depends on the specific requirements of the circuit, the amount of current it handles, and the space constraints within the system.

types of slow blow fuses

Slow blow fuses are designed to tolerate temporary surges in current before interrupting the circuit. Here’s a simplified table illustrating the types of slow blow fuses and their characteristics:

| Fuse Type | Description | Applications |

| Glass Tube Slow Blow Fuse | Glass tube housing with delayed response | Electronic circuits, appliances |

| Ceramic Slow Blow Fuse | Ceramic body, higher current tolerance | Industrial machinery, high-power applications |

| Resettable Polymeric PTC Fuse | Polymer-based, resettable after fault removal | Certain electronic applications |

| Cartridge Slow Blow Fuse | Large cartridge design, delayed response to overcurrent | Heavy machinery, industrial systems |

These variations cater to different applications based on their construction, current-carrying capacity, and the capability to withstand temporary overcurrent situations. The choice of a slow blow fuse type depends on the specific requirements of the circuit, including its operational characteristics and tolerance towards transient current surges.

Conclusion

In summary, the selection between Fast Blow vs Slow Blow Fuse is pivotal in ensuring the optimal protection and functionality of electrical circuits across diverse applications.

Fast blow fuses provide immediate disconnection upon detecting overcurrent, making them ideal for safeguarding sensitive electronics and precise instruments from abrupt spikes in current.

Slow blow fuses, on the other hand, offer a delayed response, tolerating temporary surges or inrush currents commonly encountered during equipment startup or specific operational conditions, preventing premature tripping.

Understanding the distinct characteristics and applications of these fuses is crucial. Fast blow fuses excel in rapid, precision-focused protection for delicate electronics, while slow blow fuses accommodate temporary current fluctuations without unnecessary interruptions in a broader range of equipment.

Ultimately, selecting the right fuse type, whether fast blow or slow blow, involves assessing the circuit’s requirements, sensitivity to overcurrent, and tolerance towards transient surges. This informed decision ensures effective protection, preserves the integrity of electrical systems, and prevents damage to critical components, thereby optimizing the reliability and longevity of the circuits they safeguard.

What’s the main difference between a fast blow and a slow blow fuse?

The primary difference lies in their response time to overcurrent situations. Fast blow fuses disconnect swiftly upon detecting excess current, while slow blow fuses provide a delayed response to tolerate temporary surges.

When should I use a fast blow fuse?

Fast blow fuses are ideal for protecting sensitive electronics that can’t handle sudden spikes in current. They’re suitable for digital circuits, microprocessors, and control modules.

What are the typical applications of slow blow fuses?

Slow blow fuses find use in equipment that experiences startup surges or intermittent high-power demands. They’re often seen in appliances with motors, industrial machinery, and power tools.

How do I choose between a fast blow and a slow blow fuse for my circuit?

Assess the circuit’s sensitivity to overcurrent, startup behavior, and the necessity for immediate or delayed response. Fast blow fuses offer swift protection, while slow blow fuses tolerate brief but intense surges.

Are slow blow fuses less protective than fast blow fuses?

Not necessarily. Slow blow fuses provide delayed response deliberately to accommodate temporary surges without sacrificing protection, whereas fast blow fuses respond immediately.

Can I interchange fast blow and slow blow fuses in a circuit?

It’s not recommended as they serve different purposes. Changing fuses might compromise protection—fast blow for immediate response and slow blow for transient surge tolerance.

What factors should I consider while selecting between fast blow and slow blow fuses?

Consider the circuit’s operational behavior, the level of sensitivity to current spikes, and the tolerance towards temporary surges to make an informed choice.

Are there specific industries where one type of fuse is more commonly used than the other?

Yes, for instance, fast blow fuses are prevalent in electronics and precision instruments, while slow blow fuses are frequently found in appliances, industrial machinery, and power systems.

Worth Read Posts

Subscribe to our Newsletter “Electrical Insights Daily” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.