Touch Sensors: A Comprehensive Guide

In our increasingly interconnected and digital era, touch sensors stand as silent conduits between the tangible and the virtual. These sensors, with their intuitive capacity to respond to human touch, have revolutionized the way we interact with technology. Whether embedded in our smartphones, interactive displays, or household appliances, touch sensors have become a necessity, facilitating seamless and tactile user experiences.

Read More About

At its core, a touch sensor is a specialized technology that detects and responds to physical contact or proximity, translating these interactions into actionable input for electronic devices. The evolution of touch sensing technology has gone beyond simple buttons or switches, offering a spectrum of sophisticated solutions, each designed to cater to specific applications and user expectations.

This exploration into touch sensors will unravel the intricacies of their working principles, the diverse types that exist, and the wide array of applications they serve. From capacitive touchscreens to pressure-sensitive pads, the realm of touch sensors encompasses an array of technologies that have redefined user interfaces, making them more intuitive, responsive, and immersive.

Join us on a journey into the world of touch sensors, where human touch becomes a powerful language that bridges the physical and digital realms, transforming how we engage with the technologies that enrich our daily lives.

Working principle of Touch Sensors

Touch sensors operate based on various principles, and the working principle depends on the specific technology employed. Here are the working principles of two common types of touch sensor technologies:

Capacitive Touch Sensors:

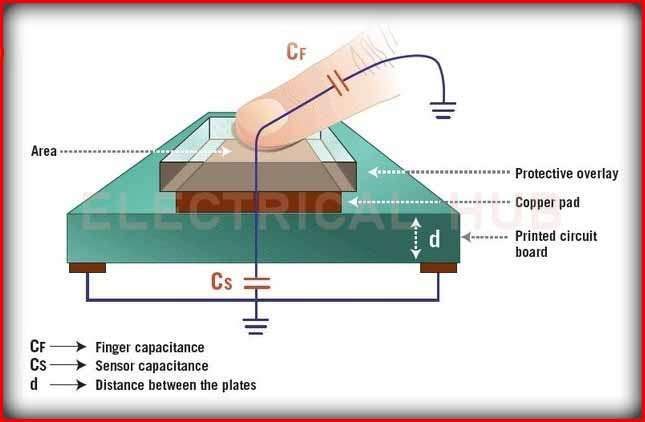

Working Principle: Capacitive touch sensors operate on the principle of capacitance, which is the ability of a system to store an electric charge. These sensors consist of a touch-sensitive surface, often made of glass or other materials, that is coated with a transparent conductor like indium tin oxide (ITO). An electric charge is constantly applied to this surface, creating an electrostatic field.

Operation Steps:

- The touch sensor’s surface is constantly supplied with an AC (alternating current) signal, creating an electrostatic field.

- When a conductive object, such as a finger, comes into contact with or close proximity to the surface, it disrupts the electrostatic field.

- The change in capacitance at the touch point is detected by the sensor’s controller.

- The controller processes this information to determine the touch location.

- High sensitivity and accuracy.

- Suitable for various surfaces, including glass and plastic.

- Supports multi-touch functionality.

- Susceptible to environmental factors such as humidity and temperature.

- Requires a conductive object for activation.

Resistive Touch Sensors:

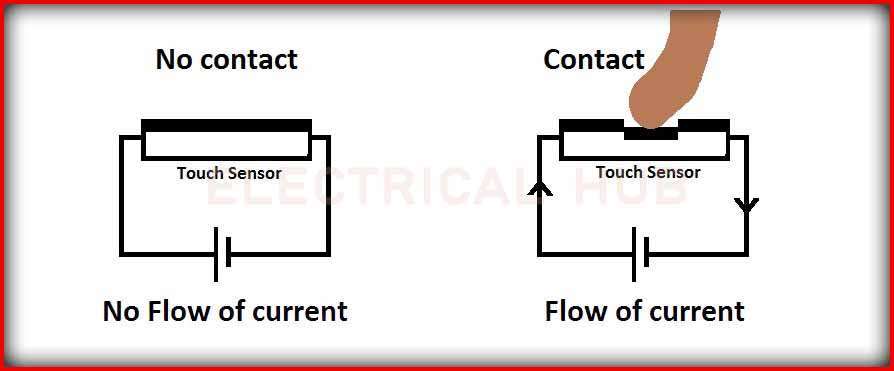

Working Principle: Resistive touch sensors consist of multiple layers, typically two flexible layers separated by a small gap. The inner surfaces of these layers are coated with a resistive material, and they are separated by insulating dots. When pressure is applied to the top layer, it makes physical contact with the bottom layer, creating a circuit.

Operation Steps:

- The top layer, known as the flexible or conductive layer, remains in electrical contact with the bottom layer through a series of resistive elements.

- When pressure is applied, the top layer deforms, causing it to come into direct contact with the bottom layer at a specific point.

- The point of contact alters the resistance at that location, which is measured by the touch sensor’s controller.

- The controller interprets the resistance change to determine the touch location.

- Simple and cost-effective.

- Operable with various objects, including fingers, styluses, or gloved hands.

- Limited accuracy and sensitivity compared to capacitive sensors.

- Prone to wear and tear due to physical contact.

- Lower light transmission, impacting display clarity.

Understanding the working principles of touch sensors is crucial for designing responsive touch interfaces in various electronic devices, ranging from smartphones and tablets to industrial control panels and interactive displays.

Types of Touch Sensors:

Touch sensors come in various types, each employing different technologies to detect touch or proximity.

Here are some common types of touch sensors:

Capacitive Touch Sensors:

Technology: Based on the principle of capacitance.

Working: Detects changes in capacitance when a conductive object, like a finger, comes into contact with or close proximity to the sensor surface.

Applications: Touchscreens on smartphones, tablets, interactive displays, touch-sensitive buttons.

Resistive Touch Sensors:

Technology: Comprises multiple layers with a resistive material.

Working: Pressure on the surface causes the top layer to make contact with the bottom layer, altering resistance at the touch point.

Applications: Some older touchscreens, point-of-sale systems, and industrial control panels.

Surface Acoustic Wave (SAW) Touch Sensors:

Technology: Relies on the propagation of ultrasonic waves across the surface.

Working: The disruption of ultrasonic waves by touch is detected to determine the touch location.

Applications: High-quality displays, information kiosks, interactive digital signage.

Infrared Touch Sensors:

Technology: Uses arrays of infrared light-emitting diodes (LEDs) and photodetectors.

Working: Infrared beams create a grid, and interruption by touch is detected to pinpoint the location.

Applications: Large interactive displays, gaming consoles, public information kiosks.

Optical Touch Sensors:

Technology: Utilizes optical image sensors.

Working: Captures images of the surface, and touch is detected by analyzing changes in the captured images.

Applications: Public displays, interactive whiteboards, educational technology.

Projected Capacitive Touch Sensors:

Technology: An advanced form of capacitive touch technology.

Working: Utilizes a grid of electrodes and measures changes in capacitance at each intersection for precise touch tracking.

Applications: Modern smartphones, tablets, high-end touch displays.

Surface Capacitive Touch Sensors:

Technology: Similar to capacitive touch but with a conductive coating on the sensor surface.

Working: Measures changes in capacitance when a conductive object interacts with the coated surface.

Applications: Public kiosks, industrial control panels.

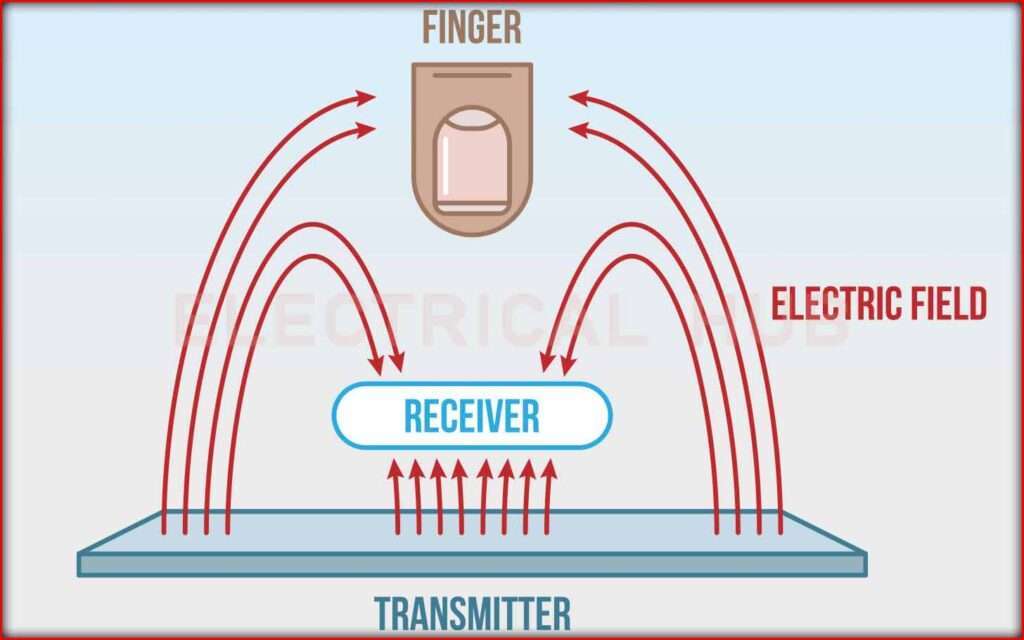

Self-Capacitive Touch Sensors:

Technology: A type of capacitive touch where a single layer acts as both the transmitter and receiver of the electrical signal.

Working: Measures changes in self-capacitance to detect touch.

Applications: Small touch-sensitive surfaces, wearables, touch-sensitive buttons.

Mutual-Capacitive Touch Sensors:

Technology: Another type of capacitive touch where separate layers serve as transmitters and receivers.

Working: Measures changes in mutual capacitance for higher sensitivity and multi-touch capabilities.

Applications: Advanced touchscreens, high-end devices with multi-touch support.

These touch sensor technologies cater to a wide range of applications, from consumer electronics and industrial control to interactive displays and public information systems. The choice of a specific touch sensor type depends on factors such as sensitivity requirements, environmental conditions, and the intended use case.

touch sensors Arduino

Touch sensors with Arduino can be implemented using various technologies, and one of the common methods is by utilizing capacitive touch sensing. Capacitive touch sensors are capable of detecting touch or proximity by measuring changes in capacitance.

Here’s a basic guide on how to implement touch sensors with Arduino using capacitive touch:

Components Needed:

- Arduino board (e.g., Arduino Uno)

- Capacitive touch sensor module (e.g., TTP223)

- Jumper wires

Wiring Steps:

- Connect the VCC pin of the touch sensor to the 5V pin on the Arduino.

- Connect the GND pin of the touch sensor to the GND pin on the Arduino.

- Connect the OUT pin of the touch sensor to a digital pin on the Arduino (e.g., D2).

Arduino Code:

Use the Arduino IDE to write and upload code to your Arduino board.

Here is a simple example code:

const int touchPin = 2; // Pin connected to the OUT pin of the touch sensor

void setup() {

Serial.begin(9600);

pinMode(touchPin, INPUT);

}

void loop() {

int touchValue = digitalRead(touchPin);

if (touchValue == HIGH) {

Serial.println("Touch detected!");

// Add your desired actions when touch is detected

}

delay(100); // Adjust the delay based on your requirements

}

Uploading and Testing:

- Connect your Arduino board to your computer and upload the code.

- Open the Serial Monitor in the Arduino IDE (Tools > Serial Monitor).

- Touch the sensor, and you should see “Touch detected!” messages in the Serial Monitor.

Customization:

You can customize the code to perform specific actions when a touch is detected. For example, turning on an LED, playing a sound, or controlling other devices.

Power Considerations:

Ensure that your touch sensor module and Arduino are adequately powered. If using batteries, make sure they provide sufficient voltage.

- Capacitive touch sensors are sensitive to the environment, and factors like humidity and interference can affect their performance.

- Experiment with different touch sensor modules and adjust sensitivity settings if available on your module.

This is a basic example, and you can explore more advanced features and libraries based on your specific project requirements. Always refer to the datasheets of your touch sensor module for detailed information and specifications.

touch pressure sensor Arduino

If you want to implement a touch pressure sensor with Arduino, you’ll typically use a force-sensitive resistor (FSR) or a capacitive touch sensor with pressure sensitivity. Here, I’ll provide a guide for using an FSR with Arduino as an example.

Components Needed:

- Arduino board (e.g., Arduino Uno)

- Force-sensitive resistor (FSR)

- Resistor (around 10k ohms)

- Jumper wires

Wiring Steps:

- Connect one leg of the FSR to the 5V pin on the Arduino.

- Connect the other leg of the FSR to the A0 analog input pin on the Arduino.

- Connect the FSR to a 10k ohms resistor, and connect the other end of the resistor to the ground (GND) on the Arduino.

- Connect a wire between the junction of the FSR and the resistor to the A0 pin on the Arduino.

Arduino Code:

Use the Arduino IDE to write and upload code to your Arduino board.

Here is a simple example code:

const int fsrPin = A0; // Pin connected to the FSR

void setup() {

Serial.begin(9600);

}

void loop() {

int fsrValue = analogRead(fsrPin);

// Print the FSR value to the Serial Monitor

Serial.println("FSR Value: " + String(fsrValue));

// Add your custom actions based on the FSR value

// For example, control the brightness of an LED based on pressure

delay(100); // Adjust the delay based on your requirements

}

Uploading and Testing:

- Connect your Arduino board to your computer and upload the code.

- Open the Serial Monitor in the Arduino IDE (Tools > Serial Monitor).

- As you apply pressure to the FSR, you should see varying values in the Serial Monitor.

Customization:

Based on the FSR values, you can implement custom actions. For example, controlling the brightness of an LED, triggering a servo motor, or any other application based on pressure.

Calibration:

You might need to calibrate the sensor according to your specific application. Calibrating involves mapping the raw sensor values to meaningful pressure levels.

Applications of Touch Sensors:

Consumer Electronics: Touch sensors are integral to smartphones, tablets, laptops, and smartwatches, providing users with an intuitive and interactive interface.

Industrial Control Systems: In manufacturing environments, touch sensors are used in control panels and human-machine interfaces, enhancing operational efficiency.

Retail and Hospitality: Interactive kiosks and self-service terminals utilize touch sensors, simplifying transactions and improving customer engagement.

Healthcare Devices: Medical equipment often incorporates touch sensors for user-friendly interfaces, contributing to efficient patient care.

Automotive Displays: Touch sensors play a crucial role in modern car infotainment systems and interactive dashboards, providing drivers with seamless control.

Conclusion:

Touch sensors have revolutionized human-computer interaction, making devices more user-friendly and responsive. As technology advances, touch sensors are poised to evolve further, ensuring that our interaction with digital interfaces remains both intuitive and efficient. Whether in our pockets, workplaces, or automobiles, the impact of touch sensors is pervasive, shaping a more connected and interactive future.

1. What is a touch sensor?

A touch sensor is a type of input device that detects touch or pressure on its surface. It is commonly used in electronic devices to register user interactions.

2. How do touch sensors work?

3. What are the types of touch sensors?

4. What is the difference between capacitive and resistive touch sensors?

5. Where are touch sensors commonly used?

Touch sensors are commonly used in smartphones, tablets, laptops, ATMs, kiosks, industrial control panels, and other interactive electronic devices.

6. Can touch sensors work with gloves?

7. How can I calibrate a touch sensor?

Calibration methods vary by device, but many devices have built-in calibration tools in their settings. Follow the manufacturer’s guidelines or refer to the user manual for specific instructions.

8. What are multi-touch sensors?

Multi-touch sensors can detect and respond to multiple simultaneous touch points. This technology is commonly used in smartphones and tablets to enable gestures like pinch-to-zoom and multi-finger swiping.

9. Can touch sensors be used in outdoor environments?

10. How durable are touch sensors?

The durability of sensors depends on the type and quality of the sensor. Capacitive touchscreens are generally more durable than resistive ones. Proper care and maintenance can also contribute to longevity.

Worth Read Posts

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.