Wind Turbine Design Project: Best Guide

The development of a wind turbine design project represents a crucial step forward in sustainable energy production. As renewable energy continues to gain momentum worldwide, understanding the intricacies of wind turbine design becomes increasingly important for engineers and energy professionals. This comprehensive guide explores the essential elements of planning, executing, and optimizing a wind turbine design project.

Table of Contents

Understanding the Fundamentals of Wind Turbine Design Projects

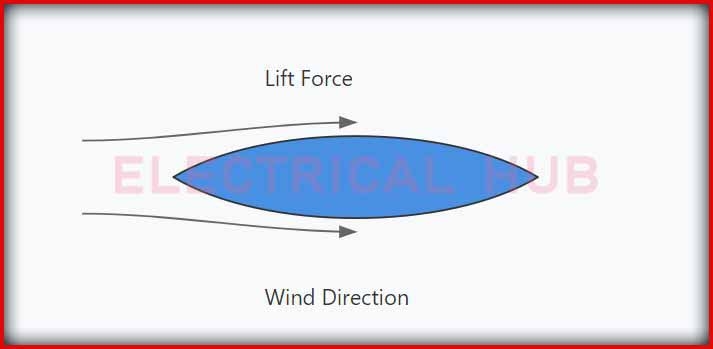

Before diving into the technical aspects, it’s essential to grasp the basic principles that govern wind turbine design projects. Wind turbines convert kinetic energy from moving air into mechanical energy, which is then transformed into electrical power. The success of a wind turbine design project depends heavily on careful consideration of aerodynamics, structural integrity, and environmental factors.

The power output of a wind turbine can be calculated using the following equation:

P = ½ × ρ × A × V³ × Cp

Where:

- P = Power output (watts)

- ρ = Air density (typically 1.225 kg/m³ at sea level)

- A = Swept area of the rotor (m²)

- V = Wind velocity (m/s)

- Cp = Power coefficient (maximum theoretical value is 0.593, known as the Betz limit)

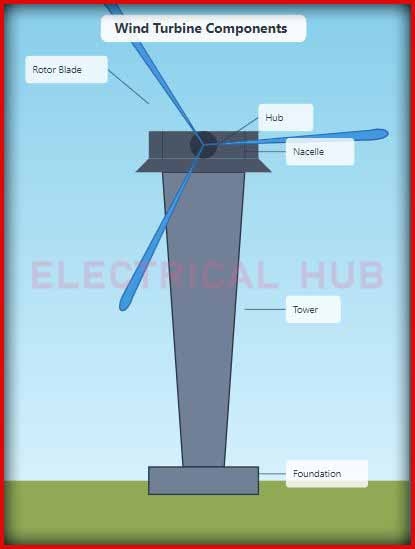

Essential Components in Wind Turbine Design Projects

The success of any wind turbine design project hinges on the careful selection and integration of various components:

Rotor System Design

The rotor system, consisting of blades and hub, requires extensive aerodynamic modeling. Modern blade designs utilize composite materials like fiberglass and carbon fiber, offering an optimal balance between strength and weight. The blade profile typically follows the NACA airfoil series, with thickness-to-chord ratios varying from root to tip.

Blade length calculation follows the relation:

R = √(P × 2)/(ρ × π × V³ × Cp)

Where R is the blade length in meters.

Nacelle Architecture

The nacelle houses critical components including:

- Gearbox (with typical ratio 1:90)

- Generator (either DFIG or permanent magnet)

- Yaw system

- Cooling systems

- Control electronics

Advanced Aerodynamic Considerations

Modern wind turbine design projects incorporate sophisticated aerodynamic principles:

Tip Speed Ratio Optimization

The optimal tip speed ratio (λ) typically ranges between 6-8 for three-bladed turbines:

λ = (ω × R)/V

Where:

- ω = Angular velocity (rad/s)

- R = Blade length (m)

- V = Wind speed (m/s)

Structural Engineering in Wind Turbine Design Projects

Tower Design Calculations

Tower design must account for various loads:

- Dead loads: Weight of components (typically 250-300 tons for a 2MW turbine)

- Live loads: Dynamic forces from operation

- Wind loads: Direct wind pressure and vortex shedding

The fundamental natural frequency calculation:

f = (1/2π) × √(k/m)

Where:

- f = Natural frequency (Hz)

- k = Tower stiffness (N/m)

- m = Effective mass (kg)

Foundation Engineering

Foundation design varies based on soil conditions:

Gravity foundations:

V = F × SF/γc

Where:

- V = Volume of concrete

- F = Overturning force

- SF = Safety factor (typically 1.5)

- γc = Concrete density

Control Systems Integration

SCADA Implementation

Modern wind turbine design projects incorporate sophisticated Supervisory Control and Data Acquisition (SCADA) systems that monitor:

- Wind speed and direction

- Power output

- Component temperatures

- Vibration levels

- Grid conditions

Pitch Control Mechanisms

Blade pitch control follows the equation:

θ = θ₀ + K × (ω – ω₀)

Where:

- θ = Pitch angle

- θ₀ = Initial pitch

- K = Control gain

- ω = Rotor speed

- ω₀ = Rated speed

Environmental Impact Assessment

Noise Analysis

Sound power level calculation:

SPL = 10 × log₁₀(P) + 50 + K₁

Where:

K₁ = Atmospheric absorption factor

Wake Effect Analysis

Wake losses can be estimated using the Jensen model:

V(x) = V₀[1 – (1-√(1-Ct))×(R/(R+kx))²]

Where:

- V(x) = Wind speed at distance x

- V₀ = Free stream velocity

- Ct = Thrust coefficient

- k = Wake decay constant

Economic Analysis and Optimization

Levelized Cost of Energy (LCOE)

LCOE calculation including detailed factors:

LCOE = (CAPEX + OPEX × PWF) / (AEP × (1-L) × n)

Where:

- CAPEX = Capital expenditure

- OPEX = Annual operating expenses

- PWF = Present worth factor

- AEP = Annual energy production

- L = Losses factor

- n = Project lifetime

Performance Optimization

Annual energy production calculation:

AEP = 8760 × P × CF × (1-L)

Where:

- 8760 = Hours per year

- P = Rated power

- CF = Capacity factor

- L = Total losses

Structural Analysis and Load Calculations

Wind turbine design projects must account for various loads and stresses. The tower, typically constructed from tubular steel sections, must withstand both static and dynamic loads. The fundamental natural frequency of the tower should avoid resonance with the rotor’s operational frequency. A simplified calculation for the natural frequency of a uniform tower is:

f = (1/2π) × √(k/m)

Where: f = Natural frequency (Hz) k = Tower stiffness (N/m) m = Effective mass (kg)

Site Selection and Wind Resource Assessment

The success of a wind turbine design project largely depends on proper site selection. Wind resource assessment typically requires at least 12 months of wind speed data collected at multiple heights. The wind shear profile can be modeled using the power law equation:

V₂ = V₁ × (h₂/h₁)ᵅ

Where:

- V₂ = Wind speed at height h₂

- V₁ = Wind speed at reference height h₁

- α = Wind shear exponent (typically 0.14 for neutral stability conditions)

Economic Considerations and Project Optimization

The financial viability of a wind turbine design project depends on optimizing the balance between power output and construction costs. The Levelized Cost of Energy (LCOE) serves as a crucial metric:

LCOE = (Total lifetime costs) / (Total lifetime energy production)

For a typical 2 MW turbine with a 20-year lifespan, assuming a capacity factor of 35%, the annual energy production would be:

AEP = 2,000 kW × 8,760 hours × 0.35 = 6,132,000 kWh

Future Trends in Wind Turbine Design Projects

The future of wind turbine design projects lies in innovative technologies like smart materials, advanced control systems, and improved aerodynamics. Developments in materials science are enabling longer blades with better performance characteristics. Digital twin technology is increasingly being incorporated into wind turbine design projects, allowing for real-time monitoring and predictive maintenance.

This comprehensive approach to wind turbine design projects demonstrates the complexity and interdisciplinary nature of modern renewable energy engineering. Success requires careful attention to aerodynamics, structural integrity, environmental impact, and economic viability. As technology continues to advance, wind turbine design projects will play an increasingly important role in the global transition to sustainable energy sources.

Worth Read Posts

- Wind Energy

- Smart Grid

- Wind Turbine Design With Example

- Wind Turbine Charge Controller

- Wind Turbine Capacity

- Wind Turbine Design Ideas

- Fading and Attenuation

- CR2032 vs CR2450

- CR2450N Battery

- CR2450 Battery Equivalent

Follow us on LinkedIn, “Electrical Insights,” to get the latest updates on Electrical Engineering.