Ultrasonic Sensors: A Comprehensive Guide

Ultrasonic sensors are devices that use ultrasonic waves, which are sound waves with frequencies higher than the audible range for humans (typically above 20,000 hertz), for various applications.

Table of Contents

These sensors operate on the principle of sending out ultrasonic waves and measuring the time it takes for the waves to bounce back after hitting an object. This information can then be used to determine the distance or presence of the object.

Ultrasonic Sensors Working Principle

The working principle of ultrasonic sensors is based on the transmission and reception of ultrasonic waves. Here’s a step-by-step explanation of how these sensors operate:

Generation of Ultrasonic Waves:

Ultrasonic sensors consist of a transducer, typically a piezoelectric crystal, that can convert electrical energy into ultrasonic waves. When an electrical voltage is applied to the crystal, it vibrates and generates ultrasonic waves in the frequency range beyond human hearing (typically above 20,000 hertz).

Wave Emission:

The ultrasonic sensor emits a short burst of ultrasonic waves into the surrounding environment. This burst of waves travels outward from the sensor.

Wave Propagation:

The ultrasonic waves move through the air until they encounter an object in their path. The waves continue to propagate until they hit a surface.

Reflection of Ultrasonic Waves:

When the ultrasonic waves strike an object, they are reflected back towards the sensor. The reflection occurs because the ultrasonic waves encounter a change in the medium (from air to the object’s surface), causing the waves to bounce back.

Reception of Reflected Waves:

The same transducer that emitted the ultrasonic waves now acts as a receiver. It detects the reflected waves returning from the object.

Time Measurement:

The sensor measures the time it takes for the ultrasonic waves to travel from the sensor to the object and back. This time measurement is crucial for determining the distance to the object.

Distance Calculation:

Using the known speed of sound in the air, which is approximately 343 meters per second (at room temperature), the sensor calculates the distance to the object. The formula for distance (D) is given by D = (Speed of Sound × Time) / 2.

Output Signal:

The calculated distance information is then processed by the sensor’s electronics, and the output is provided in a suitable format, often as an analog voltage, digital signal, or distance reading.

These sensors work by emitting ultrasonic waves, detecting their reflections from objects, measuring the time taken for the round trip, and using this time information to calculate the distance to the objects in their detection range. This working principle is fundamental to various applications, including distance measurement, object detection, and obstacle avoidance.

Ultrasonic Sensors Pins Configurations

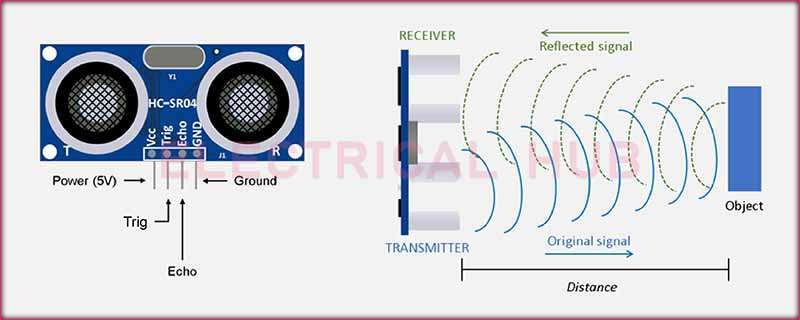

The pin configurations of ultrasonic sensors may vary depending on the specific model and manufacturer. However, We will discuss general overview of the typical pin configuration for a commonly used ultrasonic sensor module, like the HC-SR04. This module is widely used in hobbyist and educational projects.

The HC-SR04 ultrasonic sensor typically has four pins:

VCC (Voltage Supply):

This pin is used to provide power to the sensor. It typically requires a voltage in the range of 5V.

Trig (Trigger):

The Trig pin is used to trigger the start of the ultrasonic pulse. When a pulse of at least 10 microseconds is applied to this pin, the sensor emits an ultrasonic wave.

Echo:

The Echo pin is used to receive the ultrasonic waves that are reflected back from an object. The duration of the pulse received on this pin is proportional to the time it takes for the ultrasonic waves to travel to the object and back.

You May Want to Read

GND (Ground):

This pin is connected to the ground (0V) of the power supply.

Here is a basic representation of the pinout:

In use, you connect the VCC pin to the positive power supply, the GND pin to the ground, the Trig pin to a digital output pin on a microcontroller or other control system, and the Echo pin to a digital input pin. The time it takes for the pulse to travel and return is then measured by the microcontroller to calculate the distance to an object.

Types of Ultrasonic Sensors

Ultrasonic sensors come in various types, each designed for specific uses. Let’s break down some common ones:

Proximity Sensors (Single Transducer Sensors):

Designed for detecting objects in close range. Commonly used in automatic faucets, hand dryers, and paper towel dispensers in restrooms.

Distance Sensors (Dual Transducer Sensors):

Use two transducers where one emits ultrasonic waves, and the other receives them. Calculate distance by measuring the time waves take to travel to the target and back.

Ultrasonic Array Sensors

Arrays with multiple transducers in a specific pattern. Enable advanced sensing, such as determining the shape and orientation of objects.

Piezoelectric Sensors

Use piezoelectric crystals to generate ultrasonic waves. Crystals produce vibrations when an electric field is applied.

Resonant Sensors

Operate at a specific resonant frequency, providing high sensitivity and accuracy. Commonly used in precise applications like medical imaging.

Phased Array Sensors

Use an array of transducers controlled individually to focus and steer the ultrasonic beam electronically. Applied in industrial settings for non-destructive testing (NDT) and imaging.

Airborne Sensors

Designed to operate in the air. Used for measuring wind speed, detecting gas leaks, or monitoring airflow in industrial settings.

Underwater Sensors

Designed for underwater operation. Applied in underwater communication, navigation, and distance measurement in aquatic environments.

Doppler Ultrasonic Sensors (Doppler Sensors):

Use the Doppler effect to detect moving objects by measuring changes in frequency of reflected waves. Commonly used in motion detectors for security systems and automatic door openers.

Bulk Wave Sensors

Use bulk waves that travel through the material of an object. Suitable for applications like material thickness measurement and quality control in manufacturing.

SAW Ultrasonic Sensors (Surface Acoustic Wave Sensors):

Use surface acoustic waves to detect changes in frequency caused by the presence of an object. Applied in various applications, including pressure sensors and gas sensors.

Choosing the right ultrasonic sensor depends on specific application needs, such as detection range, accuracy, environmental conditions, and the type of material being measured or monitored.

Applications of Ultrasonic Sensors:

Car Parking Sensors:

Ever noticed your car beeping when you get close to something? That’s the ultrasonic sensor helping you avoid bumps during parking.

Automatic Soap Dispensers:

In public bathrooms, those soap dispensers that start when you put your hand under? Credit goes to these sensors for sensing your hand movement.

Robot Vacuums:

Those robotic vacuum cleaners that move around your house without hitting furniture? these sensors help them detect obstacles and navigate accordingly.

Security Motion Detectors:

Home security systems often use ultrasonic sensors in motion detectors, alerting you when there’s movement.

Medical Ultrasound Machines:

In the medical field, ultrasonic sensors are crucial for imaging devices like ultrasounds, helping doctors see inside the body.

Automatic Hand Dryers:

Hand dryers that start blowing air when you place your hands underneath? these sensors are responsible for detecting your hands.

Factory Robotics:

Robots in factories use these sensors to avoid collisions, making them aware of their surroundings.

Smart Home Devices:

Some smart home gadgets use ultrasonic sensors to detect your presence, like lights turning on when you enter a room.

DIY Tools:

DIY tools with ultrasonic sensors provide accurate distance measurements, making tasks like hanging a picture easier.

Underwater Communication:

Underwater devices use these sensors for communication and navigation, helping them operate below the water’s surface.

Advantages of Ultrasonic Sensors:

Non-Contact Measurement: These sensors operate without physical contact, allowing for non-invasive and non-destructive measurements, suitable for delicate materials and applications.

Versatility: Ultrasonic sensors are versatile, capable of measuring distances, detecting objects, and imaging in various environments, making them adaptable to diverse applications.

Reliability in Harsh Conditions: These sensors perform well in challenging conditions such as dusty or foggy environments, where other sensing technologies might struggle.

Disadvantages of Ultrasonic Sensors:

Limited Range and Resolution: In some applications, ultrasonic sensors may have limitations in terms of range and resolution, affecting their suitability for specific tasks.

Interference from Acoustic Noise: External acoustic noise can interfere with ultrasonic signals, potentially leading to inaccuracies in measurements.

Cost: High-precision sensors, especially those with advanced features, can be relatively expensive, impacting their adoption in cost-sensitive applications.

Ultrasonic sensors, with their ability to harness sound waves beyond our auditory range, have become integral to various industries and technological advancements. From enhancing the precision of robotics to enabling medical imaging breakthroughs, the adaptability and reliability of ultrasonic sensors continue to drive innovation.

As technology evolves, the development of more advanced ultrasonic sensors is expected, expanding their capabilities and applications across diverse fields.

What is an ultrasonic sensor?

An ultrasonic sensor is a device that uses ultrasonic waves (sound waves with frequencies higher than the human audible range) to measure distance, detect objects, or sense changes in the environment.

How do ultrasonic sensors work?

Ultrasonic sensors work by emitting ultrasonic waves and measuring the time it takes for these waves to bounce back after hitting an object. This information helps calculate the distance to the object or detect its presence.

Where are ultrasonic sensors commonly used?

Ultrasonic sensors have various applications, including distance measurement, obstacle avoidance in robotics, parking assistance in vehicles, level measurement in tanks, proximity sensing in automated systems, and medical imaging.

What is the range of detection for ultrasonic sensors?

The range of detection for ultrasonic sensors can vary, but it typically falls within a few centimeters to several meters, depending on the specific sensor and its application.

Are ultrasonic sensors affected by environmental conditions?

Yes, environmental factors such as temperature, humidity, and the type of material the ultrasonic waves encounter can affect sensor performance. Proper calibration and consideration of environmental conditions are essential.

Can ultrasonic sensors be used in outdoor applications?

Yes, ultrasonic sensors can be used outdoors, but their performance may be influenced by factors like wind and temperature. Some sensors are designed specifically for outdoor use and can handle these challenges.

Are ultrasonic sensors safe for humans and animals?

Yes, These sensors are generally considered safe for humans and animals because the ultrasonic waves they emit are at frequencies beyond the audible range. However, it’s essential to follow safety guidelines and specifications provided by the sensor manufacturer.

Can ultrasonic sensors work underwater?

Yes, there are ultrasonic sensors designed to operate underwater. They are used in applications such as underwater communication, navigation, and distance measurement in aquatic environments.

How do ultrasonic sensors differ from other types of distance sensors?

These sensors use sound waves to measure distance, while other types of distance sensors may use technologies like infrared (IR), laser, or lidar. Each technology has its advantages and is suitable for specific applications.

Are ultrasonic sensors difficult to install and calibrate?

These sensors are generally straightforward to install and calibrate. Most sensors come with user manuals that provide guidelines for proper installation and adjustment based on the specific application requirements.

Worth Read Posts

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.