Squirrel Cage Induction Motor: Working and Best Applications

Read More About

Introduction

A squirrel cage induction motor is one of the most commonly used types of induction motors. It derives its name from its rotor design, which resembles a squirrel cage wheel. Also known as a squirrel cage induction motor, it is widely employed in various industrial and commercial applications. This response will provide a detailed explanation of the squirrel cage rotor induction motor, including its construction, operation, advantages, and applications.

Construction of Squirrel Cage Induction Motor

Stator:

The stator of a squirrel cage induction motor consists of a laminated core with evenly spaced slots. These slots house the stator windings, which are typically made of copper or aluminum conductors. The stator winding is connected to a three-phase alternating current (AC) power supply, creating a rotating magnetic field when energized.

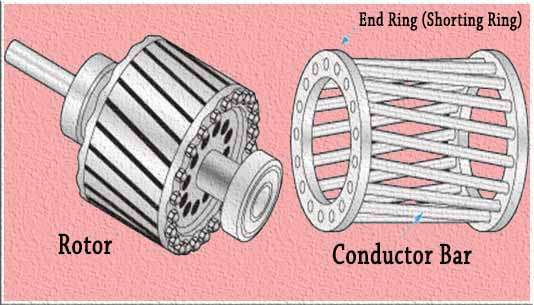

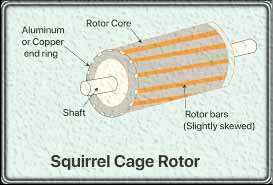

Rotor:

The rotor of a squirrel cage induction motor is composed of laminated iron cores stacked together. The iron cores are shorted at both ends by conducting bars or “squirrel cage” conductors, which are usually made of aluminum or copper. The conductors are arranged in a cylindrical shape around the rotor core and are connected by end rings. The rotor conductors resemble the bars of a squirrel cage, hence the name.

Operation of Squirrel Cage Induction Motor

Starting:

When the motor is initially powered, the rotating magnetic field produced by the stator winding induces voltage in the squirrel cage rotor conductors. This induced voltage causes currents to flow in the rotor bars, creating a magnetic field that interacts with the stator’s rotating magnetic field. The interaction generates torque, allowing the motor to start and accelerate.

Running:

Once the squirrel cage induction motor reaches its operating speed, the rotating magnetic field produced by the stator induces a voltage in the rotor conductors. This induced voltage generates rotor currents, creating a magnetic field that rotates at a speed slightly slower than the stator’s rotating magnetic field. The relative speed difference between the stator and rotor fields induces rotor currents, which in turn generate torque, enabling the motor to continue running.

Applications of squirrel cage rotor induction motor

Squirrel cage rotor induction motors are widely used in various industrial, commercial, and residential applications due to their advantages and versatility. Here are some common applications of squirrel cage rotor induction motors:

Industrial Machinery: Squirrel cage induction motors are extensively employed in industrial machinery, including pumps, compressors, fans, blowers, conveyors, mixers, and machine tools. They provide reliable and efficient operation for a wide range of industrial processes.

HVAC Systems: Squirrel cage induction motors are widely used in heating, ventilation, and air conditioning (HVAC) systems. They power air handling units, fans, and blowers, ensuring efficient and reliable airflow for cooling, heating, and ventilation in residential, commercial, and institutional buildings.

Refrigeration and Air Conditioning: Squirrel cage induction motors are utilized in refrigeration systems, such as refrigerators, freezers, and air conditioning units. They drive compressors, condenser fans, and evaporator fans, ensuring proper cooling and temperature control.

Water and Wastewater Treatment: Squirrel cage induction motors play a crucial role in water and wastewater treatment facilities. They power pumps, mixers, agitators, and aerators, assisting in processes such as water supply, filtration, disinfection, and wastewater treatment.

Manufacturing Industry: In the manufacturing sector, squirrel cage induction motors find applications in various processes, including conveyor systems, material handling equipment, packaging machinery, and assembly line operations. Their reliability and cost-effectiveness make them a popular choice in manufacturing facilities.

Agricultural Equipment: Squirrel cage induction motors are used in agricultural applications, powering machinery such as irrigation pumps, grain conveyors, feed mixers, and ventilation systems in livestock farming.

Residential Appliances: Squirrel cage induction motors are found in various household appliances, including washing machines, dryers, dishwashers, vacuum cleaners, and kitchen appliances. Their efficient and reliable operation ensures the functionality of these everyday appliances.

Automotive Industry: Squirrel cage induction motors are employed in automotive applications, particularly in electric vehicles (EVs) and hybrid vehicles. They power systems such as electric power steering, electric braking, and electric drivetrains, contributing to the shift towards cleaner and more energy-efficient transportation.

Renewable Energy Systems: Squirrel cage induction motors are used in renewable energy systems, such as wind turbines and hydroelectric power plants. They convert the mechanical energy from wind or water into electrical energy, contributing to the generation of clean and sustainable power.

Commercial and Institutional Buildings: Squirrel cage induction motors are used in commercial and institutional buildings for various applications, including escalators, elevators, pumps, fans, and ventilation systems. They ensure smooth and reliable operation of these building systems.

These applications demonstrate the wide-ranging utility of squirrel cage rotor induction motors across multiple industries and sectors. Their reliability, cost-effectiveness, efficiency, and compatibility with standard electrical systems make them a popular choice for numerous motor-driven applications.

advantages of squirrel cage rotor induction motor

Squirrel cage rotor induction motors offer several advantages that contribute to their widespread use in various applications. Here are some of the key advantages:

Simple and Robust Construction: Squirrel cage induction motors have a simple design with a rotor consisting of shorted bars, which eliminates the need for slip rings and brushes. This simplicity makes them mechanically robust and less prone to failure. The absence of these additional components also reduces maintenance requirements and associated costs.

High Reliability: Due to their simple construction and absence of wear-prone components, squirrel cage induction motors are highly reliable. They can operate continuously for long periods without significant maintenance or performance issues. This reliability is crucial for applications where downtime and maintenance disruptions are undesirable.

Cost-Effective: Squirrel cage induction motors are cost-effective in terms of both initial purchase cost and long-term operation. Their simple construction, standardized design, and high production volumes contribute to their affordability. Additionally, the absence of slip rings and brushes reduces maintenance costs and eliminates the need for periodic replacement, further lowering operating expenses.

High Efficiency: Squirrel cage induction motors offer high efficiency, especially at full load operating conditions. They have optimized designs with minimal losses, resulting in efficient conversion of electrical energy into mechanical work. Higher efficiency means reduced energy consumption, resulting in energy savings and lower operating costs over the motor’s lifespan.

Wide Range of Power Ratings: Squirrel cage induction motors are available in a wide range of power ratings, from small fractional horsepower motors to several megawatts. This versatility allows them to be used in various applications, from small appliances to heavy industrial machinery.

Maintenance-Free Operation: The absence of slip rings and brushes in squirrel cage induction motors eliminates the need for regular maintenance associated with these components. This feature makes them suitable for applications where maintenance accessibility is challenging or frequent servicing is undesirable.

High Torque-to-Inertia Ratio: Squirrel cage induction motors typically have a high torque-to-inertia ratio, which means they can quickly accelerate and decelerate loads efficiently. This characteristic is particularly advantageous in applications where frequent starting, stopping, or reversing is required.

Wide Operating Range: Squirrel cage induction motors can operate over a wide range of speeds and loads. They exhibit stable performance even under varying conditions, making them suitable for applications where the motor needs to adapt to changing operational requirements.

Noise and Vibration Control: Squirrel cage induction motors generally operate with low noise and vibration levels. The balanced design of the rotor bars and stator windings minimizes unwanted vibrations, ensuring smooth and quiet motor operation.

Easy Integration: Squirrel cage induction motors are compatible with standard electrical power systems and control equipment. They can be easily integrated into existing installations without the need for specialized components or complex control systems.

Overall, squirrel cage rotor induction motors provide a combination of reliability, cost-effectiveness, efficiency, and versatility, making them a popular choice for a wide range of applications in industries ranging from residential and commercial to industrial and automotive.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us LinkedIn to see our latest posts.

Frequently Asked Questions

What is a squirrel cage rotor induction motor?

A squirrel cage rotor induction motor is an AC electric motor that consists of a stationary stator and a rotating rotor. The rotor has conductive bars (resembling a squirrel cage) shorted at both ends, which provide the motor’s unique characteristics.

How does a squirrel cage rotor induction motor work?

When an AC voltage is applied to the stator windings, it creates a rotating magnetic field. This magnetic field induces currents in the rotor bars due to the principle of electromagnetic induction. The interaction between the rotating magnetic field and the induced currents in the rotor bars causes the rotor to rotate, generating mechanical power.

When an AC voltage is applied to the stator windings, it creates a rotating magnetic field. This magnetic field induces currents in the rotor bars due to the principle of electromagnetic induction. The interaction between the rotating magnetic field and the induced currents in the rotor bars causes the rotor to rotate, generating mechanical power.

What are the advantages of squirrel cage rotor induction motors?

Some advantages of squirrel cage rotor induction motors include: simplicity of construction, high reliability, low maintenance requirements, ability to operate in harsh environments, good torque characteristics, and cost-effectiveness.

What are the disadvantages of squirrel cage rotor induction motors?

Some disadvantages of squirrel cage rotor induction motors are: limited speed control compared to other motor types, lower efficiency at light loads, lower starting torque compared to other motor types (which may require external starting mechanisms in some cases), and the inability to provide regenerative braking.

How are squirrel cage rotor induction motors started?

Can squirrel cage rotor induction motors be used with variable speed drives?

Yes, squirrel cage rotor induction motors can be used with variable frequency drives (VFDs) to achieve variable speed control. By varying the frequency and voltage supplied to the motor, the speed and torque characteristics can be adjusted according to the application requirements.

Are squirrel cage rotor induction motors efficient?

Squirrel cage rotor induction motors can achieve relatively high efficiency, especially at full load. However, their efficiency may decrease at light loads compared to other motor types, such as permanent magnet motors or synchronous motors.

Can squirrel cage rotor induction motors be used in hazardous environments?

Yes, squirrel cage rotor induction motors can be designed for hazardous environments by incorporating appropriate protection measures, such as explosion-proof enclosures or special coatings, to meet the requirements of the specific hazardous location.

How do squirrel cage rotor induction motors differ from wound rotor induction motors?

The main difference between squirrel cage rotor induction motors and wound rotor induction motors lies in the construction of the rotor. In squirrel cage motors, the rotor bars are permanently shorted, while in wound rotor motors, the rotor windings are externally connected to resistors or other external devices, allowing for improved speed control and higher starting torque.

Can squirrel cage rotor induction motors be used in single-phase applications?

Squirrel cage rotor induction motors are primarily designed for three-phase power systems. However, special designs and techniques exist to adapt induction motors for single-phase applications, although they may have limitations in terms of power and efficiency compared to three-phase motors.