Plant Factor, Plant Capacity Factor, and Load Factor: Important Examples

Plant Factor is a key performance metric for power plants, which compares the actual amount of electricity generated to the maximum amount that might be produced under perfect circumstances. It offers perceptions of the dependability and operational efficiency of power-producing plants.

In order to evaluate a plant’s economic feasibility, schedule maintenance, and make well-informed judgments about power generation, power plant operators, investors, and policymakers need to know the Plant Factor. We will discuss the idea of the Plant Factor, its calculation, and three different kinds of power plants with determined Plant Factors in this comprehensive presentation.

Table of Contents

Table of Contents

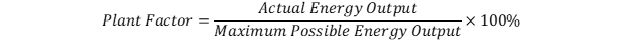

Plant Factor Formula

The Plant Factor is calculated using the following formula:

Where:

Actual Energy Output: The actual electricity generated by the power plant over a specified period (usually a year).

Maximum Possible Energy Output: The electricity the plant could produce under ideal, continuous operation over the same period.

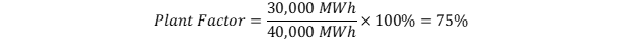

Example of a Hydroelectric Power Plant

Let’s consider a hydroelectric power plant. In a year, it generated 30,000 MWh (megawatt-hours) of electricity. The maximum potential output, based on water availability and plant design, is 40,000 MWh. Using the Plant Factor formula:

The Plant Factor for the hydroelectric power plant is 75%.

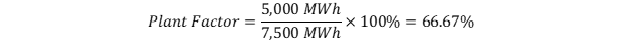

Example of a Solar Photovoltaic (PV) Power Plant

A solar PV power plant produced 5,000 MWh of electricity during the year, while its maximum potential output, based on the available sunlight, was 7,500 MWh. Using the Plant Factor formula:

The Plant Factor for the solar PV power plant is approximately 66.67%.

Example of a Natural Gas Combined Cycle Power Plant

A natural gas combined cycle power plant generated 80,000 MWh of electricity in a year, and its maximum potential output, based on fuel availability and operational efficiency, is 100,000 MWh. Using the Plant Factor formula:

The Plant Factor for the natural gas combined cycle power plant is 80%.

These examples demonstrate how the Plant Factor reflects the efficiency and reliability of different types of power plants. It serves as a valuable metric for assessing the performance of a facility and can guide decisions related to maintenance, capacity planning, and energy economics.

What do you mean by plant capacity factor?

A power plant’s efficiency over a given time period, often a year, is measured by the Plant Capacity Factor, also called the Capacity Factor. It is the ratio of the actual energy produced by the power plant to the maximum energy it could produce if it ran continuously at its rated capacity for the same amount of time. It is given as a percentage.

Essentially, it provides information about how near a power plant is to reach its maximum output, as well as operating efficiency and utilization. Whereas a low capacity factor could point to sporadic operation, maintenance downtime, or underutilization of the plant’s capacity, a high capacity factor indicates that the plant is functioning effectively and consistently.

Example of Wind Turbine Farm

Let’s consider a wind turbine farm with a total rated capacity of 100 megawatts (MW). Over a year, it generated 30,000 megawatt-hours (MWh) of electricity. To calculate the Plant Capacity Factor:

Actual Energy Output = 30,000 MWh

Maximum Possible Energy Output (based on rated capacity) = 100 MW * 8,760 hours = 876,000 MWh

Now, calculate the Plant Capacity Factor:

The Plant Capacity Factor for the wind turbine farm is approximately 3.42%.

Example of a Nuclear Power Plant

Consider a nuclear power plant with a total rated capacity of 1,000 MW. In a year, it generated 8,760,000 MWh of electricity. Calculate the Plant Capacity Factor:

Actual Energy Output = 8,760,000 MWh

Maximum Possible Energy Output (based on rated capacity) = 1,000 MW * 8,760

= 8,760,000 MWh

Now, calculate the Plant Capacity Factor:

The Plant Capacity Factor for the nuclear power plant is 100%.

In these examples, the wind turbine farm has a low Plant Capacity Factor of 3.42% due to the intermittent nature of wind energy, while the nuclear power plant operates at a high capacity factor of 100% because it runs consistently and close to its rated capacity throughout the year.

What do you mean by plant load factor?

PLF, or plant load factor, is a crucial performance indicator for power plants. It shows the relationship between the actual amount of energy produced by a power plant over a given time period (often a year) and the maximum amount of electricity it could produce if it ran continuously at its rated capacity over that same time.

PLF, which can be stated as a percentage, shows how well a power plant is used. A low PLF could be the consequence of underutilization, downtime, or irregular operation, whereas a high PLF denotes efficient and constant functioning.

Example of a Coal-Fired Power Plant

Consider a coal-fired power plant with a total rated capacity of 500 megawatts (MW). Over a year, it generated 1,800,000 megawatt-hours (MWh) of electricity. To calculate the Plant Load Factor:

Actual Energy Output = 1,800,000 MWh

Maximum Possible Energy Output (based on rated capacity) = 500 MW * 8,760 hours = 4,380,000 MWh

Now, calculate the Plant Load Factor:

The Plant Load Factor for the coal-fired power plant is approximately 41.10%.

Example of a Solar Photovoltaic (PV) Power Plant

Let’s consider a solar PV power plant with a total rated capacity of 10 MW. Over the year, it generated 7,000 MWh of electricity. To calculate the Plant Load Factor:

Actual Energy Output = 7,000 MWh

Maximum Possible Energy Output (based on rated capacity) = 10 MW * 8,760 hours = 87,600 MWh

Now, calculate the Plant Load Factor:

The Plant Load Factor for the solar PV power plant is approximately 7.99%.

In these examples, the coal-fired power plant has a PLF of 41.10%, indicating moderate utilization, while the solar PV power plant has a lower PLF of 7.99% due to its intermittent generation, which depends on sunlight availability. The PLF helps evaluate the efficiency and consistent operation of different types of power plants.

Difference between plant factor, capacity factor, and load factor

In the context of power generation and performance assessment, three similar but different terminology are used: plant factor, capacity factor, and load factor. The following are the main variations between them:

Plant Factor:

Definition: The plant factor, also known as the capacity factor, calculates the difference between the amount of electricity a power plant actually produces over a certain time period and the maximum amount it could create if it ran continuously at its rated capacity during that same time. It has a percentage as its expression.

Purpose: Plant Factor evaluates how efficiently a power plant utilizes its full capacity for electricity generation.

Capacity Factor:

Definition: Plant Factor and capacity factor are interchangeable terms that quantify the same idea. It shows the percentage between the amount of power produced as it is and the amount that could be produced if the plant ran constantly at its rated capacity. A percentage is another way to express the capacity factor.

Purpose: The capacity Factor serves the same purpose as the Plant Factor, indicating the operational efficiency of a power plant.

Load Factor:

Definition: The ratio of a power plant’s average demand or load during a certain time period to its rated capacity is called the load factor. It has the same percentage expression as the other factors.

Purpose: The Load Factor is the measure of how well a power plant generates electricity in relation to the actual load that it is serving. In order to maximize resource allocation and efficiency, utilities and grid operators frequently use it to reflect the alignment of generation and demand.

In conclusion, the Load Factor highlights the connection between a power plant’s capacity and real electricity demand, whilst the Plant Factor and Capacity Factor refer to a power plant’s efficiency in producing electricity relative to its maximum capacity. In the business, the words “plant factor” and “capacity factor,” which are practically the same metrics, are frequently used interchangeably.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts