IGBT Rectifier: Working, Features and Important Applications

An IGBT rectifier, also known as an “Insulated Gate Bipolar Transistor rectifier,” is a kind of rectification circuit that uses IGBTs to change direct current (DC) from alternating current (AC). IGBT rectifiers are widely used in many different applications, especially in power systems and industries where accurate control of DC voltage and current is crucial.

We shall examine the IGBT rectifier’s operation, special features, and uses in this comprehensive description.

Table of Contents

IGBT Rectifier: Working Principle

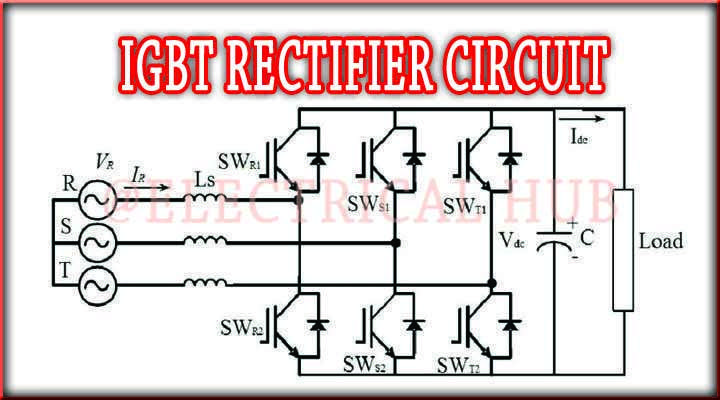

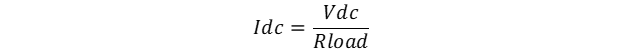

Rectification is the process of converting AC electricity to DC, and it is the basis for how the IGBT rectifier works. An IGBT rectifier’s main parts include diodes, transformers, control circuits, and IGBTs. This is a detailed explanation of how an IGBT rectifier operates:

AC to DC Conversion: The mains provide AC electricity to the IGBT rectifier first. Usually, the AC voltage input is sinusoidal.

Stage of Rectification: To create a pulsing DC voltage, the AC voltage is first rectified using diodes. Unidirectional current is produced by diodes, which only permit one direction of current flow.

Stage of Filtering: Next, the pulsating DC voltage is sent through a filter, which is often made up of inductors and capacitors. By decreasing ripple and smoothing the voltage waveform, this stage produces a DC voltage that is comparatively constant.

IGBT Control: The IGBTs are then supplied with the filtered DC voltage. The output voltage and current are managed by the IGBTs. The rectifier precisely adjusts the output voltage and current in accordance with the requirements of the load by adjusting the duty cycle and switching frequency of the IGBTs.

Feedback Control: Constantly monitoring the output, feedback mechanisms—such as voltage and current sensors—provide data to the control circuitry. Based on the feedback, the control system modifies the IGBT switching to provide a steady and precise DC output.

Output: The ultimate result is a DC voltage that is well-regulated and has little ripple or harmonic distortion, making it appropriate for a variety of uses.

Components and Equations for IGBT Rectifier

The basic components of an IGBT rectifier include:

IGBTs: Insulated Gate Bipolar Transistors

Diodes: Used for freewheeling and rectification

DC Bus Capacitor: Smoothens the output voltage

The primary working equations involve the voltage and current relationships, as well as the control scheme. Below, we will explain the operation and provide some key equations:

AC Voltage Input (Vin): This is the voltage supplied by the AC source. It is typically sinusoidal.

AC Current (Iin): The current drawn from the AC source, which is determined by the load.

Rectified DC Voltage (Vdc): The DC voltage across the DC bus. It is the result of rectifying the AC input.

DC Current (IDC): The DC current flowing through the load.

IGBT and Diode Conduction: he IGBTs conduct during a specific interval to control the voltage across the DC bus. IGBT conduction can be controlled using pulse-width modulation (PWM).

Diodes conduct when IGBTs are off or during freewheeling to allow the flow of current in a single direction.

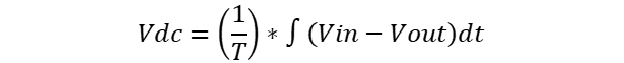

Rectification Equation: The rectified DC voltage (Vdc) can be calculated as an average value of the rectified voltage using the following equation:

Where:

- T is the time period.

- Vin is the input AC voltage.

- Vout is the output voltage.

DC Current Equation: The DC current (IDC) is related to the DC voltage (Vdc) and the load as per Ohm’s law:

Where:

- Rload is the load resistance.

Control Scheme: The control scheme for IGBT rectifiers can vary, but often it involves pulse-width modulation (PWM) to control the conduction of IGBTs and, therefore, the output voltage. The duty cycle of the PWM signal is adjusted to control the average DC output voltage.

Power Factor Correction (PFC): In some IGBT rectifiers, additional control is used for power factor correction to improve the input power factor. This is typically achieved using boost converters and control algorithms to minimize harmonic distortion.

How does IGBT control voltage?

By altering the gate-to-emitter voltage (VGE), IGBT regulates the voltage. An electric field is produced at the gate terminal (G) in response to an applied voltage. This electric field regulates the current flow between the emitter (E) and collector (C), hence controlling the output voltage.

Why is IGBT used in rectifiers?

Rectifiers employ IGBTs for the following main purposes:

High Voltage Handling: In rectification applications, IGBTs are able to manage high voltage levels.

High Current Capability: As a need for power-hungry applications, they are able to manage high current levels.

Precise Control: IGBTs provide steady DC output by providing precise control over current conduction.

Efficiency: IGBTs minimize power losses due to their low on-state voltage drop.

Harmonic Distortion: For clean output power, they can lower harmonic distortion.

Quick Switching: IGBTs’ quick switching reduces switching losses and enhances control.

Low EMI Interference: Low electromagnetic interference (EMI) is a result of their fast switching.

Parallel Operation: For greater power, several IGBTs can be utilized in parallel.

Ruggedness: They are dependable and strong, making them perfect for hostile settings.

Protection: IGBT modules frequently come with built-in security measures.

Because of its high voltage and current capabilities, exact control, efficiency, reduced harmonic distortion, quick switching, low EMI, parallel operation, durability, and protective features, IGBTs are employed in rectifiers and are suited for various power conversion applications.

IGBT Rectifier: Unique Features

Great Efficiency: Because of the low on-state voltage drop of IGBTs, IGBT rectifiers are renowned for their great efficiency. As a result, power conversion efficiency is improved overall and power losses are decreased.

Accurate Control: IGBTs provide accurate control over the output current and voltage. The rectifier can modify the switching frequency and pulse-width modulation (PWM) to customize the output to match particular load demands.

Low Harmonic Distortion: IGBT rectifiers can meet power quality requirements by lowering harmonic distortion in the output. This is essential for applications that need a steady and clean DC supply.

Regenerative Braking: In some situations, IGBT rectifiers can be utilized to recover and transform kinetic energy into electrical energy in industrial systems and electric cars.

Minimal Electro-Magnetic Interference (EMI): IGBT rectifiers are a good fit for applications that are susceptible to electromagnetic interference because of their quick switching speeds.

Parallel Operation: To satisfy increased power demands without sacrificing dependability, multiple IGBT rectifier units can be connected in parallel.

What is the difference between an SCR and an IGBT rectifier?

Power conversion applications employ both SCR (Silicon Controlled Rectifier) and IGBT (Insulated Gate Bipolar Transistor) rectifiers; nevertheless, there are notable distinctions between them with respect to features, functions, and applications. The two are contrasted as follows:

Principle of Operation:

SCR Rectifier: An SCR is a unidirectional device, meaning that it can only permit one direction of current flow. It functions as a switch that can be activated to conduct; once activated, it cannot be deactivated until the current falls below a predetermined threshold. SCR rectifiers are usually utilized in battery charging applications or other situations where unidirectional current flow is enough.

IGBT Rectifier: An IGBT is a bidirectional device that has the ability to regulate both directions of current flow. It functions as an on-and-off switch to give you exact control over the output voltage and current. IGBT rectifiers are utilized in regenerative braking and motor drives, among other applications where bidirectional current regulation is necessary.

Control and Regulation:

SCR Rectifier: SCR rectifiers are renowned for their ease of use, although they do not have the exact control that IGBTs do. SCRs are limited in their ability to be controlled since once activated, they stay on until the AC current spontaneously changes direction.

IGBT Rectifier: By using methods like feedback control loops and pulse-width modulation (PWM), IGBT rectifiers provide exact control over the output voltage and current. They are appropriate for a variety of applications due to their ability to produce DC output that is both stable and regulated.

Efficiency:

SCR Rectifier: SCRs lose more power during conduction because of their comparatively large on-state voltage drop. When compared to IGBT rectifiers, this may lead to a reduction in total efficiency.

IGBT Rectifier: IGBTs are more efficient and have fewer power losses due to their lower on-state voltage drop. Their energy-efficient operation is well-known.

Applications:

SCR Rectifier: SCRs are frequently utilized in electroplating, battery chargers, and some welding equipment where unidirectional current regulation is adequate.

IGBT Rectifier: IGBT rectifiers are used in power converters for renewable energy sources, regenerative braking, electric vehicle charging, industrial drives, and other applications where accurate bidirectional current control is required.

Harmonic Distortion:

SCR Rectifier: Higher output current harmonic distortion from SCRs may have an impact on power quality.

IGBT Rectifier: IGBT rectifiers are appropriate for applications needing clean, reliable DC power because they can be made to eliminate harmonic distortion.

IGBT Rectifier: Applications

Industrial drives: IGBT rectifiers are frequently found in electric motor variable speed drives, providing exact control over motor efficiency and speed.

Battery Charging: IGBT rectifiers are used to supply a regulated charging current to batteries in battery charging systems for electric vehicles and uninterruptible power supplies (UPS).

Electroplating: In order to provide steady DC power for the deposition of metal coatings, IGBT rectifiers are used in electroplating procedures.

Electrolysis: IGBT rectifiers are used in industries that use electrolysis, such as metal refining and water treatment, to regulate the electrochemical processes.

Welding: IGBT rectifiers in welding equipment supply steady, regulated DC power for a range of welding operations.

Renewable Energy: Inverters for wind and solar power, which convert the generated AC power, depend heavily on IGBT rectifiers.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts