Ultrasonic Motor Accuracy: A Comprehensive Overview

Ultrasonic motor accuracy is a defining feature of these unique electromechanical devices, setting them apart from many traditional motor types. Ultrasonic motors are renowned for their exceptional precision and reliability, making them highly sought after in applications where exact positioning and controlled motion are critical.

Table of Contents

Piezoelectric Precision

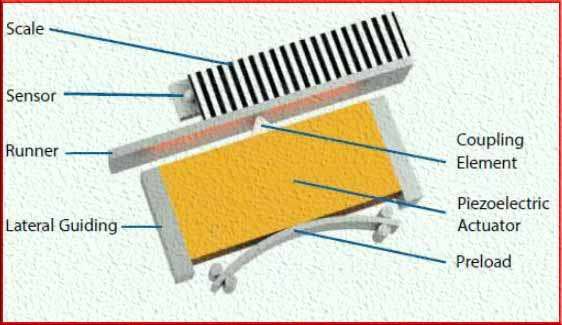

At the heart of ultrasonic motor accuracy lies the piezoelectric effect, a phenomenon in which certain materials, like piezoceramic crystals, deform when subjected to electrical voltage changes.

In the case of ultrasonic motors, this effect is harnessed to generate ultrasonic vibrations. These vibrations are incredibly consistent and can operate at frequencies ranging from tens of kilohertz to megahertz. This precision in vibration generation forms the basis of ultrasonic motor accuracy.

High Resolution and Fine Control

Ultrasonic motors excel in providing high-resolution motion and fine control. Their ability to generate small, incremental movements with exceptional repeatability makes them ideal for applications demanding precise positioning.

Whether it’s adjusting the focus in a camera lens, manipulating surgical instruments in medical robotics, or aligning optical components in advanced microscopy, ultrasonic motors can achieve sub-micron levels of accuracy.

Contact and Non-Contact Types

Ultrasonic motors come in both contact and non-contact variants, and their accuracy can vary based on the design. Contact-type ultrasonic motors rely on the friction between the vibrating element and a rotor to produce motion. While they offer excellent accuracy, they may be more susceptible to wear and tear over time, potentially affecting long-term accuracy.

Non-contact ultrasonic motors, on the other hand, operate by generating standing waves or traveling waves to create motion without physical contact. This type of motor often exhibits high levels of accuracy while minimizing wear and maintaining long-term reliability.

Low Hysteresis and Backlash

Ultrasonic motors exhibit minimal hysteresis and backlash, which are common issues in many traditional motors. Hysteresis refers to the lag between the input signal and the motor’s response, while backlash is the play or free movement when the direction of motion is reversed. Ultrasonic motors significantly reduce or eliminate these issues, ensuring that the motor responds precisely to input commands without delays or unintended movements.

Applications Requiring Ultrasonic Motor Accuracy

Ultrasonic motor accuracy finds applications across various industries, including:

Semiconductor Manufacturing: In semiconductor fabrication, ultrasonic motors are used for wafer handling and positioning, where sub-micron accuracy is essential for precise chip production.

Medical Robotics: Ultrasonic motors are employed in robotic surgical instruments to perform delicate surgeries with utmost precision, ensuring minimal invasiveness and reduced risk to patients.

Optical Systems: Ultrasonic motors are integral to high-resolution optical systems, such as microscopes and telescopes, where they enable precise positioning of lenses, mirrors, and other optical components for clear imaging.

Aerospace and Defense: In this sector, ultrasonic motors are used for camera gimbals, antenna positioning, and flight control systems, contributing to accuracy in surveillance and navigation.

Industrial Automation: Ultrasonic motor accuracy enhances the efficiency of automation systems by providing precise motion control in tasks like material handling, packaging, and conveyor belt systems.

Micro/Nano Manipulation: Researchers and engineers utilize ultrasonic motors for manipulating micro and nano-sized objects in fields like nanotechnology and MEMS.

In conclusion, ultrasonic motor accuracy is a key attribute that makes these motors indispensable in applications requiring precise positioning and controlled motion. Their ability to deliver high-resolution, low hysteresis, and minimal backlash motion ensures that they continue to play a vital role in advancing technology in various industries, where precision and reliability are paramount.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

- Ultrasonic Motor: A Comprehensive Overview

- Servo Motors: High-Precision Control in Modern Technology

- Arduino Stepper Motor Projects: A Quick Guide

- Induction Motor: Important Types, Construction & Working

- Wound Rotor Induction Motor: Working & Important Applications

- Squirrel Cage Induction Motor: Working and Best Applications

- Brushless Motor(BLDC): Construction, Types & Applications

- Stepper Motor Position Control with Arduino: A Quick Guide