Top 70 Synchronous Motor Interview Questions: Best Overview

In electrical engineering, interviews for roles related to synchronous motors often delve deep into the technical aspects and operational principles of these crucial devices. Aspiring candidates preparing for such interviews encounter a spectrum of Synchronous Motor Interview Questions, designed to assess their comprehension, problem-solving skills, and practical knowledge in this specialized field.

The interview process for roles concerning synchronous motors demands a comprehensive understanding of their functioning, applications, and intricacies, making it imperative for candidates to equip themselves with a robust grasp of related concepts and methodologies.

Synchronous Motor Interview Questions

The dynamics of Synchronous Motor Interview Questions are multifaceted, covering a broad array of topics pivotal to the understanding of these motors.

From inquiries about the fundamental principles governing their operation to the nuanced intricacies of synchronous motor control systems, candidates are presented with challenges aimed at evaluating their expertise and proficiency in handling diverse scenarios related to these machines.

Synchronous Motor Interview Questions, often interwoven with queries about their construction, synchronous speed determinants, and synchronization methods, compel candidates to showcase their grasp of theoretical frameworks alongside practical problem-solving abilities in this domain. Hence, acing these questions necessitates a holistic understanding of synchronous motors, from their theoretical underpinnings to real-world applications.

1. What is a synchronous motor, and how does it differ from other types?

A synchronous motor is an AC motor that operates at a constant speed determined by the frequency of the power supply and the number of poles. Unlike induction motors, synchronous motors run at synchronous speed without slip.

2. What are the primary applications of synchronous motors?

Synchronous motors find use in various applications such as power generation, industrial drives, synchronous condensers in power factor correction, and precision motion control systems.

3. How does a synchronous motor maintain synchronism with the power supply?

Synchronous motors maintain synchronism because the rotor rotates at the same speed as the rotating magnetic field generated by the stator.

4. What factors determine the speed of a synchronous motor?

The speed of a synchronous motor is directly related to the frequency of the power supply and inversely related to the number of poles in the motor.

5. Can synchronous motors handle variable loads efficiently?

Synchronous motors are less efficient in handling variable loads compared to induction motors due to their fixed synchronous speed characteristics.

6. What happens if a synchronous motor loses synchronism?

If a synchronous motor loses synchronism with the power supply, it ceases to operate efficiently and might require re-synchronization to restart.

7. How are synchronous motors started?

Synchronous motors typically require auxiliary devices like damper windings or starting motors to bring them up to synchronous speed before synchronizing with the power supply.

8. What are the advantages of using synchronous motors over induction motors?

Synchronous motors offer better power factor correction, higher efficiency under constant load, and precision speed control compared to induction motors.

9. Can synchronous motors operate at variable speeds without modifications?

Synchronous motors require external control systems like variable frequency drives (VFDs) to operate at variable speeds effectively.

10. What are the main components of a synchronous motor?

A synchronous motor consists of a stator, rotor, excitation system, and in some cases, a damper winding or starting mechanism.

11. How does the excitation system work in a synchronous motor?

The excitation system supplies direct current to the rotor windings, creating a magnetic field. This field synchronizes with the stator’s rotating magnetic field, enabling the motor to run at synchronous speed.

12. Can synchronous motors operate without an excitation system?

No, synchronous motors rely on the excitation system to generate the magnetic field necessary for synchronism with the stator field.

13. What are the different types of excitation systems used in synchronous motors?

There are mainly two types: DC excitation systems, where DC power supplies the rotor, and permanent magnet excitation systems, utilizing permanent magnets in the rotor to generate the magnetic field.

14. How is the power factor controlled in synchronous motors?

Synchronous motors have the ability to adjust their power factor by varying the excitation current. By adjusting this excitation, the motor can improve or correct the power factor.

15. What role does the damper winding play in synchronous motors?

The damper winding helps the motor to start by providing a slight initial slip before reaching synchronous speed. It also helps the motor maintain stability during sudden load changes.

16. Can synchronous motors be used in applications requiring high torque at low speeds?

Synchronous motors typically operate at synchronous speed and might not be the primary choice for applications requiring high torque at low speeds without additional gearing or modifications.

17. How are synchronous motors controlled for speed regulation?

Speed regulation in synchronous motors often involves controlling the excitation or adjusting the frequency of the power supply using variable frequency drives (VFDs).

18. What are the key differences between synchronous reluctance motors and traditional synchronous motors?

Synchronous reluctance motors have a simpler rotor structure without windings or magnets, relying on the reluctance torque principle. They offer potentially higher efficiency and simpler construction compared to traditional synchronous motors.

19. Can synchronous motors generate power when mechanically driven?

Synchronous motors operating above synchronous speed can function as generators, converting mechanical energy into electrical energy due to their ability to maintain synchronism with the power supply.

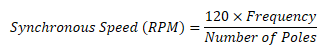

20. How do you calculate the synchronous speed of a synchronous motor?

The formula for synchronous speed in RPM is

21. How do you determine the number of poles in a synchronous motor?

The number of poles in a synchronous motor is determined by the design and construction of the motor. It is a fixed characteristic specified by the manufacturer.

22. What are the typical applications that benefit from the high efficiency of synchronous motors?

Synchronous motors are preferred in applications demanding constant speed and high efficiency, such as in industrial pumps, compressors, fans, and certain types of industrial machinery.

23. How does the load angle affect the operation of a synchronous motor?

The load angle refers to the angular difference between the stator’s magnetic field and the rotor’s magnetic field. Proper load angle adjustment is crucial for the motor to operate efficiently and maintain synchronism.

24. Can synchronous motors operate in both motoring and generating modes simultaneously?

Yes, in certain scenarios, synchronous motors can operate in motoring mode while simultaneously supplying electrical power to the grid as generators, known as synchronous condensers.

25. What measures are taken to mitigate hunting or instability issues in synchronous motors?

Various control systems and stabilizing methods, including automatic voltage regulators (AVRs) and power system stabilizers (PSSs), are employed to prevent hunting or instability in synchronous motors.

26. How does the excitation control system affect the efficiency and performance of a synchronous motor?

Optimizing the excitation control system helps regulate the motor’s power factor and influences its efficiency, stability, and response to varying loads.

27. What are the key considerations when selecting a synchronous motor for a specific application?

Factors such as the required speed, torque characteristics, power factor requirements, efficiency, and the ability to control the motor’s operation play crucial roles in selecting the appropriate synchronous motor.

28. How do you measure the power factor of a synchronous motor, and why is it important?

Power factor in a synchronous motor can be measured using power analyzers or meters. It’s a critical parameter indicating the motor’s efficiency in converting electrical power into useful work.

29. Can synchronous motors operate in parallel with other synchronous motors or power sources?

Synchronous motors can operate in parallel with other synchronous motors or power sources when synchronized to the same frequency and phase.

30. What are the primary challenges in maintaining the synchronism of synchronous motors?

Maintaining synchronism involves addressing issues such as load changes, transient conditions, and the proper control of the excitation system to prevent loss of synchronism.

31. How does the construction and material selection of the rotor impact the performance of a synchronous motor?

Rotor construction and material affect the motor’s inertia, ability to withstand mechanical stresses, and efficiency. Materials with high magnetic permeability are often used to optimize performance.

32. What are the advantages of using permanent magnet rotors in synchronous motors?

Permanent magnet rotors offer higher efficiency, power density, and potentially lower losses compared to conventional rotor designs, enhancing motor performance.

33. How does the starting mechanism in a synchronous motor differ from induction motors?

Synchronous motors typically require external assistance like damper windings, starting motors, or additional mechanisms to bring them to synchronous speed before connecting to the power supply, unlike induction motors that self-start.

34. What are the characteristics of the torque-speed curve in a synchronous motor?

The torque-speed curve of a synchronous motor is relatively flat at synchronous speed and drops quickly when operating below synchronous speed. It exhibits high torque at rated speed, ideal for constant-speed applications.

35. Can synchronous motors be operated using a single-phase power supply?

While asynchronous motors can run on single-phase power, synchronous motors require a three-phase power supply due to their need for a rotating magnetic field for synchronism.

36. How is the cooling system designed in synchronous motors to maintain optimal operating temperatures?

Cooling systems in synchronous motors, such as air or liquid cooling, are integrated to dissipate heat generated during operation, ensuring optimal temperature and preventing overheating.

37. What are the different types of rotor constructions used in synchronous motors?

Synchronous motors can have different rotor configurations like cylindrical rotors, salient pole rotors, or even interior permanent magnet (IPM) rotors, each offering distinct performance characteristics.

38. How is the magnetic field regulated in a synchronous motor to ensure stability and control?

The excitation system, comprising field windings or permanent magnets, is regulated by adjusting the excitation current or magnetic field strength to maintain stability and control.

39. Can synchronous motors operate in harsh environments, such as those with high levels of vibration or extreme temperatures?

Synchronous motors can be designed to withstand harsh conditions by incorporating robust construction, insulation, and protective measures against environmental factors.

40. What role does the phase sequence play in the operation of synchronous motors?

Correct phase sequence is critical for synchronizing multiple motors or connecting them to a power supply to ensure they rotate in the intended direction without affecting their performance.

41. How is the efficiency of a synchronous motor affected by varying load conditions?

Synchronous motors exhibit optimal efficiency under constant loads, but their efficiency might decrease when subjected to variable or fluctuating loads.

42. Can synchronous motors be used in applications requiring high precision and constant speed control?

Yes, synchronous motors are preferred in applications needing precise speed control and constant rotational speed, such as precision machining or motion control systems.

43. What are the differences between synchronous motors and permanent magnet synchronous motors (PMSM)?

While both operate at synchronous speed, PMSMs have permanent magnets embedded in the rotor, offering higher efficiency and torque density compared to conventional synchronous motors.

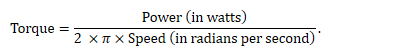

44. How do you calculate the torque produced by a synchronous motor?

The formula to calculate torque in a synchronous motor is

45. What are the implications of under-excitation and over-excitation in synchronous motors?

Under-excitation can lead to reduced power output and overheating, while over-excitation might cause excessive reactive power and instability in the motor.

46. Can synchronous motors operate at speeds higher than their synchronous speed?

Synchronous motors are designed to operate at synchronous speed, and operating above that speed might require modifications or additional equipment.

47. How does the phase angle affect the performance of a synchronous motor?

The phase angle between the stator and rotor magnetic fields determines the motor’s torque production and affects its operating characteristics.

48. What factors influence the choice between synchronous motors and induction motors for specific applications?

Factors such as required speed, torque characteristics, control requirements, and efficiency considerations influence the selection between synchronous and induction motors.

49. How are synchronous motors protected against faults or abnormalities during operation?

Synchronous motors employ protective measures like overcurrent protection, temperature monitoring, vibration analysis, and automatic shutdown systems to prevent damage during faults.

50. Can synchronous motors be used in regenerative braking applications?

Yes, synchronous motors can function in regenerative braking systems, converting mechanical energy into electrical energy when decelerating or stopping machinery.

51. What role does the stator play in the operation of a synchronous motor?

The stator in a synchronous motor generates a rotating magnetic field, inducing currents in the rotor to create a torque that drives the motor.

52. How does the excitation frequency affect the performance of a synchronous motor?

The excitation frequency influences the motor’s magnetic field strength, affecting its torque production and speed regulation capabilities.

53. Can synchronous motors be used in variable speed applications without additional equipment?

Synchronous motors inherently operate at a fixed synchronous speed and require additional control systems like variable frequency drives (VFDs) for efficient variable speed operation.

54. What are the primary challenges in synchronizing multiple synchronous motors in a power system?

Synchronizing multiple motors involves aligning their phase and frequency with the power system, ensuring proper coordination without causing disruptions or imbalances.

55. How does the efficiency of synchronous motors compare to other motor types under constant load conditions?

Synchronous motors typically exhibit higher efficiency compared to induction motors under constant load conditions due to their synchronous speed operation.

56. Can synchronous motors be operated using renewable energy sources like wind or hydro power?

Synchronous motors can be utilized in systems powered by renewable sources by synchronizing their operation with the variable frequency and phase of these sources.

57. What role does the rotor’s saliency or pole shape play in the performance of a synchronous motor?

The rotor’s saliency or pole shape influences the motor’s torque characteristics, allowing optimization for specific applications or load conditions.

58. How does the reluctance torque principle apply to synchronous reluctance motors?

Synchronous reluctance motors operate based on the principle of creating torque due to the tendency of magnetic materials to align with the magnetic field, generating reluctance torque.

59. Can synchronous motors operate without a mechanical load?

Synchronous motors, like other electrical machines, can operate without a mechanical load, but running unloaded for extended periods might cause overheating or inefficient operation.

60. What are the key factors influencing the efficiency improvement in modern synchronous motor designs?

Improved materials, advanced magnetic circuit design, optimized control systems, and reduced losses contribute to the efficiency improvements in modern synchronous motors.

61. How does field weakening impact the performance of a synchronous motor?

Field weakening allows a synchronous motor to operate at speeds higher than its synchronous speed by reducing the excitation to the motor, sacrificing some torque for increased speed.

62. Can synchronous motors be used in traction applications, such as in electric vehicles?

While less common in electric vehicles due to their fixed speed characteristics, synchronous motors can be employed in specific traction applications, especially where constant speed is advantageous.

63. What factors determine the magnitude of torque ripples in synchronous motors?

Torque ripples are influenced by various factors like the motor’s design, magnetic circuitry, and control methods, affecting the smoothness of its operation.

64. How do you calculate the power factor of a synchronous motor using its excitation characteristics?

The power factor can be calculated using the cosine of the phase angle between the current and voltage, determined from excitation characteristics or using power factor correction equipment.

65. What is the impact of operating a synchronous motor with a frequency lower than its rated frequency?

Operating a synchronous motor at a lower frequency might reduce its speed below synchronous speed, affecting its efficiency and torque characteristics.

66. How does the phase-locked loop (PLL) contribute to maintaining synchronism in synchronous motors?

PLLs help synchronize the motor with the power supply by detecting and adjusting the phase and frequency of the motor to ensure proper synchronism.

67. What are the advantages and limitations of using superconducting materials in synchronous motors?

Superconducting materials offer the potential for higher efficiency and power density but face challenges in terms of cooling requirements and material cost.

68. Can synchronous motors be used in parallel with different motor types in the same system?

Synchronous motors can be used in parallel with other synchronous motors or even different motor types, provided they are synchronized to the same frequency and phase.

69. How do you determine the optimal excitation level for a synchronous motor in different operating conditions?

Optimal excitation levels are determined through careful analysis, considering load variations, efficiency requirements, and the motor’s design and characteristics.

70. How does the efficiency of synchronous motors vary with changes in excitation levels?

Efficiency in synchronous motors might vary with changes in excitation levels, typically peaking at certain excitation points while reducing efficiency at extremely high or low levels.

Navigating the realm of Synchronous Motor Interview Questions is an illuminating journey that underscores the depth of knowledge and expertise required in the field of electrical engineering. These questions serve as a litmus test, scrutinizing candidates’ comprehension, analytical prowess, and practical acumen concerning synchronous motors.

As candidates endeavor to conquer the challenges posed by Synchronous Motor Interview Questions, they equip themselves not only with technical proficiency but also with the ability to apply this knowledge to real-world scenarios.

Preparing comprehensively for Synchronous Motor Interview Questions is pivotal for aspiring engineers aiming to secure roles in industries where these motors play a critical role. The thorough grasp of concepts encompassing synchronous motor theory, operational dynamics, control mechanisms, and synchronization methods is indispensable.

Beyond the theoretical understanding, the ability to articulate solutions, demonstrate problem-solving skills, and exhibit a deep understanding of synchronous motors is what sets candidates apart in the competitive landscape of technical interviews. Embracing the complexity and diversity encapsulated within Synchronous Motor Interview Questions, candidates pave the way for a future where their expertise in this domain becomes an invaluable asset, shaping the technological landscape with innovation and precision.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#SynchronousMotor, #MotorInterviewQuestions, #ElectricalEngineering, #EngineeringInterview, #MotorTypes, #SynchronousVsAsynchronous, #MotorControl, #ElectricalJobs, #TechInterviews, #PowerSystems, #ElectricalMotors, #EngineeringCareers, #MotorFundamentals, #ElectricMachines, #SynchronousMachine