Servo Motors: High-Precision Control in Modern Technology

Introduction

Servo motors are an integral part of modern-day technology. Servo motors are used in a wide range of applications, from robotics to manufacturing. These motors are known for their precision, accuracy, and ability to maintain a constant speed. Which makes them ideal for applications where high precision is required. Their ability to maintain a constant speed under varying loads is achieved by using a feedback control mechanism.

Which continuously measures the motor’s position. Then adjusts the power supply to ensure that the motor operates at a consistent speed. This makes servo motors ideal for applications that require precise control over speed and position. Applications include CNC machines, printing presses, and robotics.

Another important feature of servo motors is their high torque-to-inertia ratio. Which makes them very responsive to changes in speed and load. This means that servo motors can accelerate and decelerate very quickly. Which makes them ideal for applications that require rapid movement and precise positioning. With their advanced control systems and efficient energy usage, servo motors are sure to continue playing an important role in the development of new technologies in the years to come. In this article, we will explore the topic of servo motors in-depth, providing a comprehensive understanding of what they are. How they work, and their various applications. The purpose of this article is to provide readers with a thorough understanding of servo motors and their importance in modern technology.

Working & Construction of Servo Motor

A servo motor is an electric motor that utilizes feedback control to accurately control the speed, torque, and position of a rotating shaft. Servo motors operate by receiving electrical signals from a control system that monitors the motor’s position.

Which then adjusts the power supply to ensure that the motor maintains a constant speed and position. This feedback control system ensures that the motor responds quickly and accurately to changes in load and speed. Which makes it ideal for applications that require precision and accuracy.

Servo motors are composed of several components, including the rotor, stator, encoder, feedback loop, and power supply. The rotor is the rotating part of the motor, while the stator is the stationary part. The encoder provides feedback on the motor’s position and speed.

While the feedback loop ensures that the motor maintains a constant speed and position. The power supply provides the electrical energy needed to power the motor. There are several types of servo motors, including DC, AC, and stepper motors. Here’s a detailed cross sectional overview of the servo motor.

DC servo motors

DC servo motors are the most common type of servo motor and are used in a wide range of applications. They operate using a DC power supply and are characterized by their high torque-to-inertia ratio. Which makes them ideal for applications that require high speed and acceleration.

AC servo motors

AC servo motors are similar to DC servo motors but use an AC power supply instead. They are known for their high accuracy and precision. They are often used in applications that require smooth and accurate motion control. Which include robotics, printing presses, and automated machinery.

Stepper motors

Stepper motors are a type of servo motor that operates using a series of electromagnetic pulses to rotate the shaft. They are known for their high precision and accuracy. They are often used in applications that require high-precision motion control, such as 3D printing, CNC machines, and robotics.

How are Servo Motors Controlled?

Servo motors can be controlled using various methods, including analog, digital, and pulse width modulation (PWM).

Analog control involves sending a continuous electrical signal to the motor. Which varies in voltage to control the motor’s speed and position. Analog control is simple but not very precise, making it best suited for applications that do not require high precision.

Digital control involves sending digital signals to the motor. Which allows for more precise control over the motor’s speed and position. Digital control is more complex but also more accurate, making it ideal for applications that require high precision.

PWM control involves modulating the width of a pulse signal to control the motor’s speed and position. PWM control is a very efficient method of controlling servo motors. As it minimizes energy usage and allows for precise control over the motor’s speed and position.

Servo Motor Control With Arduino

The widely used microcontroller platform Arduino can be used to operate servo motors. Servo motors are widely used in robotics and automation because they can accurately control the position, speed, and acceleration of the motor shaft.

To use a servo motor with an Arduino, you will need to connect the motor to one of the PWM pins on the Arduino board. PWM stands for pulse width modulation, which is a technique used to control the amount of power supplied to the motor.

The Arduino provides a library called “Servo” that simplifies the process of controlling servo motors. This library allows you to specify the angle of the motor shaft using degrees, and the Arduino will automatically generate the appropriate PWM signals to control the motor.

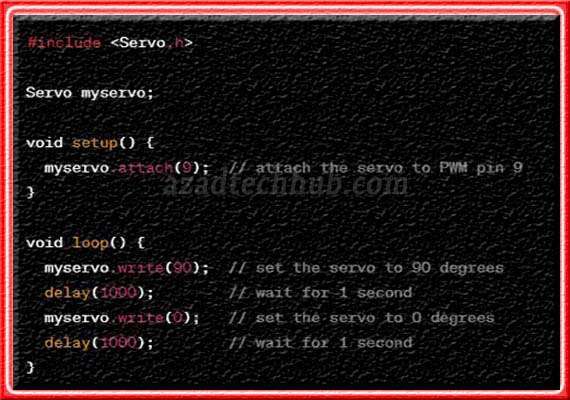

Here’s a simple example code that demonstrates how to control a servo motor using an Arduino:

In this code, we first include the Servo library, create a Servo object called myservo, and attach the servo to PWM pin 9. In the loop() function, we set the servo to 90 degrees using myservo.write(90) and then wait for 1 second using delay(1000). We then set the servo to 0 degrees using myservo.write(0) and wait for another 1 second. The servo will continuously move back and forth between these two positions.

You can modify the code to control the servo motor in different ways, such as setting the speed or acceleration of the motor shaft, or using sensors to adjust the position of the motor based on external inputs.

Role of controllers in servo motor control

Controllers play a critical role in servo motor control. As they are responsible for generating the signals that control the motor’s speed and position. These controllers typically consist of a microprocessor, memory, and input/output circuits. They are programmed to perform specific functions such as position control, speed control, and torque control.

Controllers are typically programmed using a programming language such as C or Assembly. They can be configured to operate in various modes such as open-loop, closed-loop, and PID control.

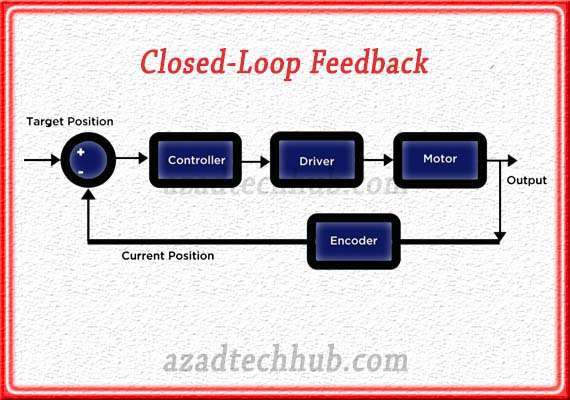

Open-loop control involves sending a signal to the motor without any feedback. While closed-loop control involves using feedback signals to adjust the motor’s speed and position. PID control involves using a feedback loop to adjust the motor’s speed and position. This depends on the error between the desired and actual position.

Importance of feedback loops in controlling servo motors

Feedback loops play a critical role in controlling servo motors. As they allow the motor to adjust its speed and position based on the feedback signal. The feedback loops typically consist of an encoder or sensor that measures the motor’s position. Also a control system that adjusts the motor’s speed and position based on the feedback signal.

Feedback loops are important because they allow the motor to respond quickly and accurately to changes in load and speed. They also ensure that the motor maintains a constant speed and position, even under varying loads.

There are two types of feedback loops used in servo motor control: position feedback and velocity feedback. Position feedback involves using an encoder or sensor to measure the motor’s position. Then adjusts the motor’s speed and position accordingly. Velocity feedback involves using a sensor to measure the motor’s velocity and adjust the motor’s speed and position accordingly.

In short feedback loops are essential in controlling servo motors. As they allow the motor to respond quickly and accurately to changes in load and speed. It also ensures that the motor maintains a constant speed and position. Without feedback loops, servo motors would not be able to provide the high precision and accuracy required in many applications.

Applications of Servo Motors

Servo motors are widely used in different industries due to their high accuracy, precise control, and fast response time. Here are some applications of servo motors in different industries:

Manufacturing industry:

Servo motors are used in manufacturing industries to control the position, speed, and torque of various machines. They are used in applications such as CNC machines, robotics, conveyor belts, packaging machines, and assembly lines. In the manufacturing industry, servo motors are used in CNC machines. Where they control the position and speed of the cutting tool. They are also used in packaging machines to control the position and speed of the packaging material.

Robotics:

Servo motors are extensively used in robotics to control the movement and position of the robotic arms and joints. They are also used in grippers, actuators, and other robotic components. In the robotics industry, servo motors are used in robotic arms. Where they control the movement and position of the arm and gripper. They are also used in humanoid robots for controlling the joints and movement of the robot.

Aerospace industry:

Servo motors are used in various applications in the aerospace industry. Such as aircraft control systems, missile guidance systems, and satellite positioning systems. They are also used in ground support equipment such as test stands, launch pads, and fueling systems.

In the aerospace industry, servo motors are used in aircraft control systems. Where they control the movement of the control surfaces such as the rudder, elevators, and ailerons. They are also used in satellite positioning systems to control the position of the satellite.

Automotive industry:

Servo motors find applications in the automotive industry to control various systems such as steering, throttle, and brake systems. They employ in electric and hybrid vehicles for controlling the motor and battery. In the automotive industry, servo motors fits in electric power steering systems. Where they control the movement of the steering wheel. They are a best suit in hybrid and electric vehicles to control the motor and battery.

Medical industry:

Servo motors find applications in medical equipment such as MRI machines, surgical robots, and prosthetics. Where they control the movement and position of the equipment. In the medical industry, servo motors find applications in MRI machines to control the position and movement of the patient table. They also utilize in surgical robots to control the movement and position of the robotic arm.

Choosing the right servo motor

Choosing the right servo motor for a specific application involves considering various factors such as torque, speed, accuracy, control, power, and environment. Here are some steps to follow when selecting a servo motor:

Torque, Speed & Accuracy

Determine the torque requirements: The torque requirement of the application should calculate to determine the minimum torque rating required for the servo motor. This we can calculate by multiplying the load torque by the gear ratio. The torque rating of the servo motor should match or exceed the torque requirement of the application.

Determine the speed requirements: The speed requirement of the application should determine to determine the minimum speed rating required for the servo motor. This we can calculate by dividing the required linear or angular speed by the gear ratio. The speed rating of the servo motor should match or exceed the speed requirement of the application.

Determine the accuracy requirements: The accuracy requirement of the application should determine to find the minimum resolution and repeatability required for the servo motor. This we can determine by considering the required positional accuracy and the allowable deviation. The resolution and repeatability of the servo motor should meet the positional accuracy requirement of the application.

Control, Power & Environment

Determine the control requirements: The control requirement of the application should determine to find the type of servo motor required. This we can determine by considering the required control mode (position, velocity, torque), a feedback mechanism (encoder, resolver), and communication protocol (analog, digital). The type of servo motor should match the control requirement of the application.

Determine the power requirements: The power requirement of the application should determine to find the required voltage, current, and power rating of the servo motor. This we can find by considering the required power consumption and the available power source. The voltage, current, and power rating of the servo motor should match the power requirement of the application.

Determine the environmental requirements: The environmental requirement of the application should determine to find the required protection rating of the servo motor. This we can determine by considering the operating temperature range, humidity, dust, and vibration. The protection rating of the servo motor should match the environmental requirement of the application.

Maintenance & Troubleshooting of Servo Motors

Maintenance

Regular maintenance of servo motors is crucial to ensure their efficient and safe operation. Here are some reasons why regular maintenance is important:

Preventive maintenance: Regular maintenance helps to prevent potential problems by identifying and addressing any issues before they become major problems. This can help to extend the lifespan of the servo motor and reduce downtime.

Safety: Regular maintenance helps to ensure the safety of the equipment by identifying and addressing any safety hazards such as loose connections or damaged components.

Performance: Regular maintenance helps to maintain the performance of the servo motor by ensuring that it is operating at its optimal level.

Cost savings: Regular maintenance can help to reduce the overall cost of owning and operating a servo motor by preventing major repairs or replacements.

Troubleshooting

Here are some common problems that can occur with servo motors and how to troubleshoot them:

Motor overheating: This can be caused by excessive loads, inadequate cooling, or incorrect voltage. To troubleshoot, check the load and cooling system, and verify the voltage is within the specified range.

Motor stalling: This can be caused by mechanical binding, incorrect tuning, or incorrect load. To troubleshoot, check for any mechanical issues and retune the servo motor. Then verify that the load is within the specified range.

Encoder errors: This can be caused by damage to the encoder, improper wiring, or incorrect programming. To troubleshoot, check the wiring and programming, and replace the encoder if necessary.

Excessive noise or vibration: This can be caused by loose connections, worn bearings, or incorrect tuning. To troubleshoot, check for loose connections, replace worn bearings, and retune the servo motor.

Incorrect positioning: This can be caused by incorrect programming, worn gears, or incorrect load. To troubleshoot, check the programming, replace worn gears, and verify that the load is within the specified range.

To avoid these problems, regular maintenance is crucial. Which includes cleaning the motor, checking the wiring and connections, verifying the control system settings, and ensuring proper lubrication. By performing regular maintenance, one can avoid common problems and ensure the efficient and safe operation of servo motors.

Advantages of Servo Motors

There are several advantages to using servo motors over other types of motors. Some of the key advantages include:

- High precision and accuracy: Servo motors are known for their high precision and accuracy, making them ideal for applications that require precise motion control.

- Speed and torque control: Servo motors are capable of controlling both speed and torque, making them ideal for applications that require precise control over both parameters.

- Energy efficiency: Servo motors are designed to use energy only when needed, making them more energy-efficient than other types of motors.

- High torque-to-inertia ratio: Servo motors have a high torque-to-inertia ratio, making them ideal for applications that require high speed and acceleration.

- Rapid response time: Servo motors are known for their rapid response time, making them ideal for applications that require quick and accurate movement.

Additionally, servo motors offer a range of benefits over other types of motors. Which makes them an essential component in many industries that require precise motion control and high-performance machinery.

Conclusion

Servo motors are critical components in modern technology that provide high torque, speed, and accuracy for precision control applications. Regular maintenance is crucial to ensure their efficient and safe operation, and troubleshooting common problems involves checking various components such as load, cooling system, voltage, wiring, programming, gears, and load.

The importance of servo motors in modern technology cannot be overstated, as they are used in a wide range of industries to perform critical functions. Further exploration of the topic is encouraged to gain a deeper understanding of the technology and its applications.

Worth Read Posts

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.