IEC Standard for Temperature Rise Test Explained: Limits, Methods & Compliance Checklist

The iec standard for temperature rise test is one of the most important compliance requirements in electrical engineering, especially for switchgear, transformers, busbars, control panels, and industrial equipment. Temperature rise directly affects insulation life, operational safety, reliability, and long-term performance. Excessive heating can lead to premature failure, fire hazards, and costly downtime, which is why international standards strictly regulate this test.

This article explains the iec standard for temperature rise test in a practical and easy-to-understand manner. It covers applicable IEC standards, test methods, temperature limits, measurement techniques, acceptance criteria, and a clear compliance checklist that engineers, manufacturers, and utilities can rely on.

Table of Contents

What Is a Temperature Rise Test According to IEC

A temperature rise test verifies that electrical equipment operates within permissible temperature limits when carrying rated current or load under specified conditions. The iec standard for temperature rise test ensures that heat generated by conductors, contacts, and insulation does not exceed safe values defined by international norms.

In simple terms, the test measures the difference between the operating temperature of a component and the surrounding ambient temperature. This temperature difference is called temperature rise and is the key parameter evaluated during testing.

The test is typically carried out under steady-state conditions, meaning the equipment runs long enough for temperatures to stabilize.

Explore details on Electrical Compliance Testing – Safety Regulations | Best Electrical Services in USA

IEC Standards Covering Temperature Rise Tests

Several IEC standards define temperature rise testing based on equipment type. While the principles remain the same, limits and procedures vary slightly.

Table 1: Common IEC Standards Related to Temperature Rise Test

| IEC Standard | Equipment Covered | Typical Application |

|---|---|---|

| IEC 61439 | Low-voltage switchgear and controlgear | Distribution boards, MCC panels |

| IEC 62271 | High-voltage switchgear and controlgear | GIS, circuit breakers |

| IEC 60076 | Power and distribution transformers | Oil and dry-type transformers |

| IEC 60947 | Low-voltage switchgear devices | Contactors, MCCBs |

| IEC 60529 | Enclosures and thermal considerations | Panel enclosures |

Each of these standards references the iec standard for temperature rise test methodology and defines specific temperature rise limits for materials and components.

Learn more about NFPA 70 National Electrical Code | Electrical Safety Experts

Why Temperature Rise Testing Is Critical

Temperature rise testing is not a formality. It directly impacts safety and compliance.

Key reasons include:

- Preventing insulation degradation and breakdown

- Avoiding loose contact overheating

- Ensuring rated current carrying capability

- Improving service life of equipment

- Meeting regulatory and utility approval requirements

Failure to comply with the iec standard for temperature rise test often results in rejection during type testing or factory acceptance testing.

Know more about Transformer Oil Testing: 9 Important Tests for Healthiness

Test Methods Defined by IEC

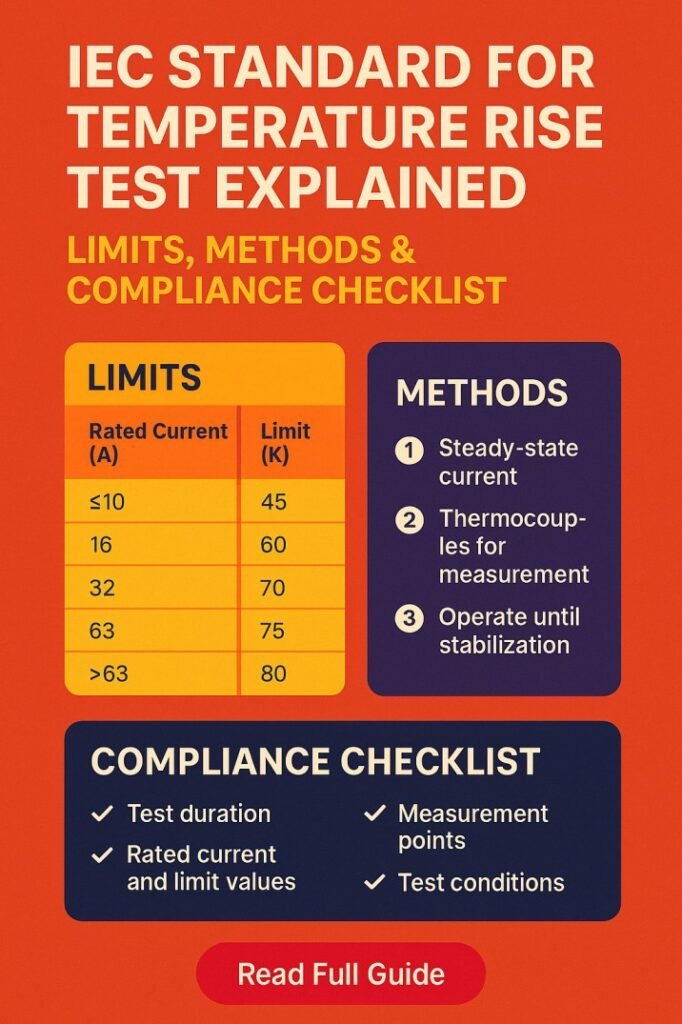

The iec standard for temperature rise test allows multiple measurement methods depending on accuracy requirements and equipment type.

Commonly accepted methods include:

- Thermocouples attached to critical points

- Resistance method based on conductor resistance change

- Infrared thermal imaging for verification

- Embedded temperature sensors in windings or busbars

The resistance method is widely used for windings and conductors where direct temperature measurement is difficult.

Learn more in detail on NEMA 250 Enclosures – Electrical Enclosure Standards | Best Manufacturing Companies in USA

Temperature Rise Limits as Per IEC

Temperature rise limits depend on insulation class, material type, and component function. The ambient reference temperature is usually 40°C unless otherwise specified.

Table 2: Typical IEC Temperature Rise Limits

| Component | Insulation or Material | Max Temperature Rise (K) |

|---|---|---|

| Copper busbars | Bare copper | 70 |

| Terminals | Tin or silver plated | 65 |

| Transformer windings | Class A insulation | 60 |

| Transformer windings | Class F insulation | 100 |

| Control wiring | PVC insulation | 50 |

These limits ensure that the absolute temperature remains within safe operating values even in high ambient conditions. The iec standard for temperature rise test strictly requires compliance with these limits.

Use our online tool Creepage Distance Calculator – Calculate Safe Insulation & Clearance for PCB and High Voltage Design

Test Conditions and Setup Requirements

For accurate results, the test setup must reflect real operating conditions. IEC specifies several requirements that must not be overlooked.

Key conditions include:

- Rated voltage and current applied

- Normal mounting arrangement

- Doors and covers in closed position unless specified

- Natural or forced ventilation as per design

- Stable ambient temperature measurement

Any deviation from standard conditions must be documented clearly in the test report to remain compliant with the iec standard for temperature rise test.

Duration and Stabilization Criteria

A temperature rise test must continue until thermal equilibrium is reached. IEC defines stabilization as a temperature change of less than 1 K over a one-hour period.

Know more about Phase to Phase Clearance as per IEC 61439: Best Guide

In practice:

- Low-voltage panels may stabilize in 4 to 8 hours

- Transformers may require 12 to 24 hours

- High-current busbar systems may take longer

Stopping the test early can invalidate results and lead to non-compliance.

Compliance Checklist for Temperature Rise Test

The following checklist helps ensure full compliance with the iec standard for temperature rise test during type testing or routine verification.

- Applicable IEC standard identified correctly

- Rated current and load applied accurately

- Ambient temperature recorded and documented

- Measurement method selected as per IEC

- Sensors placed at hottest expected points

- Thermal stabilization achieved before recording

- Temperature rise calculated correctly

- Limits verified against insulation class

- Test report prepared with clear data and graphs

Using this checklist reduces the risk of test failure during third-party inspections or audits.

Use our online tool electricity load calculator in kw for home

Common Non-Compliance Issues Observed

Many manufacturers fail temperature rise tests due to avoidable mistakes.

Typical issues include:

- Undersized busbars or cables

- Poor contact pressure at joints

- Inadequate ventilation design

- Incorrect sensor placement

- Ignoring enclosure heat buildup

Addressing these issues early in the design stage improves the chances of passing the iec standard for temperature rise test without costly redesigns.

Read in detail about iec 61439 busbar calculation

Practical Tips for Engineers and Manufacturers

Experienced engineers treat temperature rise testing as a design validation tool rather than a regulatory burden.

Best practices include:

- Performing thermal simulations before testing

- Oversizing critical current paths slightly

- Using high-quality contact materials

- Verifying airflow paths in enclosures

- Conducting pre-compliance thermal checks

These steps help ensure consistent compliance with the iec standard for temperature rise test across product ranges.

Final Thoughts

The iec standard for temperature rise test plays a vital role in ensuring electrical equipment safety, reliability, and international acceptance. Understanding its limits, methods, and compliance requirements helps engineers design better products and avoid costly certification failures. When applied correctly, temperature rise testing becomes a powerful indicator of real-world performance rather than just a laboratory requirement.

Know more about IEC Standard for Earthing System

By following standardized methods, respecting defined limits, and using a structured compliance checklist, manufacturers and utilities can confidently meet IEC expectations and deliver safer electrical systems.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard,#TemperatureRiseTest,#IECTemperatureRise,#ElectricalTestingStandards,#PowerEquipmentTesting,#ThermalTesting,#IECCompliance,#SwitchgearTesting,#TransformerTesting,#ElectricalSafety