IEC Standard for Transformer Oil Breakdown Voltage: Test Method, Limits & Practical Guide

The iec standard for transformer oil breakdown voltage is a critical reference used by utilities, testing laboratories, and maintenance engineers to assess the insulating quality of transformer oil. Transformer oil acts as both an electrical insulator and a cooling medium, and its dielectric strength directly affects transformer reliability.

Table of Contents

A clear understanding of the standard, its test procedure, and acceptable limits helps prevent insulation failure, flashover, and costly outages. This practical guide explains the IEC requirements in a clear and usable way for field engineers and plant operators.

Know more about Transformer Oil Testing: 9 Important Tests for Healthiness

Why breakdown voltage of transformer oil matters

Transformer oil is exposed to electrical stress, heat, moisture, and oxidation throughout its service life. These factors gradually reduce dielectric strength. The iec standard for transformer oil breakdown voltage ensures that oil quality is measured consistently so results from different laboratories remain comparable.

Low breakdown voltage usually indicates contamination such as moisture, fibers, dissolved gases, or aging by-products. If ignored, these issues can lead to partial discharge, internal arcing, or complete transformer failure. Regular testing aligned with IEC standards is therefore an essential part of condition-based maintenance.

Explore details on Electrical Compliance Testing – Safety Regulations | Best Electrical Services in USA

Overview of IEC standards related to BDV testing

The primary document governing the breakdown voltage test is IEC 60156. This standard defines electrode geometry, test voltage rise rate, oil preparation, and result interpretation. When engineers refer to the iec standard for transformer oil breakdown voltage, they are generally pointing to IEC 60156 used alongside other oil quality standards.

Commonly associated IEC standards include:

- IEC 60156 for dielectric breakdown voltage test

- IEC 60296 for unused mineral insulating oils

- IEC 60422 for supervision and maintenance of mineral oils

- IEC 61125 for oxidation stability

Together, these standards form a complete framework for oil quality assessment.

Test principle under IEC 60156

The breakdown voltage test measures the voltage at which an electric arc occurs between two electrodes immersed in oil. The oil sample is subjected to an increasing AC voltage until breakdown occurs. The iec standard for transformer oil breakdown voltage specifies that the voltage increase must be uniform to avoid misleading results.

Know more about Phase to Phase Clearance as per IEC 61439: Best Guide

The test simulates electrical stress conditions inside a transformer. Clean, dry oil will withstand higher voltages, while contaminated oil breaks down at lower values. Multiple breakdowns are measured to obtain an average value that represents oil condition accurately.

Test apparatus and electrode configuration

IEC 60156 strictly defines the test cell and electrodes to maintain repeatability. The most commonly used electrode type is the mushroom or spherical electrode.

Table 1: IEC 60156 test setup requirements

| Parameter | IEC Requirement |

|---|---|

| Electrode shape | Mushroom or spherical |

| Electrode gap | 2.5 mm or 4.0 mm |

| Voltage type | AC, 50 or 60 Hz |

| Voltage rise rate | 2 kV/s ± 0.2 kV/s |

| Oil volume | Sufficient to fully cover electrodes |

Maintaining clean electrodes and accurate gap spacing is essential. Even small deviations can affect results and make the iec standard for transformer oil breakdown voltage test unreliable.

Use our online tool Creepage Distance Calculator – Calculate Safe Insulation & Clearance for PCB and High Voltage Design

Step-by-step test procedure

Following the correct procedure is just as important as having the right equipment. The IEC method focuses on repeatability and contamination control.

- Collect the oil sample in a clean, dry, sealed container

- Allow the sample to rest to release trapped air bubbles

- Stir gently if required, without introducing moisture

- Fill the test cell carefully to avoid air pockets

- Apply voltage at the specified rate until breakdown occurs

- Record the breakdown voltage

- Repeat the test five or six times on the same sample

- Calculate the average value after discarding abnormal readings

This method ensures the iec standard for transformer oil breakdown voltage delivers consistent and meaningful results for maintenance decisions.

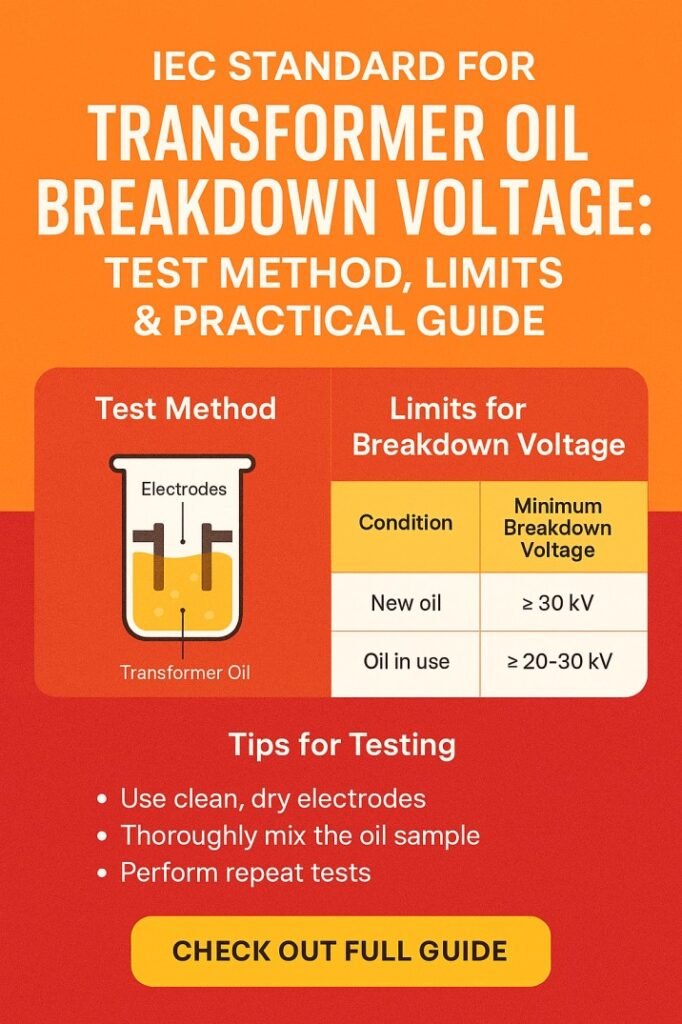

Breakdown voltage limits as per IEC guidance

IEC does not enforce a single universal limit, but it provides guidance values that are widely accepted across the industry. These limits vary based on whether the oil is new, in service, or reclaimed.

Know more about IEC Standard for Busbar Clearance

Table 2: Typical breakdown voltage values based on oil condition

| Oil condition | Electrode gap | Acceptable BDV |

|---|---|---|

| New oil | 2.5 mm | ≥ 70 kV |

| New oil | 4.0 mm | ≥ 60 kV |

| In-service oil | 2.5 mm | ≥ 40 kV |

| In-service oil | 4.0 mm | ≥ 30 kV |

| Poor condition oil | Any | < 30 kV |

When evaluating results under the iec standard for transformer oil breakdown voltage, engineers should always consider transformer voltage class, loading, and environmental conditions.

Factors affecting breakdown voltage results

Several factors can influence BDV readings even when the test method is correct. Understanding these variables helps in proper interpretation.

- Moisture content in oil

- Suspended particles and fibers

- Oil oxidation and aging

- Temperature of the oil sample

- Electrode cleanliness and surface finish

Moisture is the most critical factor. Even a small increase in water content can cause a sharp reduction in BDV. This is why the iec standard for transformer oil breakdown voltage emphasizes careful sample handling.

Know more about IEC Standard for Earthing System

Practical interpretation for maintenance engineers

A single low BDV reading should not immediately trigger oil replacement. Trend analysis is more valuable than isolated data. If BDV gradually decreases over time, corrective actions can be planned.

Practical actions based on results:

- Filtration and dehydration for moderate BDV reduction

- Oil regeneration for aged but recoverable oil

- Complete oil replacement if BDV remains low after treatment

Using the iec standard for transformer oil breakdown voltage as a benchmark allows maintenance teams to make cost-effective decisions without compromising reliability.

Common mistakes during BDV testing

Errors during testing can lead to false conclusions. Many field issues arise due to poor practices rather than oil condition.

- Using contaminated or wet test cells

- Incorrect electrode gap setting

- Rapid voltage rise beyond IEC limits

- Testing oil immediately after sampling

- Ignoring temperature stabilization

Avoiding these mistakes ensures compliance with the iec standard for transformer oil breakdown voltage and improves confidence in the results.

Know more about IEC Standard for MV Cable Testing: Complete Acceptance, Routine & Type Test Guide

Comparison with other international standards

While IEC standards are widely accepted globally, other standards exist. ASTM D1816 and ASTM D877 are commonly used in North America. However, the iec standard for transformer oil breakdown voltage is often preferred for its stricter control of test parameters and higher sensitivity to contamination.

IEC methods are especially effective for modern power transformers where insulation margins are tighter and early fault detection is essential.

Best practices for long-term oil quality management

Breakdown voltage testing should not be done in isolation. It works best when combined with other oil tests.

Recommended complementary tests:

- Moisture content by Karl Fischer method

- Dissolved gas analysis

- Acidity and interfacial tension

- Dielectric dissipation factor

Together with the iec standard for transformer oil breakdown voltage, these tests provide a complete picture of transformer insulation health.

Know more about IEC Standard for Insulation Resistance Test – Procedures, Limits & Best Practices Explained

Conclusion

The iec standard for transformer oil breakdown voltage plays a vital role in ensuring the safe and reliable operation of power transformers. By following IEC 60156 test procedures, understanding acceptable limits, and interpreting results correctly, engineers can detect insulation problems early and extend transformer life.

Consistent testing, proper sample handling, and trend-based analysis transform BDV measurements from a routine test into a powerful maintenance tool. For utilities and industrial plants alike, adherence to this standard is not just good practice, but a foundation for long-term asset reliability.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard, #TransformerOilBDV, #BreakdownVoltageTest, #IEC60156, #TransformerMaintenance, #ElectricalTesting, #PowerTransformer, #InsulatingOil, #HighVoltageTesting, #SubstationEngineering