TOP 120 Interview Questions on Motors: Best Guide

Aspiring engineers entering the jobs of electrical engineering often encounter a rigorous selection process that scrutinizes their grasp of motor-related principles and applications. The exploration of Interview Questions on Motors serves as a pivotal preparatory step for candidates seeking roles where expertise in this domain is paramount.

These questions are a testament to the multifaceted nature of motors, ranging from foundational inquiries to intricate problem-solving scenarios, thereby evaluating candidates’ comprehensive understanding and practical acumen in the diverse landscape of motor technologies.

The landscape of Interview Questions on Motors encompasses a wide spectrum of inquiries, probing candidates’ knowledge on various types of motors, their operational principles, applications across industries, and intricacies in control and maintenance.

Excelling in responses to Interview Questions on Motors demands a holistic approach, requiring candidates to navigate through the nuances of different types of motors such as DC motors, AC motors, stepper motors, and synchronous motors, among others.

The ability to articulate concise yet comprehensive explanations, coupled with the capacity to apply theoretical knowledge to practical scenarios, distinguishes candidates as adept professionals capable of meeting the demands of the ever-evolving field of electrical engineering.

Interview Questions on Motors

1. What are the different types of motors used in various industries?

Motors come in various types such as AC (Alternating Current) motors including Induction, Synchronous, and Universal motors, and DC (Direct Current) motors like Brushed DC and Brushless DC motors. Each type has specific applications based on their characteristics.

2. Explain the working principle of an Induction Motor

An induction motor operates on electromagnetic induction principles. When AC current flows through the stator windings, it generates a rotating magnetic field. This field induces currents in the rotor, producing torque and causing the rotor to rotate.

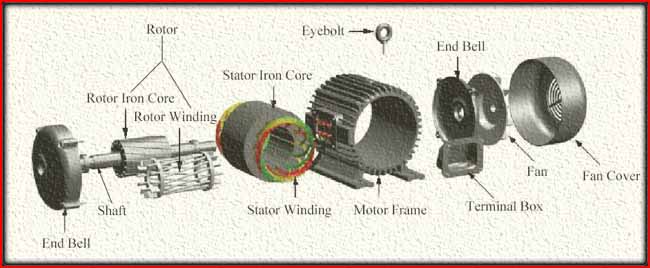

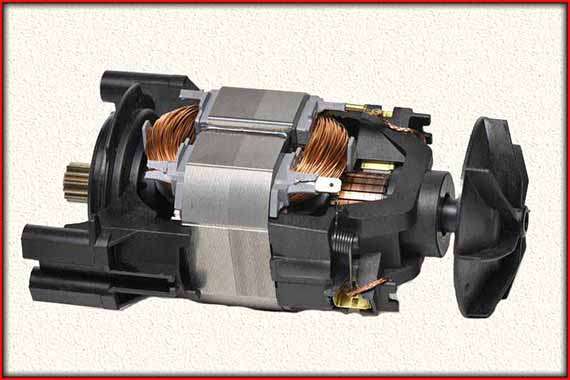

3. What are the main components of a DC motor, and how do they function?

A DC motor consists of a stator (field magnet), rotor (armature), commutator, and brushes. The stator generates a magnetic field, while the rotor carries the armature windings. The commutator and brushes facilitate the flow of current, ensuring continuous rotation.

4. How does a synchronous motor differ from an induction motor?

Synchronous motors operate at a constant speed determined by the frequency of the power supply and the number of poles, while induction motors have a speed slightly lower than synchronous speed due to slip. Synchronous motors require an external DC power source for excitation, unlike induction motors.

5. Can you explain the concept of back EMF in DC motors?

Back electromotive force (EMF) is generated in a DC motor when the rotor rotates within the magnetic field produced by the stator. It opposes the applied voltage, controlling the current and regulating the motor’s speed.

6. What are the factors influencing the efficiency of a motor?

Efficiency is affected by various factors like motor design, operating conditions, losses in the motor (mechanical, electrical, magnetic), and the quality of materials used in construction.

7. Describe the process of controlling the speed of a DC motor.

The speed of a DC motor can be controlled using methods like varying the input voltage, altering the armature or field winding resistance, or using pulse-width modulation (PWM) techniques in modern electronic drives.

8. How do you detect and troubleshoot motor faults in industrial settings?

Motor faults can be identified through analysis of vibrations, temperature variations, abnormal noises, or abnormal current draw. Troubleshooting involves inspections, tests, and sometimes disassembly to identify and rectify issues.

9. Explain the significance of the rotor in a synchronous motor.

The rotor in a synchronous motor contains the field winding or permanent magnets, enabling the motor to maintain synchronism with the stator’s rotating magnetic field, resulting in constant speed operation.

10. What measures are taken to ensure safety while working with motors?

Safety measures include following proper lockout/tagout procedures, wearing personal protective equipment, understanding electrical safety protocols, and adhering to manufacturer guidelines for maintenance and operation.

11. What are the advantages and limitations of using a Brushless DC motor over a Brushed DC motor?

Brushless DC motors offer higher efficiency, lower maintenance due to the absence of brushes, and reduced electromagnetic interference. However, they tend to be more complex and costlier to control compared to brushed DC motors.

12. Describe the significance of the commutator in a DC motor.

The commutator in a DC motor is crucial for converting AC to DC within the motor, ensuring continuous rotation. It reverses the current direction in the rotor windings to maintain the rotational direction of the motor.

13. How does the number of poles in a motor affect its speed and torque characteristics?

The number of poles directly influences the motor’s speed and torque characteristics. More poles usually result in lower speeds with higher torque, while fewer poles lead to higher speeds with lower torque.

14. Explain the importance of the phase sequence in three-phase motors.

The correct phase sequence in three-phase motors ensures the proper rotation direction. Incorrect phase sequences might cause reverse rotations, potentially damaging equipment or affecting efficiency.

15. Can you differentiate between a reluctance motor and an induction motor?

Reluctance motors operate on the principle of the rotor aligning with the rotating magnetic field due to reluctance torque. In contrast, induction motors rely on induction to produce the necessary torque for rotation.

16. What factors contribute to motor losses, and how can they be minimized?

Motor losses stem from resistance in windings, core losses, friction, and stray losses. These losses can be minimized by using high-quality materials, efficient designs, and proper maintenance practices.

17. How does the starting torque of an induction motor compare to its running torque?

The starting torque of an induction motor is higher than its running torque due to the rotor’s initial resistance and inertia during start-up.

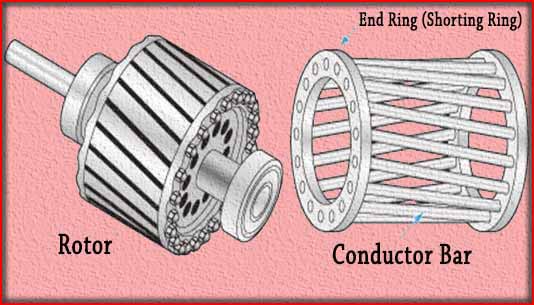

18. Explain the role of the rotor bars in an induction motor.

Rotor bars in an induction motor facilitate the production of a rotating magnetic field, allowing the motor to operate efficiently through electromagnetic induction.

19. Can you elaborate on the operation of a universal motor?

A universal motor operates on both AC and DC supplies and finds applications in devices requiring high starting torque, such as household appliances and power tools.

20. What are the implications of overloading a motor beyond its rated capacity?

Overload in motor can lead to overheating, increased wear and tear, decreased efficiency, and potentially irreversible damage, shortening the motor’s lifespan.

Know more about how to select overload relay for motor

Interview Questions on Motors tend to explore the synchronization methods. Candidates find themselves dissecting various techniques used to synchronize these motors with the power supply.

21. What are the key differences between synchronous and asynchronous motors?

Synchronous motors operate at a fixed speed determined by the frequency of the power supply and the number of poles, whereas asynchronous motors, like induction motors, have a speed slightly lower than synchronous speed due to slip.

22. Can you explain the role of the stator in a motor’s operation?

The stator in a motor generates a rotating magnetic field, either by applying an alternating current (in AC motors) or a constant magnetic field (in DC motors), which interacts with the rotor to produce motion.

23. How do you calculate motor efficiency, and what factors affect it?

Motor efficiency is calculated as the ratio of output power to input power. Factors affecting efficiency include the motor’s design, losses due to resistance, friction, and the quality of materials used.

24. Describe the significance of the armature winding in DC motors.

The armature winding in a DC motor is located on the rotor and is crucial for generating the motor’s electromagnetic field. It interacts with the stator’s magnetic field, producing torque and rotation.

25. How does the load affect the speed regulation of a motor?

The speed regulation of a motor refers to its ability to maintain a relatively constant speed under varying loads. Heavy loads might cause a reduction in speed, affecting the motor’s performance.

26. Explain the impact of supply voltage variations on motor operation.

Voltage variations can affect the motor’s performance, altering its speed, torque, and efficiency. Extreme voltage fluctuations might lead to motor damage or inefficiencies.

27. What measures can be taken to improve the power factor of a motor?

Improving the power factor involves techniques such as using power factor correction capacitors, adjusting the motor’s load, or utilizing more efficient motor designs.

28. Can you differentiate between torque and horsepower in motor specifications?

Torque represents the rotating force generated by the motor, while horsepower refers to the rate at which work is done, calculated as a function of torque and speed.

29. How does a variable frequency drive (VFD) affect motor speed control?

A VFD controls motor speed by altering the frequency and voltage supplied to the motor, enabling precise and efficient speed regulation.

30. What safety precautions should be followed while working with motors?

Safety measures include ensuring proper grounding, using appropriate personal protective equipment (PPE), following lockout/tagout procedures, and understanding electrical hazards.

31. Can you explain the significance of slip in induction motors?

Slip in induction motors represents the difference between synchronous speed and the actual rotor speed. It’s crucial for generating the motor’s torque.

32. What are the key differences between a single-phase and three-phase motor?

Single-phase motors operate on a single alternating current, suitable for smaller applications. Three-phase motors use three alternating currents, offering higher efficiency and smoother operation for larger systems.

33. How does the thermal protection system work in preventing motor overheating?

Thermal protection systems in motors employ sensors to monitor temperature. If the temperature exceeds safe limits, the system initiates automatic shutdown or alerts to prevent motor damage.

34. Explain the impact of different motor enclosures on motor performance.

Motor enclosures, such as open, totally enclosed, or explosion-proof enclosures, protect the motor from external factors like dust, moisture, or hazardous environments, influencing motor durability and performance.

35. What are the main factors considered when selecting a motor for variable speed applications?

For variable speed applications, considerations include the motor’s speed range, torque characteristics, efficiency at different speeds, and compatibility with speed control devices.

36. How does the construction of the rotor impact the efficiency of a motor?

Rotor construction materials, shape, and winding configurations significantly affect the motor’s efficiency and performance under various loads.

37. Can you differentiate between continuous and intermittent duty motors?

Continuous duty motors are designed for continuous operation without rest, while intermittent duty motors operate in cycles, needing cool-down periods between operations.

38. Explain the role of bearings in motor operation and longevity.

Bearings support the rotating components, reducing friction and allowing smooth operation. Proper lubrication and maintenance of bearings are critical for extending motor life.

39. What are the methods used for motor starting, and how do they impact motor performance?

Starting methods like direct-on-line (DOL) starting, star-delta starting, or soft starters influence motor torque, current draw, and mechanical stress during startup.

40. Can you elaborate on the effects of harmonics on motor performance?

Harmonics in the power supply can lead to increased motor heating, reduced efficiency, and potential damage due to excessive vibrations or torque pulsations.

Beyond the technical aspects, Interview Questions on Motors often probe candidates about the broader impact and future trends in the field. Questions might delve into the role of motors in the context of sustainability and energy efficiency, prompting candidates to contemplate innovative approaches and emerging technologies that drive efficiency in motor operations.

41. How does the selection of winding configurations impact the performance of an induction motor?

Different winding configurations, such as delta and star connections, affect the motor’s starting torque, operating efficiency, and current draw.

42. Explain the importance of motor insulation in ensuring safe operation.

Motor insulation protects against electrical faults and ensures safety. Proper insulation prevents current leakages and reduces the risk of electrical hazards.

43. What are the different starting methods used in three-phase induction motors?

Starting methods include direct-on-line (DOL), star-delta, autotransformer, and soft starters, each with varying effects on motor starting torque and current.

44. How does motor synchronization affect the performance of motors in a system?

Motor synchronization ensures balanced operation in systems with multiple motors, preventing issues like phase imbalances or overloading in the network.

45. Can you explain the concept of regenerative braking in motors?

Regenerative braking allows motors to recover and convert kinetic energy into electrical energy during braking, feeding it back to the power supply, enhancing efficiency in certain applications.

46. Describe the impact of altitude and ambient temperature on motor performance.

Altitude and ambient temperature affect motor cooling, efficiency, and the motor’s ability to dissipate heat, requiring adjustments in motor design or cooling mechanisms.

47. How does a centrifugal switch function in single-phase induction motors?

The centrifugal switch disconnects the start winding circuit once the motor reaches a certain speed, ensuring smooth transition from starting to running mode.

48. Explain the working principle behind a stepper motor.

Stepper motors operate by converting electrical pulses into precise mechanical movements, rotating in fixed angular increments, often used in precision control applications.

49. What measures can be taken to reduce motor noise and vibrations?

Balancing rotor components, ensuring proper alignment, using dampening materials, and employing vibration isolators can reduce noise and vibrations in motors.

50. Can you discuss the role of motor control systems in achieving precise motor operation?

Motor control systems, including PLCs (Programmable Logic Controllers) and PID (Proportional-Integral-Derivative) controllers, enable precise speed control, torque adjustments, and operational automation.

51. What are the factors influencing the choice between a synchronous and an asynchronous motor for specific applications?

Factors such as speed control requirements, starting torque, operating environment, and cost considerations influence the selection between synchronous and asynchronous motors.

52. How do you determine the efficiency of a motor under varying loads?

Efficiency can be determined by measuring input power and output power under different load conditions, allowing the calculation of efficiency at each operating point.

53. Can you explain the concept of slip in an induction motor and its impact on motor performance?

Slip in an induction motor is the difference between synchronous speed and actual rotor speed. It affects torque production, efficiency, and the motor’s ability to handle varying loads.

54. What are the advantages and disadvantages of using a gearbox with a motor system?

Gearboxes can increase torque, adjust speed, and match mechanical loads but might introduce complexity, efficiency losses, and require additional maintenance.

55. Describe the role of the V-curve in determining the operating limits of a motor.

The V-curve depicts the safe operating region of a motor concerning voltage and frequency variations, ensuring the motor operates within its specified limits.

56. How do you identify the ideal motor for high-speed or high-torque applications?

Selecting the ideal motor involves evaluating speed-torque characteristics, power requirements, and considering specific application demands.

57. Explain the differences between a linear motor and a rotary motor.

A linear motor produces motion in a straight line, while a rotary motor generates rotational motion. Each serves different applications based on their motion characteristics.

58. Can you elaborate on the role of Hall effect sensors in brushless DC motors?

Hall effect sensors provide rotor position feedback in brushless DC motors, enabling precise electronic commutation and ensuring smooth operation.

59. Discuss the impact of different motor cooling methods on motor efficiency and lifespan.

Cooling methods like air, liquid, or fan-assisted cooling impact motor efficiency by regulating temperatures and affecting the motor’s ability to dissipate heat.

60. How do you evaluate motor performance in terms of torque-speed characteristics?

Torque-speed curves depict a motor’s torque output concerning speed variations, aiding in understanding the motor’s capabilities under different load conditions.

61. What are the different methods used for motor insulation resistance testing?

Motor insulation resistance can be tested using methods like the spot test, polarization index test, and dielectric absorption test, ensuring the insulation’s integrity.

62. How does the efficiency of a motor change with variations in operating temperature?

Motor efficiency might decrease at higher operating temperatures due to increased resistive losses, impacting the motor’s overall performance.

63. Can you explain the role of commutation in DC motors and its impact on motor efficiency?

Commutation in DC motors ensures continuous rotation by reversing the current in the rotor windings, influencing motor efficiency and reducing wear on brushes and commutators.

64. Describe the methods employed for motor maintenance and their significance in preventing failures.

Motor maintenance includes tasks like lubrication, bearing inspections, cleaning, and electrical testing, crucial for preventing failures and ensuring optimal performance.

65. How do you determine the power factor of a motor using measurements?

Power factor can be determined using power analyzers or meters, measuring the phase angle between voltage and current to assess motor efficiency.

66. Explain the concept of cogging and crawling in induction motors.

Cogging refers to the motor’s tendency to resist starting due to magnetic locking, while crawling involves a motor running at speeds lower than normal due to irregular supply voltages.

67. What are the primary differences between AC and DC motors in terms of their construction and applications?

AC motors operate using alternating current and are suitable for high-power applications, while DC motors use direct current and find usage in specific speed and torque control applications.

68. How does the use of soft magnetic materials impact the efficiency of a motor?

Soft magnetic materials in motor cores reduce hysteresis losses and eddy current losses, enhancing the motor’s efficiency.

69. Discuss the significance of motor nameplate data in selecting and operating motors.

Motor nameplate data contains vital information like voltage, current, horsepower, efficiency, and speed ratings, aiding in proper motor selection and maintenance.

70. Can you describe the concept of dynamic braking and its application in motors?

Dynamic braking uses the motor’s reverse torque to slow down or stop motion, dissipating excess energy as heat, often employed in applications requiring rapid deceleration.

71. How does the construction of the motor windings impact motor performance and efficiency?

The construction and arrangement of motor windings influence factors such as resistance, inductance, and magnetic field distribution, affecting motor efficiency and characteristics.

72. Can you explain the role of the inverter in controlling the speed of an induction motor?

Inverters regulate the speed of induction motors by adjusting the frequency and voltage of the supplied power, enabling precise control over motor speed.

73. Discuss the differences between series and shunt wound DC motors and their respective applications.

Series-wound DC motors offer high starting torque, suitable for applications like traction and some industrial uses, whereas shunt-wound motors provide more constant speed and find applications in conveyors and pumps.

74. How do you ensure proper motor alignment, and why is it critical for motor efficiency?

Proper alignment of motor components, such as shafts and couplings, prevents excess vibration and mechanical stress, contributing to increased motor efficiency and longevity.

75. Explain the concept of motor cogging torque and its impact on motor performance.

Cogging torque is the reluctance of a motor to start due to magnetic interactions, causing jerky or hesitant movement at low speeds, affecting the motor’s efficiency and smooth operation.

76. What measures can be taken to mitigate the effects of motor harmonics on power systems?

Applying harmonic filters, using power quality correction devices, and proper system design can reduce the impact of motor harmonics, improving power quality.

77. Describe the advantages and limitations of using permanent magnet motors in various applications.

Permanent magnet motors offer high efficiency, compact size, and simplified control but might be limited by higher initial costs and temperature sensitivity.

78. How does the choice of motor enclosure impact the motor’s environmental resilience and protection?

Motor enclosures like TEFC (Totally Enclosed Fan Cooled) or TENV (Totally Enclosed Non-Ventilated) provide varying degrees of protection against moisture, dust, and corrosive environments, ensuring motor durability.

79. Can you elaborate on the effects of overloading a motor and its long-term consequences?

Overloading a motor can lead to increased heat, reduced efficiency, insulation degradation, and eventually, motor failure or damage.

80. Discuss the importance of surge protection devices in safeguarding motors from electrical damage.

Surge protection devices safeguard motors by diverting excessive voltage surges or spikes away from the motor, preventing electrical damage.

81. What are the primary differences between a wound rotor and a squirrel cage induction motor?

Wound rotor induction motors have windings on the rotor, allowing external resistance control for improved starting torque, while squirrel cage induction motors have rotor bars for robust, maintenance-free operation.

82. Explain the role of motor insulation classes and their significance in motor selection.

Motor insulation classes indicate the thermal capabilities of the insulation material, guiding motor selection based on the maximum allowable operating temperature and environmental conditions.

83. How does the number of poles in a motor influence its speed and torque characteristics?

More poles generally lead to lower speeds with higher torque, while fewer poles result in higher speeds with lower torque, impacting the motor’s overall performance.

84. Discuss the impact of harmonics on motor overheating and its preventive measures.

Harmonics in power systems can cause increased motor heating, leading to efficiency loss and reduced lifespan. Mitigating measures include harmonic filters and proper system design.

85. Can you elaborate on the significance of motor protection devices in safeguarding against faults?

Motor protection devices such as overload relays, thermal sensors, and circuit breakers prevent motor damage by detecting faults like overcurrent, overheating, or short circuits.

86. Explain the concept of synchronous reluctance motors and their advantages.

Synchronous reluctance motors operate without permanent magnets, relying on rotor geometry to generate torque. They offer high efficiency, simple construction, and low maintenance.

87. How do you select the appropriate motor enclosure for harsh environments like chemical plants or marine applications?

For harsh environments, selecting motors with IP (Ingress Protection) ratings and specific enclosures like TEFC or explosion-proof enclosures ensures protection against moisture, dust, or corrosive elements.

88. Discuss the role of commutation frequency in brushless DC motor operation and efficiency.

Commutation frequency in brushless DC motors determines the speed and torque characteristics, impacting the motor’s efficiency and control.

89. How do you determine the maximum allowable temperature rise in a motor and its significance?

The maximum allowable temperature rise in a motor is determined by its insulation class and rated temperature, ensuring safe operation within specified limits.

90. Can you explain the advantages and limitations of using a multi-speed motor in various applications?

Multi-speed motors offer flexibility in matching speed requirements but might have increased complexity and cost compared to single-speed motors.

91. Explain the impact of load fluctuations on motor efficiency and longevity.

Load fluctuations can affect motor efficiency by causing overheating during high loads or inefficient operation at low loads, impacting the motor’s lifespan.

92. Can you discuss the role of field weakening in controlling the speed of a DC motor?

Field weakening allows the control of DC motor speed beyond its rated speed by reducing the field flux, enabling higher speeds with decreased torque.

93. Describe the operation and advantages of a switched reluctance motor.

Switched reluctance motors operate without permanent magnets, relying on magnetic reluctance to generate torque, offering robustness and simpler construction.

94. How does motor derating apply in situations where operating conditions differ from standard specifications?

Motor derating involves reducing a motor’s operational capabilities when operating conditions deviate from standard specifications to ensure reliability and longevity.

95. Discuss the significance of motor bearings and their maintenance in ensuring optimal motor performance.

Motor bearings support rotor movement, and proper lubrication and maintenance are crucial to prevent friction, reduce wear, and extend the motor’s lifespan.

96. Explain the concept of motor slip and its implications on motor performance.

Motor slip is the difference between synchronous speed and the actual rotor speed, impacting torque production and the motor’s ability to handle varying loads.

97. How do you select the appropriate motor cooling method based on specific applications?

Selecting motor cooling methods (air, liquid, or fan-assisted) depends on factors like environmental conditions, heat dissipation requirements, and the motor’s power rating.

98. Discuss the differences between torque control and speed control in motor applications.

Torque control regulates the motor’s torque output, while speed control manages the motor’s rotational speed, each used for specific performance requirements.

99. Can you explain the significance of the power factor in motor applications and its relationship with efficiency?

A higher power factor indicates better energy utilization and improved motor efficiency, minimizing energy losses and reducing system strain.

100. Describe the advantages and limitations of using a direct-drive motor compared to geared motors in specific applications.

Direct-drive motors offer simplicity, reduced maintenance, and increased efficiency but might have limitations in torque range or speed variations compared to geared motors.

101. What are the primary differences between a synchronous reluctance motor and a permanent magnet synchronous motor?

Synchronous reluctance motors rely on rotor geometry to generate torque, whereas permanent magnet synchronous motors use permanent magnets for torque production.

102. Explain the significance of motor insulation resistance testing and its role in maintenance.

Insulation resistance testing ensures the integrity of motor insulation, preventing electrical faults and supporting overall motor health as part of routine maintenance.

103. How does the choice of motor enclosure affect motor efficiency and protection in outdoor applications?

Choosing weatherproof enclosures with appropriate IP ratings ensures protection against moisture, dust, and other environmental factors, influencing motor efficiency and longevity.

104. Discuss the impact of unbalanced voltage and current on motor operation and its preventive measures.

Unbalanced voltage and current can cause overheating, vibration, and reduced motor lifespan. Balancing phase voltages and loads helps prevent such issues.

105. Can you explain the working principle behind a reluctance torque motor?

Reluctance torque motors operate based on the tendency of magnetic materials to seek lower reluctance paths, generating torque by aligning with the magnetic field.

106. Describe the significance of motor start-stop cycles and their influence on motor wear and tear.

Frequent start-stop cycles can increase mechanical stress and wear on motor components, affecting efficiency and requiring consideration in motor design.

107. Discuss the role of regenerative braking in enhancing motor efficiency in certain applications.

Regenerative braking allows motors to recover energy during braking, reducing energy wastage and improving overall system efficiency.

108. How does motor control using pulse width modulation (PWM) affect motor speed and efficiency?

PWM control varies the power supplied to the motor by modulating the pulse width, enabling precise speed control and improving efficiency.

109. Explain the impact of mechanical resonance on motor operation and potential mitigation measures.

Mechanical resonance can lead to excessive vibrations and mechanical stress, causing motor failure. Damping or tuning systems can mitigate resonance effects.

110. Describe the advantages and limitations of using a brushless DC motor compared to a brushed DC motor in various applications.

Brushless DC motors offer higher efficiency, lower maintenance, and reduced electromagnetic interference but may be costlier and more complex in control systems than brushed DC motors.

111. What factors should be considered when selecting the appropriate motor for an application with varying load conditions?

Selecting a motor for varying load conditions involves evaluating speed-torque characteristics, efficiency at different loads, and the motor’s ability to handle variable torque requirements.

112. Discuss the impact of voltage and frequency variations on the performance of a motor and the precautions to mitigate these effects.

Voltage and frequency variations can affect motor speed, torque, and efficiency. Using voltage regulators or frequency converters helps mitigate these effects.

113. How do you determine the appropriate motor size and type for specific industrial applications?

Choosing the right motor size involves evaluating power requirements, duty cycles, environmental conditions, and load characteristics relevant to the industrial application.

114. Explain the importance of motor insulation resistance testing and its relation to motor safety.

Insulation resistance testing ensures the integrity of motor insulation, preventing electrical faults and minimizing the risk of electric shock or fire hazards.

115. Can you discuss the advantages and limitations of using a linear induction motor in comparison to a rotary motor?

Linear induction motors offer linear motion without mechanical components but may have limitations in terms of speed control and complex construction.

116. Describe the role of a soft starter in reducing motor stress during startup and its benefits.

Soft starters gradually ramp up the motor’s voltage, reducing the initial stress and current surges during startup, thus extending the motor’s lifespan.

117. Discuss the impact of an unbalanced load on three-phase motors and its corrective measures.

An unbalanced load can lead to motor overheating and reduced efficiency. Balancing loads across phases and using phase correction devices help address this issue.

118. Can you elaborate on the importance of motor winding insulation classes and their impact on motor reliability?

Motor insulation classes define the thermal capabilities of the insulation, ensuring safe operation within specified temperature limits, crucial for motor reliability.

119. Explain the significance of torque-speed curves in motor performance evaluation and motor selection.

Torque-speed curves help understand a motor’s torque output at different speeds, aiding in motor selection for specific application requirements.

120. Discuss the factors influencing the efficiency and performance of motors in energy-saving applications.

Factors such as motor design, size, speed control methods, and system integration impact motor efficiency in energy-saving applications.

Mastering the diverse terrain of Interview Questions on Motors is a testament to the commitment and depth of knowledge essential for aspiring engineers in the field of electrical machinery. Beyond the technical aspects, these questions encapsulate the essence of problem-solving skills, critical thinking, and the ability to apply theoretical concepts to practical scenarios.

Engaging with Interview Questions on Motors is not merely a preparatory exercise; it’s a journey that equips candidates with a profound understanding of motor dynamics, positioning them as competent professionals ready to navigate the intricacies of this ever-evolving domain.

The multifaceted nature of Interview Questions on Motors underscores the need for a comprehensive understanding of various motor types, their operational intricacies, and their applications across industries. As candidates delve into the depths of these questions, they cultivate an expertise that extends beyond theoretical knowledge, encompassing hands-on problem-solving abilities and a knack for innovation.

Excelling in Interview Questions on Motors isn’t just about demonstrating expertise; it’s about showcasing the agility to adapt to technological advancements and contribute meaningfully to the landscape of electrical engineering, steering it toward new frontiers of innovation and efficiency.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#MotorInterviewQuestions, #ElectricalEngineering, #MotorBasics, #InductionMotor, #DCMotor, #MotorControl, #EngineeringJobs, #ElectricalInterview, #MotorTechnology, #ElectricalConcepts, #MechanicalToElectrical, #MotorWorking, #MotorTroubleshooting, #ElectricMotors, #MotorTypes