Types of Transmission Line Conductors Explained: Best Guide for Power Engineers

Transmission lines are the backbone of power systems, carrying electrical energy from generating stations to substations and load centers. The performance, reliability, and efficiency of a power transmission network depend heavily on the conductor used. For engineers, students, and professionals in the power sector, understanding the types of transmission line conductors is essential for proper design and selection. Each conductor type has unique electrical, mechanical, and economic characteristics that make it suitable for specific voltage levels and environmental conditions.

Table of Contents

This article provides a comprehensive explanation of the types of transmission line conductors, their construction, advantages, limitations, and practical applications. The focus remains on real-world usage rather than textbook definitions, helping readers clearly understand why one conductor is preferred over another in actual power systems.

What Is a Transmission Line Conductor

A transmission line conductor is a material used to carry electrical power over long distances at high voltages. It must offer low electrical resistance, high tensile strength, good thermal performance, and resistance to environmental effects. When selecting from different types of transmission line conductors, engineers consider factors such as current-carrying capacity, line losses, sag, corona performance, and cost.

Use our online tool Creepage Distance Calculator – Calculate Safe Insulation & Clearance for PCB and High Voltage Design

Importance of Selecting the Right Conductor

The choice among different types of transmission line conductors directly affects system efficiency and long-term reliability. An unsuitable conductor can result in excessive power losses, higher sag, mechanical failure, or increased maintenance costs. Proper selection ensures stable power delivery and compliance with technical standards.

Key factors influencing conductor selection include:

- Operating voltage level

- Span length and tower design

- Ambient temperature and wind conditions

- Electrical loading and future expansion

- Installation and maintenance cost

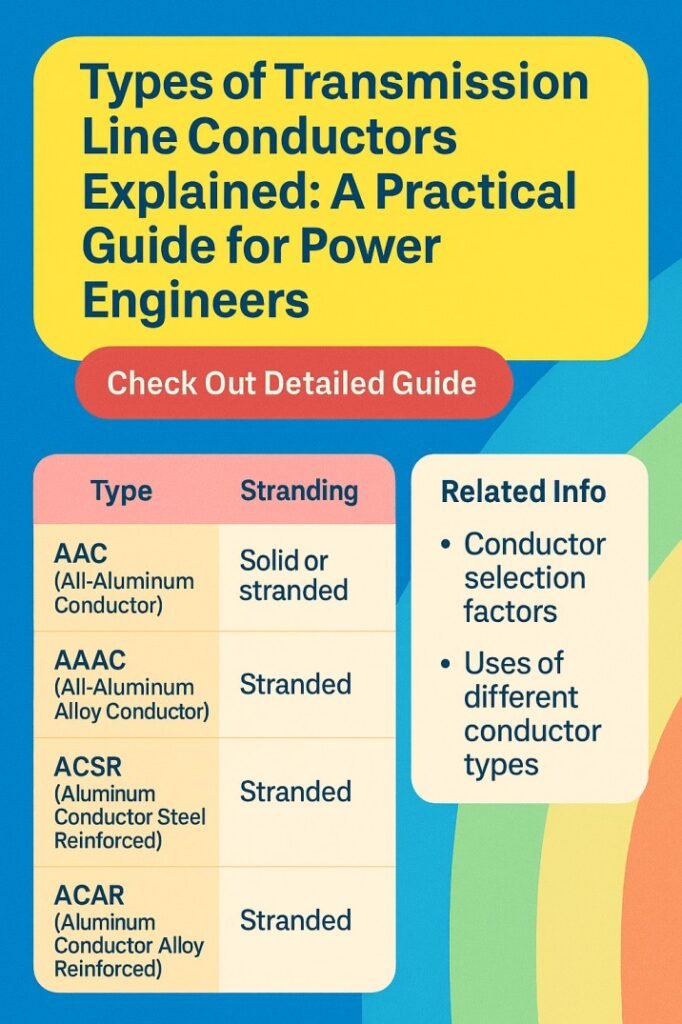

Classification of Transmission Line Conductors

Based on material composition and construction, the types of transmission line conductors are broadly classified into aluminum-based conductors, copper conductors, composite conductors, and special-purpose conductors.

AAC – All Aluminum Conductor

All Aluminum Conductor is one of the simplest and most widely used conductor types in power transmission and distribution systems. It consists of stranded aluminum wires without any steel or composite core.

AAC is mainly used in urban areas where span lengths are short and corrosion resistance is important. Aluminum offers good conductivity and low weight, making it suitable for lower voltage transmission lines.

Advantages of AAC include:

- High electrical conductivity

- Good corrosion resistance

- Lightweight construction

- Easy installation

Know more about Phase to Phase Clearance as per IEC 61439: Best Guide

Limitations include lower tensile strength compared to reinforced conductors. Among the types of transmission line conductors, AAC is not ideal for long spans or high mechanical stress areas.

AAAC – All Aluminum Alloy Conductor

All Aluminum Alloy Conductor is manufactured using aluminum-magnesium-silicon alloy. This improves mechanical strength while maintaining good conductivity. AAAC is commonly used in coastal and industrial regions where corrosion is a major concern.

Compared to AAC, AAAC offers better sag performance and longer service life. It is considered one of the balanced types of transmission line conductors for medium-voltage lines.

Key features of AAAC:

- Higher strength than AAC

- Excellent corrosion resistance

- Reduced sag under load

- Suitable for medium and high voltages

ACSR – Aluminum Conductor Steel Reinforced

ACSR is one of the most commonly used conductors in high-voltage transmission systems. It consists of aluminum strands surrounding a galvanized steel core. The steel core provides mechanical strength, while aluminum strands carry most of the current.

Because of its strength and durability, ACSR is widely selected among the types of transmission line conductors for long spans and heavy loading conditions.

Main advantages of ACSR:

- High tensile strength

- Suitable for long spans

- Proven performance in overhead lines

- Cost-effective for high-voltage transmission

Use our online tool Creepage Distance Calculator – Calculate Safe Insulation & Clearance for PCB and High Voltage Design

However, steel reinforcement makes ACSR heavier and more prone to corrosion in aggressive environments.

ACAR – Aluminum Conductor Alloy Reinforced

Aluminum Conductor Alloy Reinforced combines aluminum alloy strands with pure aluminum strands. This design provides a good balance between electrical performance and mechanical strength.

ACAR is often used where higher current capacity is required without significantly increasing conductor diameter. Among modern types of transmission line conductors, ACAR offers flexibility in design.

Typical applications include:

- Sub-transmission lines

- River crossings

- Areas with moderate mechanical stress

Copper Conductors

Copper was one of the earliest materials used in power transmission due to its excellent electrical conductivity. However, due to higher cost and weight, copper conductors are now rarely used in long-distance overhead transmission.

Still, copper remains relevant in special cases where space constraints or superior conductivity are required. When discussing historical types of transmission line conductors, copper holds significant importance.

Know more about types of faults in transmission lines

Advantages of copper conductors:

- Very low electrical resistance

- High durability

- Strong mechanical properties

Disadvantages include high cost and heavier weight compared to aluminum-based conductors.

HTLS Conductors – High Temperature Low Sag

High Temperature Low Sag conductors are advanced conductors designed to operate at higher temperatures without excessive sag. These conductors use composite or special alloy cores instead of steel.

HTLS conductors are increasingly popular among modern types of transmission line conductors due to their ability to increase power transfer capacity without modifying existing towers.

Common HTLS types include:

- ACCC

- ACSS

- TACSR

Benefits of HTLS conductors:

- Higher current carrying capacity

- Minimal sag at high temperature

- Improved efficiency

- Ideal for line uprating projects

Know more about bus differential protection

Comparison of Common Types of Transmission Line Conductors

| Conductor Type | Core Material | Strength Level | Conductivity | Typical Application |

|---|---|---|---|---|

| AAC | None | Low | High | Short spans, urban areas |

| AAAC | Alloy | Medium | Medium-High | Coastal and industrial zones |

| ACSR | Steel | High | Medium | High-voltage long spans |

| ACAR | Alloy | Medium-High | High | Sub-transmission lines |

| Copper | None | High | Very High | Special applications |

| HTLS | Composite/Alloy | Very High | High | High-capacity upgrades |

This comparison highlights how different types of transmission line conductors serve different operational needs.

Factors Affecting Conductor Performance

Even among similar types of transmission line conductors, performance varies depending on external conditions. Temperature, wind pressure, ice loading, and pollution can significantly influence conductor behavior.

Important performance parameters include:

- Current carrying capacity

- Line losses

- Thermal expansion

- Corona discharge behavior

Engineers must evaluate these factors during transmission line design.

Know more about hvdc transmission

Environmental and Economic Considerations

Environmental impact and lifecycle cost are becoming critical in selecting among various types of transmission line conductors. Aluminum-based conductors are preferred due to recyclability and lower environmental footprint.

From an economic perspective, the initial cost, installation cost, and maintenance cost must be analyzed together rather than focusing only on material price.

Conclusion

Understanding the types of transmission line conductors is fundamental for designing reliable and efficient power transmission systems. From traditional AAC and ACSR to modern HTLS conductors, each option offers specific advantages based on electrical, mechanical, and environmental requirements.

Selecting the right conductor improves system performance, reduces losses, and ensures long-term reliability. As power demand increases and transmission corridors become limited, advanced conductor technologies will play an even more important role. A clear understanding of the types of transmission line conductors enables engineers and decision-makers to build stronger and more efficient power networks for the future.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub