Sizing Overloads for Motors: A Comprehensive Guide

Ensuring proper motor circuit protection is essential for the safe and efficient operation of electric motors. One critical aspect of this is sizing overloads for motors, which helps prevent overheating and potential damage. Overload relays and other protection devices are designed to guard motors from prolonged excessive currents that could lead to burnout or failure.

This detailed article explore the principles and technical details of motor overload protection, best practices for sizing overloads, and how this aligns with broader motor circuit protection systems. This guide is designed to help you understand the essentials of motor overloads while incorporating industry-relevant insights.

Table of Contents

Table of Contents

What Is an Overload Relay?

An overload relay is a protective device that safeguards motors from damage caused by excessive currents. When a motor operates beyond its rated capacity, it generates heat that can compromise insulation and mechanical integrity. Overload relays detect this condition and disconnect the motor to prevent damage.

There are various types of overload relays, including:

- Thermal overload relays: These use temperature-sensitive elements to detect excessive heat.

- Electronic overload relays: These rely on sensors to measure current and provide precise protection.

You can recognize these devices in circuit diagrams through the thermal overload relay symbol, commonly used in electrical schematics.

Importance of Sizing Overloads for Motors

Sizing overloads for motors involves selecting a relay or protection device that matches the motor’s rated current and operational characteristics. Proper sizing is essential for the following reasons:

- Preventing nuisance tripping: Overload protection should not trip unnecessarily during normal operations.

- Ensuring adequate protection: Undersized or oversized relays can lead to ineffective protection, risking motor failure.

- Complying with standards: Proper sizing adheres to guidelines like NEC (National Electrical Code) and IEC standards.

Motor overload sizing depends on the full-load current (FLC) of the motor, its service factor, and environmental conditions.

Steps for Sizing Overloads for Motors

To size an overload relay correctly, follow these steps:

1. Determine the Full-Load Current (FLC)

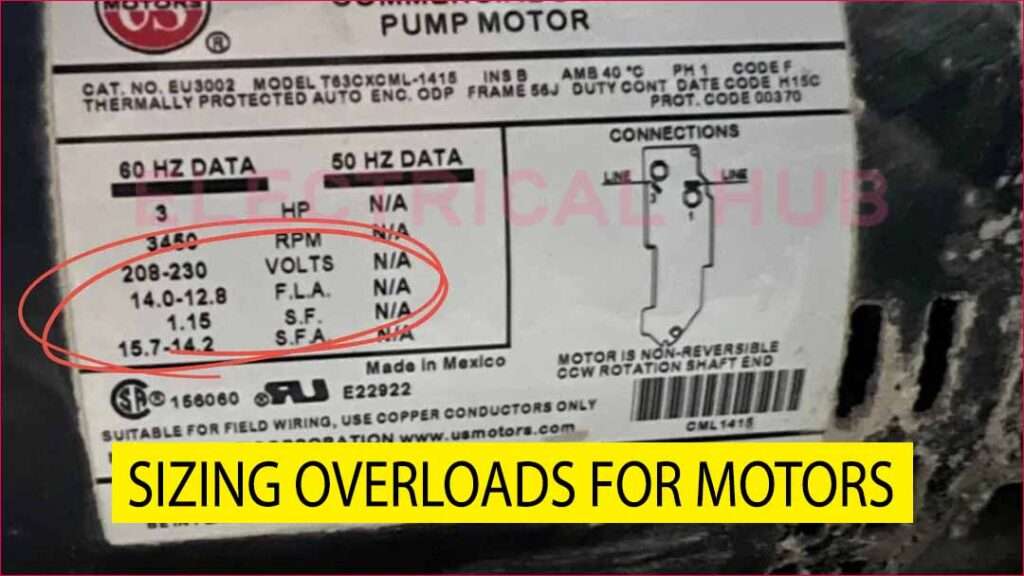

The motor’s FLC is typically listed on its nameplate. This value represents the current the motor draws when operating at its rated load and voltage.

2. Apply the Service Factor

The service factor (SF) accounts for the motor’s ability to operate above its rated load. For example, a motor with an SF of 1.15 can handle 15% more load than its rated capacity. Multiply the FLC by the service factor to determine the adjusted current.

3. Select the Overload Relay Setting

Most standards recommend setting the overload relay at 115% to 125% of the motor’s FLC. This ensures the motor can handle temporary surges without tripping while providing protection against sustained overloading.

4. Consider Environmental Factors

Environmental conditions such as temperature and altitude can affect motor performance. Adjust the overload settings to account for these factors when necessary.

Motor Circuit Protection Basics

In addition to overload relays, a comprehensive motor circuit protection system includes other components such as:

- Short-circuit protection devices: These protect against instantaneous high currents caused by faults.

- Fuses and circuit breakers: These are used alongside overload relays to provide layered protection.

A well-designed circuit protection system ensures seamless operation and enhances motor longevity.

Overload Protection in Motor Types

Different types of motors require specific overload protection strategies. Here’s a breakdown:

Induction Motors

Induction motors are widely used in industrial applications due to their simplicity and reliability. However, they are prone to overheating during prolonged overloads. Proper sizing of relays is critical to prevent issues. For more insights into induction motors, check out our detailed article on Induction Motor Interview.

Synchronous Motors

Synchronous motors require precise overload protection as they operate at constant speed. Incorrect sizing can lead to tripping or damage. To dive deeper into their operations, refer to our guide on Synchronous Motor Interview.

Stepper Motors

Although stepper motors are less prone to overloading due to their discrete operation, they still need protection to handle mechanical blockages. Learn more about stepper motors in our article on Stepper Motor Interview.

Common Mistakes in Sizing Motor Overloads

1. Ignoring the Service Factor

Failure to account for the service factor can lead to undersized overloads, compromising motor protection. Here is detailed guide on what is the service factor of a motor.

2. Incorrect Relay Adjustment

Improper relay settings can cause nuisance tripping or leave the motor unprotected during overload conditions.

3. Overlooking Environmental Conditions

Ignoring factors such as temperature fluctuations can result in inaccurate overload sizing.

Practical Example: Sizing Overloads for a 3-Phase Motor

Let’s consider a 3-phase induction motor with the following details:

- Full-Load Current (FLC): 50A

- Service Factor (SF): 1.15

Step 1: Calculate the Adjusted Current

Adjusted current = FLC × SF

Adjusted current = 50A × 1.15 = 57.5A

Step 2: Select the Overload Relay

Choose an overload relay rated for 115% to 125% of the FLC:

Relay setting = 57.5A × 1.15 = 66.13A (minimum setting)

Ensure the relay matches the environmental conditions and motor application.

Additional Resources for Motor Protection

To optimize motor performance and protection, explore these helpful tools and guides:

- Cable Size for Motor Calculator: A tool to determine appropriate cable sizes for motors.

- Interview Questions on Motors: Essential questions for understanding motor protection and performance.

Conclusion

Sizing overloads for motors is a critical step in ensuring motor longevity, efficiency, and safety. By carefully considering factors like full-load current, service factor, and environmental conditions, you can select the right overload relay for your application. Combine this with a comprehensive motor circuit protection strategy to maximize reliability.

Related Posts:

- What is star delta starter

- Star Delta Starter Diagram with Timer

- Overload Setting for Motor

- Difference Between Star Delta and DOL Starter

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#SizingOverloads, #MotorOverloadProtection, #OverloadRelay, #MotorSafety, #ThermalOverloadRelay, #ElectricalEngineering, #MotorControl, #OverloadSizing, #IndustrialMotors, #MotorProtection, #MotorEfficiency, #ThermalProtection, #OverloadRelayBasics, #MotorStarter, #EngineeringTips