OSHA Electrical Safety Standard 1910 – Workplace Electrical Safety | Safety Experts

Understanding electrical safety is essential for every workplace. The OSHA Electrical Safety Standard 1910 provides the foundation employers must follow to protect workers from electrical hazards. This standard guides companies on safe practices, equipment requirements, and preventive actions. Many organizations still struggle to apply these rules consistently. That is why knowing how each part of the standard works can reduce accidents and improve compliance.

Electrical incidents remain one of the top workplace hazards. Most events happen because of poor maintenance, unsafe environments, or lack of training. The OSHA Electrical Safety Standard 1910 helps companies build a safe system that prevents injuries. It also reduces downtime, equipment failure, and legal issues. When implemented correctly, it supports a culture of safe work that protects every employee.

What OSHA Electrical Safety Standard 1910 Covers

The OSHA Electrical Safety Standard 1910 covers almost every aspect of electrical safety. It includes installation requirements, safe work practices, equipment maintenance, and protection systems. The purpose is to eliminate risks caused by shock, arc flash, arc blast, and electrical fire.

Get complete information about iec standard for busbar sizing

This standard applies to factories, warehouses, commercial buildings, and construction-related maintenance work. It guides employers on how to reduce exposure to energized parts and manage all electrical systems in a safe condition.

Below is a simple table highlighting the core areas of the standard:

Key Elements of OSHA Electrical Safety Standard 1910

| Area | Description |

|---|---|

| Electrical installations | Safe design and wiring methods |

| Work practices | Procedures for energized and de-energized work |

| Maintenance requirements | Inspection and upkeep of electrical systems |

| Protective equipment | PPE for shock and arc flash protection |

| Hazard identification | Assessment of electrical risks |

| Employee training | Skills and awareness for electrical safety |

These elements work together to ensure that electrical operations remain controlled, safe, and compliant with federal regulations.

Read in detail about transformer manufacturers in egypt

Importance of OSHA Electrical Safety Standard 1910 in the Workplace

The OSHA Electrical Safety Standard 1910 is important because it reduces accidents caused by exposed wiring, faulty equipment, or unsafe work habits. Electrical hazards can cause burns, shocks, and fatal injuries. A single arc flash can reach temperatures hotter than the sun. That is why workplaces must never ignore preventive actions.

This standard also helps employers avoid heavy fines. OSHA penalties increase every year, and repeated violations can cost thousands of dollars. Following the standard gives confidence that the workplace is safe, and employees appreciate a well-managed environment.

Another advantage is the improvement of system reliability. Well-maintained equipment reduces downtime and ensures continuous operations. It lowers repair costs and helps companies run more efficiently. Find out more about iec 61439 busbar clearance

General Requirements under OSHA Electrical Safety Standard 1910

The standard lists several general requirements employers must fulfill. These apply to all electrical systems and work environments.

Safe electrical installations

All wiring must follow approved methods. Equipment must be installed in a way that prevents physical damage. Rooms with electrical equipment must remain clean, dry, and well-lit. The standard also requires proper labeling of disconnect switches and panels.

Safe work practices

Workers must avoid contact with energized parts unless necessary. If equipment can be de-energized, it must be turned off and locked out. Insulating tools, safety gloves, and barriers must be used when exposure is unavoidable.

Hazard identification

Employers must evaluate every electrical system for risk. This includes checking for exposed conductors, damaged cables, overloaded circuits, and malfunctioning equipment. Regular inspections are required. Discover everything about cable bending radius iec standard

Maintenance and testing

Equipment must be kept in good condition. Testing ensures that breakers, switches, relays, and protection devices work properly. Workers must document inspections and repairs.

Employee training

Employees must understand hazards, safe techniques, and emergency actions. Training must be updated when equipment changes or new work tasks are added.

Working with Energized and De-Energized Equipment

The OSHA Electrical Safety Standard 1910 clearly explains how to work safely with energized and de-energized equipment. Most tasks should be done on de-energized systems. Lockout Tagout is the primary method to ensure equipment stays off during maintenance.

When a system cannot be de-energized, strict controls apply. Workers must use insulated gloves, face shields, and arc-rated clothing. Barriers and signs must prevent accidental contact. Learn more about earthing cable size as per iec

Here is a comparison table for both types of work:

Energized vs. De-Energized Requirements

| Type of Work | Requirements |

|---|---|

| De-energized work | LOTO, verification of zero energy, grounding, insulated tools |

| Energized work | PPE, shock protection boundaries, arc flash labels, work permit, risk assessment |

Following these rules ensures no employee works under unsafe or unprotected conditions. Understand better about nec 430.32

Arc Flash Protection Requirements

Arc flash is one of the most dangerous events in electrical systems. The OSHA Electrical Safety Standard 1910 requires employers to identify arc flash hazards and apply suitable protection.

Arc flash labels must show the necessary PPE level, working distance, and incident energy. Workers must wear clothing that can withstand heat from potential arc blasts. Employers must also design systems to reduce arc flash energy, such as using fast-acting breakers or current-limiting fuses.

Key measures include:

- Using arc-rated gloves and suits

- Keeping unqualified personnel away from energized panels

- Maintaining equipment to reduce faults

- Providing updated arc flash studies

These actions significantly reduce the risk of burns and severe injuries.

Read in detail about iec 61439 busbar calculation

Electrical Safety Training Requirements

Training is one of the strongest parts of the OSHA Electrical Safety Standard 1910. Workers must receive instruction based on their job roles. Qualified workers need advanced training on live systems, voltage testing, and troubleshooting. Unqualified workers only receive awareness training to avoid contact with hazards.

Training must be simple, practical, and focused on real situations. Topics include shock prevention, lockout procedures, hazard recognition, emergency response, and safe use of tools and PPE.

Training must be documented and repeated at required intervals. Updated training is essential when new technology or equipment enters the workplace.

Employer Responsibilities under OSHA Electrical Safety Standard 1910

Employers must ensure the workplace is safe at all times. Their responsibilities include:

- Providing PPE for electrical work

- Conducting periodic risk assessments

- Correcting damaged equipment

- Ensuring panels and switches remain accessible

- Maintaining clear labeling and documentation

- Updating training programs

Employers must also foster a culture where safety is always a priority. Workers must feel confident reporting hazards without fear.

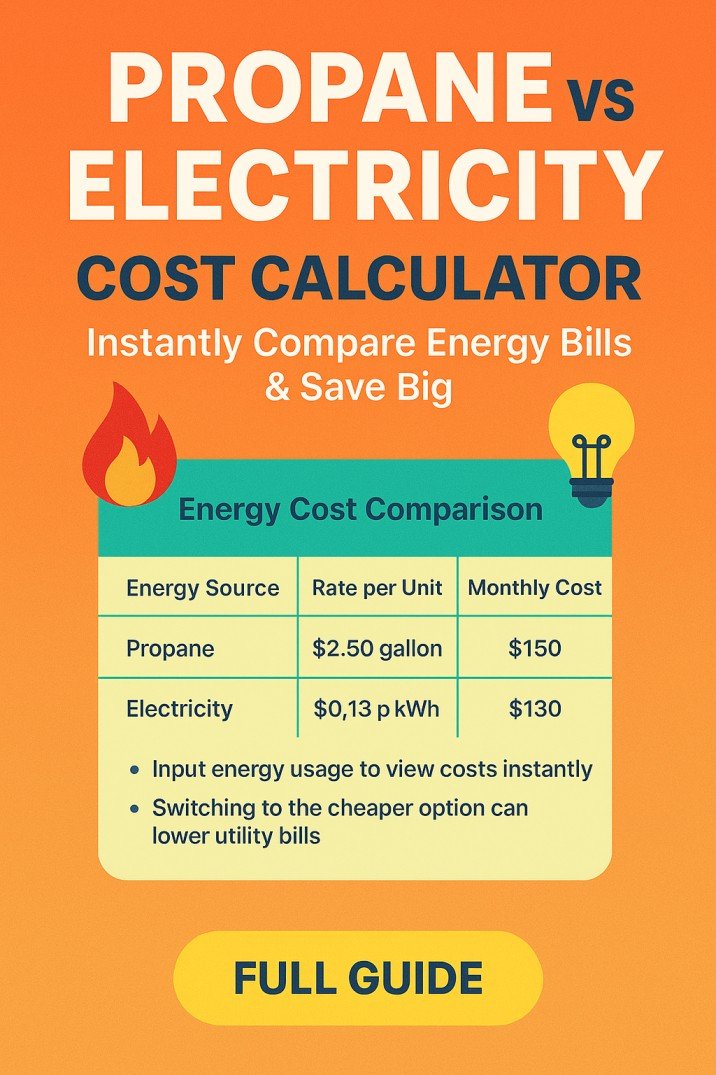

Use our online tool electricity load calculator in kw for home

How OSHA Electrical Safety Standard 1910 Improves Workplace Efficiency

The standard does more than prevent accidents. It also improves efficiency. Safe equipment lasts longer. Proper installations reduce energy waste. Well-trained workers make fewer mistakes. Consistent inspection prevents sudden failures. Altogether, these benefits create a workplace that runs smoothly.

Electrical safety also boosts productivity. Workers feel more secure and focused when they know the environment is safe. This enhances morale and reduces stress.

Final Thoughts

The OSHA Electrical Safety Standard 1910 remains one of the most important sets of rules for workplace electrical safety. It protects workers from electric shock, arc flash, and fire. It guides employers on safe installations, proper maintenance, and effective training. When followed correctly, it builds a reliable and compliant system.

Explore details on iec 61508 functional safety

Every company should review this standard regularly. Applying it fully ensures safer operations and better performance. Electrical safety is not optional. It is a long-term investment that protects both people and property.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#OSHAElectricalSafetyStandard1910, #ElectricalSafety, #WorkplaceSafety, #OSHACompliance, #SafetyStandards, #IndustrialSafety, #EmployeeProtection, #ElectricalHazards, #SafetyTraining, #OSHA1910