NEC 250.66 Table Size of Grounding Electrode Conductor: Best Guide

When it comes to electrical systems, safety is paramount. One of the most important safety measures in electrical installations is proper grounding, which helps prevent electrical hazards such as electrical shocks, fires, and equipment damage. The NEC 250.66 Table Size of Alternating-Current Grounding Electrode Conductor is a critical part of this safety protocol. In this article, we will explore the significance of NEC 250.66 table, how it relates to the sizing of alternating-current grounding electrode conductors, and how to ensure compliance with these standards.

Table of Contents

What is NEC 250.66?

The National Electrical Code (NEC) is a comprehensive set of guidelines for electrical installations in the United States. Among its various sections, NEC 250.66 specifically addresses the required size of grounding electrode conductors (GECs) for alternating-current (AC) systems. Grounding electrode conductors are used to connect the electrical system to a ground rod, plate, or other conductive materials to ensure the safe dissipation of electrical faults.

The purpose of NEC 250.66 is to provide a standard that ensures the grounding system is properly sized to handle fault currents without posing risks to human safety, equipment, or the electrical system itself. It helps to prevent excessive heating or damage to conductors, providing a path for electrical current to flow safely into the ground.

Know more about nec article 220

Why is Sizing Grounding Electrode Conductors Important?

Properly sized grounding electrode conductors are essential for the effective functioning of an electrical grounding system. Here are some of the reasons why proper sizing is important:

Prevents Overheating: If the grounding electrode conductor is too small, it can overheat during fault conditions, potentially causing damage to the conductor and creating fire hazards.

Ensures Fault Current Dissipation: The conductor must be large enough to carry the fault current to the ground without significant voltage drop, ensuring that all fault currents are properly dissipated.

Reduces Risk of Electric Shock: An adequately sized grounding system provides a safe path for fault currents to flow into the earth, reducing the risk of electric shock to people and animals.

Protects Equipment: Proper sizing of the grounding conductor helps ensure that connected equipment is protected from electrical surges and other power disturbances.

Know More about Grounding Cable Size as Per NEC

Understanding the NEC 250.66 Table Size Requirements

Factors Affecting Conductor Sizing

NEC 250.66 provides a table that specifies the size of the alternating-current grounding electrode conductor based on the size of the largest ungrounded service-entrance conductor. This is a critical consideration because the size of the grounding electrode conductor needs to correspond with the size of the largest conductor carrying current in the system. The table ensures that the grounding conductor is capable of safely handling fault currents that may occur.

The table considers several key factors, including:

Service-Entrance Conductor Size: This is the most significant factor in determining the size of the grounding electrode conductor. A larger service-entrance conductor requires a larger grounding conductor to handle potential fault currents.

Grounding Electrode Type: Different grounding electrodes have varying capacities to safely dissipate electrical energy. The type of electrode used will also influence the size of the grounding electrode conductor.

Know More about 3 Phase Motor Cable Size Calculator

Environmental Conditions: In some cases, environmental factors such as soil resistivity or moisture content can impact the performance of a grounding system, necessitating adjustments to the conductor size.

NEC 250.66 Table

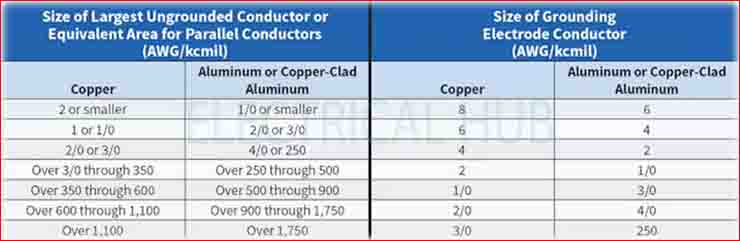

Below is a comprehensive table based on the NEC 250.66 Table for the Size of Alternating-Current Grounding Electrode Conductor. This table provides the grounding electrode conductor sizes for both copper and aluminum, depending on the size of the service-entrance conductor:

| Size of Largest Ungrounded Service-Entrance Conductor (AWG or kcmil) | Required Copper Grounding Electrode Conductor Size (AWG or kcmil) | Required Aluminum Grounding Electrode Conductor Size (AWG or kcmil) |

|---|---|---|

| 2 AWG or smaller | 8 AWG | 6 AWG |

| 1 AWG to 1/0 AWG | 6 AWG | 4 AWG |

| 2/0 AWG to 3/0 AWG | 4 AWG | 2 AWG |

| Over 3/0 AWG to 350 kcmil | 2 AWG | 1/0 AWG |

| Over 350 kcmil to 600 kcmil | 1/0 AWG | 3/0 AWG |

| Over 600 kcmil to 1100 kcmil | 2/0 AWG | 4/0 AWG |

| Over 1100 kcmil | 3/0 AWG | 250 kcmil |

Service-Entrance Conductor Size: The first column lists the size of the largest ungrounded conductor in the system. As this size increases, the size of the grounding electrode conductor also increases to safely handle potential fault currents.

Copper Grounding Electrode Conductor: The second column provides the required size of the grounding electrode conductor if copper is used. Copper conductors are more conductive, which is why they are often smaller than their aluminum counterparts for the same current-carrying capacity.

Know More about NEC Article 430.32

Aluminum Grounding Electrode Conductor: The third column lists the required size if aluminum conductors are used. Aluminum conductors generally require a larger size compared to copper due to their lower conductivity.

You can find the similar details in below image on NEC 250.66 Table for the Size of Alternating-Current Grounding Electrode Conductor.

This table is a practical reference for electrical installations to ensure compliance with NEC 250.66 and maintain safe and efficient grounding systems.

How to Read the NEC 250.66 Table

The NEC 250.66 table lists conductor sizes in both American Wire Gauge (AWG) and kcmil for different service-entrance conductor sizes. The table is divided into various ranges, allowing you to select the appropriate size for your specific application. Here’s how you can read the table:

Identify the Size of the Largest Ungrounded Conductor: The table starts by listing service-entrance conductor sizes, ranging from 2 AWG to larger sizes.

Determine the Corresponding Grounding Electrode Conductor Size: For each size of the service-entrance conductor, there is a corresponding size for the grounding electrode conductor. This is based on the maximum expected fault current and the ability of the conductor to safely handle this current.

Know More about Voltage Drop on Resistor Calculator

Use of Copper or Aluminum Conductors: The table provides conductor sizes for both copper and aluminum conductors. Copper has a higher conductivity, so smaller copper conductors may be used compared to aluminum for the same fault current capacity.

Examples from NEC 250.66 Table

- If you have a service-entrance conductor of 1/0 AWG copper, the grounding electrode conductor must be at least 8 AWG copper or 6 AWG aluminum.

- For a 250 kcmil aluminum service-entrance conductor, you would need a 2/0 AWG copper or 2 AWG aluminum grounding electrode conductor.

- For larger systems, such as a 2000 kcmil copper service conductor, a 500 kcmil copper grounding conductor is required.

NEC 250.66 Compliance and Grounding Methods

To ensure compliance with NEC 250.66, grounding electrode conductors must be installed in accordance with the size specified in the table. Additionally, grounding electrodes must be properly bonded to the electrical system to provide an effective path for fault current. Here are some key considerations when implementing a grounding system:

Connection to Grounding Electrode: The grounding electrode conductor must be connected securely to the grounding electrode, such as a ground rod or ground plate, to ensure effective current dissipation.

Bonding: Grounding conductors should be properly bonded to all conductive parts of the electrical system, including panels, equipment, and enclosures, to maintain a safe path for fault currents.

Inspections and Testing: After installation, the grounding system should be thoroughly inspected and tested to ensure compliance with NEC standards and to verify that it performs as expected under fault conditions.

Conclusion

The NEC 250.66 Table Size of Alternating-Current Grounding Electrode Conductor plays a crucial role in ensuring the safety and effectiveness of electrical grounding systems. By following the guidelines and properly sizing the grounding electrode conductor according to the service-entrance conductor size, electrical systems can be protected from faults, overheating, and other hazards.

When designing and installing electrical systems, always refer to the NEC for the most up-to-date standards, and consult with a licensed professional to ensure that your system is safe and compliant. A well-designed grounding system is essential for minimizing electrical risks, protecting people, equipment, and property, and ensuring the longevity of the electrical system.

Subscribe our Newsletter to get the latest updates in Electrical Engineering.

Worth Read Posts

#NEC25066, #GroundingElectrodes, #ElectricalCode, #NECTable25066, #ElectricalStandards, #ElectricalSafety, #NECCompliance, #GroundingConductors, #CodeCompliance, #ElectriciansGuide, #GroundingAndBonding, #ElectricalInstallation, #NECStandards, #ElectricalGrounding, #Table25066