IEC Standard for Nickel Cadmium Battery Explained: Ratings, Safety Rules, and Compliance Guide

The IEC standard for nickel cadmium battery plays a critical role in how industrial, utility, and backup power systems are designed, tested, and maintained worldwide. Nickel cadmium batteries are still widely used in substations, power plants, railway signaling, emergency lighting, and telecom systems because of their reliability in harsh environments. However, their performance and safety depend heavily on strict compliance with international standards.

Table of Contents

This article explains the IEC standard for nickel cadmium battery in a practical, engineer-friendly way. It covers battery ratings, safety requirements, testing procedures, and compliance expectations. Whether you are a design engineer, maintenance professional, or project consultant, understanding these standards helps you avoid failures, improve system reliability, and meet regulatory requirements.

Overview of IEC Standards for Nickel Cadmium Batteries

The International Electrotechnical Commission publishes specific standards that define how nickel cadmium batteries should be manufactured, tested, installed, and maintained. The most commonly referenced IEC standard for nickel cadmium battery in stationary applications is IEC 60623. This standard applies mainly to vented nickel cadmium batteries used for standby and industrial duties.

Learn more about earthing cable size as per iec

IEC 60623 defines electrical ratings, mechanical construction, electrolyte characteristics, and performance verification. It ensures batteries from different manufacturers meet comparable technical benchmarks. For portable nickel cadmium cells, IEC 61951 is typically applied, but industrial power systems rely more on IEC 60623.

By following the IEC standard for nickel cadmium battery, engineers can ensure consistent capacity delivery, long service life, and predictable behavior under fault or emergency conditions.

Nickel Cadmium Battery Ratings as per IEC

Battery ratings under IEC standards are not arbitrary values. They are based on standardized discharge conditions, temperature limits, and end voltage criteria. This approach allows accurate comparison between different battery models.

The IEC standard for nickel cadmium battery specifies capacity ratings in ampere-hours at defined discharge times, such as 5-hour, 10-hour, or 20-hour rates. These ratings are measured at a reference temperature, usually 20°C.

Find out more about iec 61439 busbar clearance

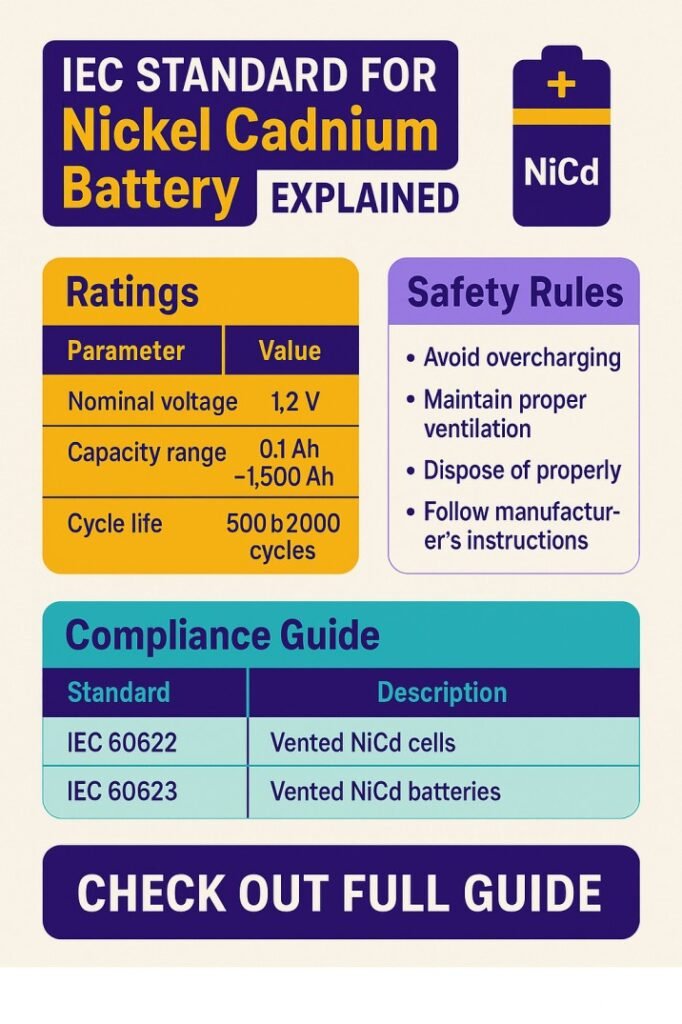

Table 1 shows typical IEC-defined rating parameters.

| Parameter | IEC Requirement | Practical Meaning |

|---|---|---|

| Nominal cell voltage | 1.2 V | Used for system voltage calculations |

| Rated capacity | Ah at specific discharge time | Determines backup duration |

| Reference temperature | 20°C | Ensures consistent test results |

| End discharge voltage | Defined per discharge rate | Protects battery health |

| Capacity tolerance | Minimum guaranteed value | Avoids undersized systems |

Engineers must select battery capacity based on load demand, autonomy time, aging factor, and temperature correction. The IEC standard for nickel cadmium battery ensures that declared ratings are conservative and repeatable.

Construction and Design Requirements

Nickel cadmium batteries covered under IEC standards are typically vented cells with robust internal construction. The standard specifies materials for plates, separators, electrolyte composition, and container strength.

Positive plates use nickel hydroxide, while negative plates contain cadmium compounds. The electrolyte is potassium hydroxide, which remains chemically stable during charge and discharge cycles. Unlike lead-acid batteries, the electrolyte does not degrade in normal operation.

Explore details on iec standard for underground cable laying

The IEC standard for nickel cadmium battery also defines clearances, creepage distances, and insulation requirements to prevent short circuits and leakage currents. Containers must withstand mechanical stress and electrolyte exposure over decades of service.

Safety Rules Defined by IEC

Safety is a core part of the IEC standard for nickel cadmium battery. These batteries are often installed in critical infrastructure where failure can cause major operational or safety risks.

IEC safety rules address ventilation, charging limits, electrolyte handling, and protection against short circuits. During charging, nickel cadmium batteries can emit hydrogen and oxygen gases. The standard requires adequate ventilation to prevent explosive gas accumulation.

Key safety provisions include:

- Maximum charge voltage limits to avoid overheating

- Clear labeling for polarity and electrolyte hazards

- Short-circuit withstand capability

- Mechanical stability during seismic or vibration conditions

Understand better about nec 430.32

Table 2 summarizes common safety-related IEC requirements.

| Safety Aspect | IEC Guideline | Purpose |

|---|---|---|

| Ventilation | Defined air flow per Ah | Prevents gas buildup |

| Charging voltage | Upper voltage limit per cell | Avoids thermal runaway |

| Insulation | Minimum resistance values | Reduces shock risk |

| Polarity marking | Permanent and visible | Prevents wiring errors |

| Spill containment | Electrolyte-resistant materials | Protects equipment and staff |

By following the IEC standard for nickel cadmium battery, organizations significantly reduce the risk of fire, explosion, and premature battery failure.

Performance Testing and Verification

Testing is another major area covered by the IEC standard for nickel cadmium battery. Manufacturers must prove that their products meet declared ratings and safety limits through standardized tests.

Capacity tests are performed at controlled temperature and discharge rates. The battery must deliver at least the minimum specified capacity before reaching the defined end voltage. High-rate discharge tests confirm performance during short-duration, high-current demands such as breaker tripping.

Dive deeper into instrument earthing iec standard

Endurance testing verifies long-term behavior through repeated charge and discharge cycles. Mechanical tests check resistance to vibration and shock, especially for railway and industrial installations.

Acceptance tests at site often follow IEC guidelines to confirm that batteries were not damaged during transport or storage. This ensures confidence before commissioning critical systems.

Installation and Commissioning Requirements

Proper installation is essential to maintain compliance with the IEC standard for nickel cadmium battery. The standard provides guidance on layout, spacing, and environmental conditions.

Battery rooms should maintain moderate temperature, controlled ventilation, and restricted access. Racks must support the battery weight and resist corrosion from alkaline electrolyte vapors.

During commissioning, initial charging procedures are defined to bring the battery to full capacity. Voltage, temperature, and electrolyte levels are monitored closely. Following IEC recommendations during commissioning helps achieve the expected service life.

Maintenance and Periodic Inspection

One advantage of nickel cadmium batteries is their low maintenance compared to other chemistries. Still, the IEC standard for nickel cadmium battery outlines periodic inspection practices.

Routine checks include visual inspection, voltage measurements, and electrolyte level verification. Capacity tests may be performed at defined intervals, especially for mission-critical applications.

Use our online tool electricity load calculator in kw for home

Maintenance records are important for compliance audits and reliability analysis. IEC-based maintenance ensures early detection of abnormal behavior, such as cell imbalance or connector corrosion.

Environmental and Compliance Considerations

Nickel cadmium batteries contain cadmium, which is classified as a hazardous material. The IEC standard for nickel cadmium battery works alongside environmental regulations to ensure safe handling and disposal.

Proper labeling, recycling, and end-of-life management are essential compliance steps. Many countries require documented recycling through approved facilities. Using IEC-compliant batteries simplifies regulatory approval and project documentation.

Compliance with IEC standards is often referenced in tender specifications, utility standards, and insurance requirements. Engineers who understand these rules can avoid costly redesigns or project delays.

Why IEC Compliance Matters in Real Projects

Ignoring the IEC standard for nickel cadmium battery can lead to undersized systems, safety hazards, and contractual disputes. In contrast, IEC compliance provides a common technical language between manufacturers, consultants, and end users.

Know more about What is Standard Voltage in USA? All You need to Know

It improves system reliability, ensures predictable backup performance, and supports long-term asset management. For substations, rail systems, and industrial plants, this consistency is not optional but essential.

Final Thoughts

The IEC standard for nickel cadmium battery is more than a technical document. It is a practical framework that ensures batteries perform safely and reliably over decades of service. From capacity ratings and safety rules to testing and maintenance, IEC guidelines support every stage of a battery’s lifecycle.

Engineers who apply the IEC standard for nickel cadmium battery correctly can design robust power systems, reduce operational risk, and meet international compliance expectations with confidence.

Know more about Phase to Phase Clearance as per IEC 61439: Best Guide

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard,#NickelCadmiumBattery,#NiCdBattery,#BatteryStandards,#IEC61951,#IndustrialBatteries,#BackupPower,#ElectricalStandards,#BatteryEngineering,#PowerSystems