IEC Standard for MV Cable Testing: Complete Acceptance, Routine & Type Test Guide

The IEC standard for MV cable testing is a critical reference for engineers, utilities, EPC contractors, and quality inspectors involved in medium voltage power systems. MV cables operate under demanding electrical and environmental conditions, and improper testing can lead to premature failures, safety hazards, and costly outages. This guide explains IEC-based testing requirements in a clear and practical way, covering acceptance tests, routine tests, and type tests used across industrial and utility projects.

Understanding the IEC standard for MV cable testing ensures compliance, reliability, and long-term system performance from manufacturing to commissioning.

Table of Contents

What Is MV Cable Testing According to IEC Standards

Medium voltage cables generally operate between 1 kV and 35 kV and are widely used in power distribution networks, substations, renewable energy plants, and industrial facilities. IEC standards define uniform test procedures to verify insulation integrity, conductor quality, sheath performance, and overall electrical strength.

The IEC standard for MV cable testing mainly focuses on XLPE and EPR insulated cables, ensuring they can withstand electrical, mechanical, and thermal stresses throughout their service life.

Know more about IEC Standard for XLPE Cables – Complete Guide to IEC 60502 and Electrical Cable Specifications

Key IEC standards involved include:

- IEC 60502-1 for MV power cables up to 30 kV

- IEC 60840 for cables above 30 kV up to 150 kV

- IEC 60228 for conductor requirements

- IEC 60229 for sheath testing

These standards collectively define how MV cables should be tested at different stages.

Know more about Earth Fault Relay Testing Procedure

Purpose of IEC-Based MV Cable Testing

The primary objective of MV cable testing under IEC guidelines is to detect defects early and confirm design suitability. Testing is not limited to voltage withstand checks but also includes mechanical, thermal, and material verification.

The IEC standard for MV cable testing helps achieve the following:

- Ensure insulation quality and uniformity

- Verify conductor resistance and dimensions

- Detect manufacturing defects

- Confirm compliance before energization

- Reduce long-term operational risks

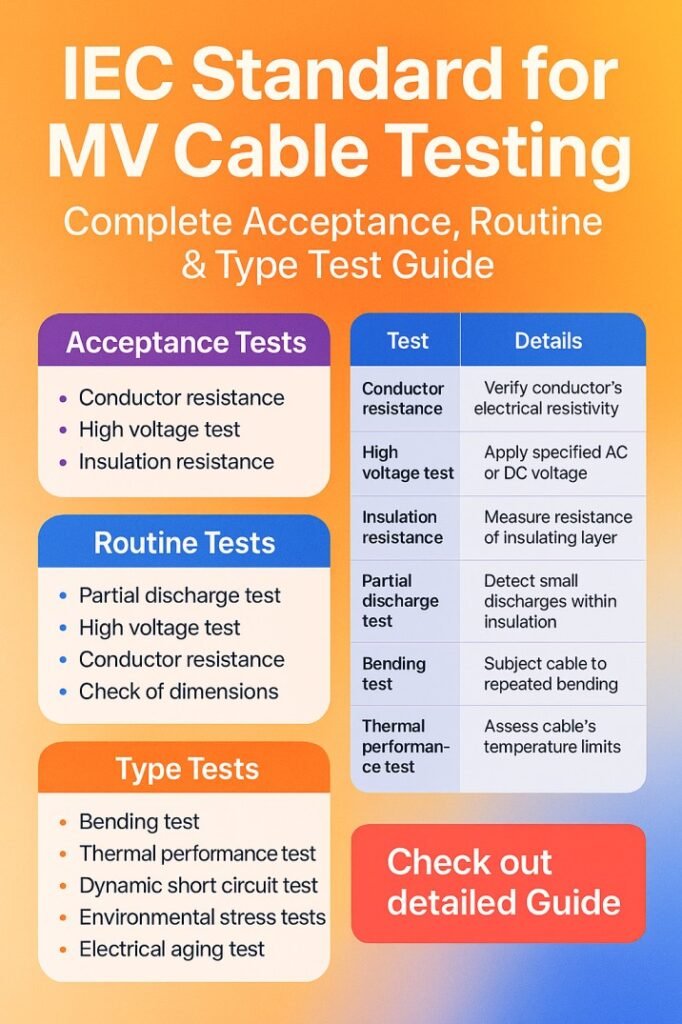

Classification of MV Cable Tests Under IEC

IEC divides MV cable tests into three main categories based on when and why they are performed. Each category serves a distinct purpose and follows defined procedures.

Know more about IEC Standard for Busbar Clearance

Overview of IEC MV Cable Test Categories

| Test Category | Purpose | Performed At |

|---|---|---|

| Routine Tests | Quality check on every cable length | Manufacturer |

| Type Tests | Design and material validation | Once per design |

| Acceptance Tests | Verification before commissioning | Site or factory |

This classification is central to the IEC standard for MV cable testing framework.

Routine Tests as Per IEC Standard

Routine tests are mandatory for every manufactured cable length. These tests ensure consistency and basic electrical safety.

Common Routine Tests for MV Cables

- Conductor resistance measurement

- AC voltage test on insulation

- Partial discharge test

- Spark test on outer sheath

Routine tests are non-negotiable under the IEC standard for MV cable testing, as they confirm that each delivered cable meets minimum electrical requirements.

Use our online tool Creepage Distance Calculator – Calculate Safe Insulation & Clearance for PCB and High Voltage Design

Typical Routine Test Parameters

| Test Name | IEC Reference | Typical Values |

|---|---|---|

| Conductor Resistance | IEC 60228 | As per class and size |

| AC Voltage Test | IEC 60502-1 | 2.5U₀ for 5 minutes |

| Partial Discharge | IEC 60502-1 | ≤ 5 pC |

Type Tests for MV Cables Under IEC

Type tests validate the cable design, insulation system, and materials. These tests are usually performed once unless the design or material changes.

The IEC standard for MV cable testing defines type tests as more severe and comprehensive than routine tests.

Know more about IEC Standards for Transformer Testing – Complete Guide to IEC 60076 and Testing Procedures

Major Type Tests Included

- Bending test followed by voltage test

- Heating cycle voltage test

- Impulse voltage withstand test

- Short-circuit test

- Mechanical impact test

These tests simulate real-life operating stresses and confirm long-term reliability.

Example Type Test Requirements

| Type Test | Purpose |

|---|---|

| Heating Cycle Test | Verify thermal endurance |

| Impulse Voltage Test | Confirm surge withstand capability |

| Short Circuit Test | Check conductor and insulation stability |

Acceptance Tests Before Energization

Acceptance tests are performed after installation but before the cable is energized. They confirm that handling, laying, and jointing have not damaged the cable.

Under the IEC standard for MV cable testing, acceptance tests are essential for site quality assurance.

Know more about Phase to Phase Clearance as per IEC 61439: Best Guide

Common Acceptance Tests

- Insulation resistance test

- AC withstand test

- Very Low Frequency (VLF) test

- Sheath integrity test

VLF testing is widely used for MV cables due to its practicality for long cable lengths.

Typical Acceptance Test Voltage Levels

| Cable Rated Voltage | VLF Test Voltage | Duration |

|---|---|---|

| 6.6 kV | 13 kV | 30 minutes |

| 11 kV | 22 kV | 30 minutes |

| 33 kV | 52 kV | 30 minutes |

These values align with the IEC standard for MV cable testing and utility best practices.

Uncover insights on iec standard for lighting lux level

Partial Discharge Testing in IEC MV Standards

Partial discharge testing is one of the most critical aspects of MV cable evaluation. It detects insulation defects that may not cause immediate failure but can grow over time.

The IEC standard for MV cable testing specifies PD limits and test setups to ensure consistent results.

Benefits of PD Testing

- Early fault detection

- Improved asset reliability

- Reduced maintenance costs

- Enhanced system safety

PD testing is mandatory during routine and type testing and is increasingly recommended during acceptance testing.

Know more about IEC Standard for Relay Coordination – Complete Guide to Protection and Coordination Studies

Sheath and Oversheath Tests

Cable sheaths protect against moisture ingress and mechanical damage. IEC standards define strict sheath testing methods.

Sheath Tests Include

- DC voltage sheath test

- Spark test for non-metallic sheaths

- Visual and dimensional inspection

Failure of sheath tests can lead to insulation degradation even if electrical tests pass, which is why the IEC standard for MV cable testing emphasizes sheath integrity.

Read in detail about iec 61439 busbar calculation

Common Mistakes During MV Cable Testing

Despite clear guidelines, errors still occur during testing. Awareness helps prevent non-compliance.

- Applying incorrect test voltage levels

- Ignoring temperature correction for resistance tests

- Skipping PD measurements

- Confusing IEC and IEEE test limits

- Poor documentation of results

Strict adherence to the IEC standard for MV cable testing eliminates these risks.

Know more about IEC Standard for Vibration Testing – IEC 60068 Explained with Procedures and Requirements

Documentation and Test Reporting

IEC standards require detailed test records. Proper documentation is essential for audits, warranty claims, and future maintenance.

A Good MV Cable Test Report Includes

- Cable identification details

- Test equipment calibration status

- Test voltages and durations

- Measured values and limits

- Pass or fail conclusion

Get complete information about iec standard for busbar sizing

Accurate reporting strengthens compliance with the IEC standard for MV cable testing and supports asset management strategies.

Why IEC MV Cable Testing Matters in Modern Power Systems

As power networks grow more complex, cable failures become more costly. IEC-compliant testing ensures reliability, safety, and long-term performance.

The IEC standard for MV cable testing provides a globally accepted framework that aligns manufacturers, contractors, and utilities on quality expectations. It reduces disputes, improves system uptime, and protects investments.

Final Thoughts

Medium voltage cables are critical assets, and their testing should never be treated as a formality. By following the IEC standard for MV cable testing, engineers can confidently verify cable quality from factory to site. Routine tests ensure manufacturing consistency, type tests validate design strength, and acceptance tests confirm installation integrity.

Explore details on iec standard for underground cable laying

A disciplined IEC-based testing approach not only meets regulatory requirements but also delivers safer and more reliable power systems for decades to come.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard,MVCableTesting,IECStandardForMVCableTesting,MediumVoltageCables,ElectricalTestingStandards,PowerCableTesting,HighVoltageTesting,IEC60502,CableTestingGuide,ElectricalEngineering