IEC 61000 Standards: A Comprehensive Guide

In today’s interconnected world, electromagnetic compatibility (EMC) plays a crucial role in ensuring the reliable operation of electrical and electronic equipment. At the forefront of EMC regulations are the IEC 61000 standards, a series of guidelines that set the benchmark for electromagnetic compatibility across various industries. This article delves into the intricacies of these standards, their significance, and their impact on modern technology.

The Importance of IEC 61000 Standards in EMC

Electromagnetic compatibility is not just a buzzword; it’s a necessity in our technology-driven society. The IEC 61000 standards serve as the cornerstone for achieving this compatibility. These standards, developed by the International Electrotechnical Commission (IEC), provide a framework for manufacturers, designers, and engineers to ensure that their products can function as intended in their electromagnetic environment without causing unacceptable interference.

IEC 61000-6 Standards, developed by the International Electrotechnical Commission (IEC), are a set of international standards that address electromagnetic compatibility (EMC). In essence, EMC ensures that electronic and electrical systems can operate effectively in their designated environments without causing or succumbing to interference.

The IEC 61000 series covers a wide range of EMC aspects, from general principles to specific test methods and limits. One of the most critical subsets of this series is the IEC 61000-6 family, which focuses on generic standards for immunity and emissions in various environments.

Breaking Down the IEC 61000-6 Series

The IEC 61000-6 series, also known as the generic standards, is particularly noteworthy. These standards provide a set of essential requirements and test procedures that apply to a broad range of products. Let’s explore some key components of this series:

IEC 61000-6-1 is the standard for immunity in residential, commercial, and light-industrial environments. It sets out the minimum immunity requirements for equipment intended for use in these settings. This standard ensures that devices can withstand common electromagnetic disturbances without malfunction.

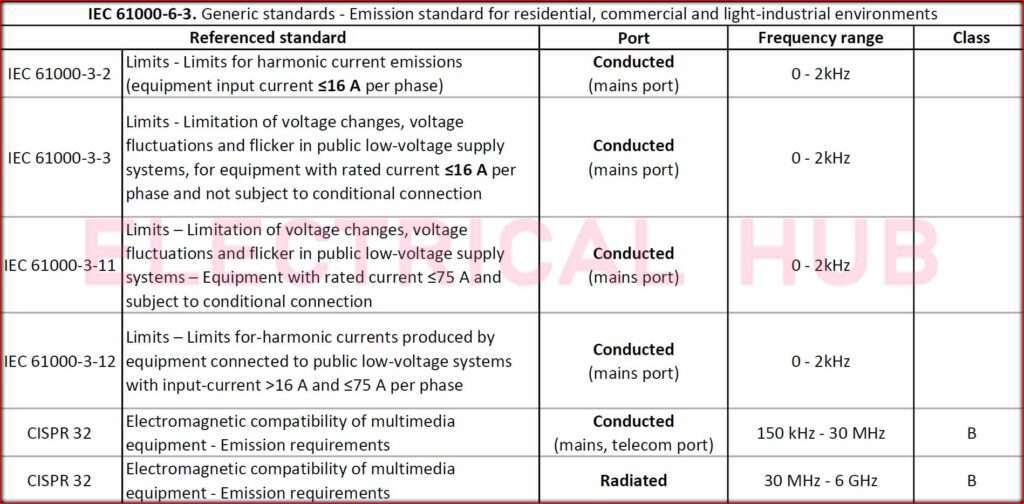

Complementing IEC 61000-6-1 is IEC 61000-6-3, which deals with emission standards for residential, commercial, and light-industrial environments. This standard defines the maximum allowable electromagnetic emissions from equipment, helping to prevent interference with other nearby devices.

For more demanding environments, we have IEC 61000-6-2. This standard specifies immunity requirements for equipment intended for use in industrial environments. Industrial settings often have higher levels of electromagnetic disturbances, necessitating more robust protection measures.

It’s worth noting that these standards are often adopted by regional bodies. For instance, in Europe, you might see references to EN 61000-6 or EN 61000-6-1. These are essentially the European adoptions of the IEC standards, ensuring consistency across the region.

Know More about Motor Overload Setting Table

Technical Details of IEC 61000 Standards

Diving deeper into the technical aspects, the IEC 61000 standards cover a diverse range of electromagnetic phenomena. These include conducted disturbances, radiated disturbances, electrostatic discharge (ESD), and power frequency magnetic fields, among others.

Each standard in the series provides specific test methods and limits for different types of disturbances. For example, IEC 61000-4-2 deals with electrostatic discharge immunity, while IEC 61000-4-3 covers radiated, radio-frequency, electromagnetic field immunity tests.

The 61000-6 subset, as mentioned earlier, provides generic standards that apply to a wide range of products. These standards specify the minimum immunity levels that equipment must meet to ensure reliable operation in their intended environment. They also define the maximum emission levels to prevent interference with other equipment.

One of the strengths of the IEC 61000 series is its comprehensive approach. It doesn’t just focus on one aspect of EMC but covers the entire spectrum from low-frequency phenomena to high-frequency disturbances. This holistic approach ensures that equipment is protected against a wide range of potential electromagnetic interferences.

Know More about Motor Wire Size Calculator

Global Adoption and Regional Variations

While the IEC 61000 standards are international, many countries and regions have adopted them into their own regulatory frameworks. For instance, in Australia and New Zealand, you might encounter AS/NZS 61000, which is based on the IEC standards but adapted for local conditions and requirements.

The European Union has widely adopted these standards, often prefixing them with “EN” (European Norm). So, you might see references to EN 61000-6-3 or EN 6100-6-3 (note the slight variation in numbering, which can sometimes occur). These adoptions ensure consistency across the EU market while aligning with international standards.

Impact on Product Design and Manufacturing

The IEC 61000 standards have a profound impact on product design and manufacturing processes. Engineers and designers must consider EMC requirements from the early stages of product development. This proactive approach not only ensures compliance but can also lead to more robust and reliable products.

For manufacturers, adhering to these standards often involves rigorous testing procedures. Products must undergo various EMC tests to demonstrate compliance with the relevant standards. These tests simulate real-world electromagnetic environments and disturbances to ensure that the equipment can function reliably under various conditions.

Know More about Grounding Cable Size as Per NEC

The standards also influence component selection and circuit design. Designers must choose components and implement design techniques that help achieve the required immunity and emission levels. This might involve using shielding, filtering, or other EMC mitigation techniques.

Challenges and Opportunities

While complying with IEC 61000 standards can be challenging, it also presents opportunities for innovation. Manufacturers who excel in EMC design often gain a competitive edge in the market. Their products are more likely to perform reliably in various electromagnetic environments, leading to increased customer satisfaction and brand reputation.

Moreover, as technology evolves, so do the standards. The IEC regularly reviews and updates its standards to keep pace with technological advancements. This ongoing process ensures that the standards remain relevant and effective in addressing new EMC challenges that arise with emerging technologies.

Major Objectives of IEC 61000-6 Standards

Focus on Industrial Environments

IEC 61000-6 Standards specifically concentrate on providing guidelines for immunity requirements and test methods for equipment utilized in industrial settings. Industrial environments pose challenges due to the presence of diverse electronic devices and the potential for electromagnetic interference from sources like power lines and motors.

Immunity Levels and Testing

The standard outlines the levels of immunity that equipment should withstand and prescribes testing methods to ensure compliance. The primary objective is to guarantee that equipment functions reliably even when exposed to common electromagnetic disturbances encountered in industrial environments.

Know More about Backup Generator Sizing Calculator

Importance for Manufacturers and Users

Adhering to standards like IEC 61000-6 Standards are critical for both manufacturers and users of industrial equipment. Compliance helps ensure that devices can operate effectively without being adversely affected by electromagnetic interference. Additionally, it minimizes the risk of causing interference to other equipment within the same environment.

Specific Applications of IEC 61000-6 Standards

IEC 61000-6-8: Light-Industrial Equipment

IEC 61000-6-8 is applicable to light-industrial equipment meeting specific usage restrictions. This includes equipment defined as professional, professionally installed and maintained, and not intended for residential use. Alternatively, IEC 61000-6-3 applies to electrical and electronic equipment intended for use in commercial and light-industrial locations that do not meet these restrictions.

Examples of applicable locations include retail outlets, business premises, areas of public entertainment, places of worship, outdoor locations, general public areas, hospitals, educational institutions, public traffic areas, railway stations, public areas of airports, and specific common areas of buildings like basements, control rooms, electrical service areas, workshops, laboratories, and service centers.

IEC 61000-6-1: General Equipment Emission Standards

IEC 61000-6-1 applies to equipment without dedicated product standards or emission standards. It covers equipment intended for operation in residential locations (indoors and outdoors) and commercial, public, and light-industrial locations.

Know More about 3 Phase Motor Cable Size Calculator

IEC 61000-6-2: Generic Immunity Levels for Industrial Environment

IEC 61000-6-2 is a generic standard for immunity in industrial environments, covering both indoor and outdoor settings. It applies to equipment without relevant dedicated product standards or product family emission standards.

IEC 61000-6-4: Generic Emission Limits for Industrial Environment

IEC 61000-6-4 is a generic standard for emissions in industrial environments, covering both indoor and outdoor settings. It applies to equipment not falling within the scope of IEC 61000-6-3 and lacks relevant dedicated product standards or product family emission standards.

IEC 61000-6-8: Emission Limits for Light-Industrial Environment

IEC 61000-6-8 is a generic standard for emissions in light-industrial environments, applying to light-industrial equipment meeting specific restrictions of use. If these restrictions are not met, IEC 61000-6-3 is applicable.

Conclusion

In conclusion, the IEC 61000 standards play a vital role in ensuring electromagnetic compatibility in our increasingly connected world. From the comprehensive IEC 61000 series to the specific requirements outlined in standards like IEC 61000-6-1 and IEC 61000-6-2, these guidelines provide a robust framework for EMC compliance.

As we continue to develop new technologies and push the boundaries of what’s possible, the importance of these standards will only grow. They serve not just as regulatory requirements but as enablers of innovation, ensuring that our devices can coexist harmoniously in the complex electromagnetic environments of the modern world.

Whether you’re a manufacturer, engineer, or simply a consumer of electronic products, understanding the basics of IEC 61000 standards can provide valuable insight into the invisible yet crucial world of electromagnetic compatibility. As we look to the future, these standards will undoubtedly continue to evolve, shaping the landscape of electronic design and ensuring the reliability of our increasingly connected devices.

1. What is IEC 61000-6?

IEC 61000-6 Standards is a series of international standards developed by the International Electrotechnical Commission (IEC) that addresses electromagnetic compatibility (EMC). It focuses on providing guidelines for immunity requirements and test methods for equipment used in various environments, with specific attention to industrial settings.

2. Why is EMC important in industrial environments?

Electromagnetic compatibility (EMC) is crucial in industrial environments to ensure that electronic and electrical equipment can function properly without causing or being affected by interference. Industrial settings often have a multitude of electronic devices, and EMC standards like IEC 61000-6 help prevent issues related to electromagnetic disturbances.

3. What does IEC 61000-6 cover?

IEC 61000-6 Standards cover generic standards for immunity and emission in different environments. It includes specific parts such as IEC 61000-6-1 (general emission standards), IEC 61000-6-2 (generic immunity levels for industrial environments), IEC 61000-6-3 (emission standards for residential, commercial, and light-industrial environments), IEC 61000-6-4 (emission limits for industrial environments), and IEC 61000-6-8 (emission limits for light-industrial environments).

4. What is the purpose of IEC 61000-6-2?

IEC 61000-6-2 is a generic standard for immunity in industrial environments. It specifies immunity levels and test methods for electronic and electrical equipment operating in these settings. The goal is to ensure that equipment remains reliable and operational in the presence of common electromagnetic disturbances encountered in industrial environments.

5. How does IEC 61000-6-8 differ from other parts of the series?

IEC 61000-6-8 specifically addresses emission limits for light-industrial environments. It applies to equipment defined as professional, professionally installed and maintained, and not intended for residential locations. If these criteria are not met, IEC 61000-6-3 applies to electrical and electronic equipment intended for use in commercial and light-industrial locations.

6. Who should adhere to IEC 61000-6 standards?

Manufacturers and users of electronic and electrical equipment, especially those operating in industrial environments, should adhere to IEC 61000-6 standards. Compliance ensures that equipment can function effectively without being adversely affected by electromagnetic interference, promoting overall system reliability.

7. Are there specific emission limits for industrial environments in IEC 61000-6 Standards?

Yes, IEC 61000-6-4 sets generic emission limits for industrial environments, covering both indoor and outdoor settings. It applies to equipment that does not fall within the scope of IEC 61000-6-3 and lacks relevant dedicated product standards or product family emission standards.

8. How can one determine the applicable part of IEC 61000-6 for their equipment?

The applicability depends on the type of equipment and the intended environment of use. Manufacturers should carefully review the definitions and criteria provided in each part of IEC 61000-6 to determine which standard is most relevant to their specific case.

9. What is the IEC 61000 standard?

The IEC 61000 standard addresses Electromagnetic Compatibility (EMC). It provides a series of guidelines and procedures for managing the effects of electromagnetic disturbances on electrical and electronic devices, ensuring that equipment can operate effectively without causing interference. It covers testing methods and performance limits related to emissions and immunity.

10. What is the difference between IEC 61000 and 61326?

IEC 61000 is a broader standard focused on EMC testing and limits, applicable to various industries and equipment.

IEC 61326 is specifically for EMC requirements for measurement, control, and laboratory equipment. It sets limits and test requirements for the immunity and emissions of devices used in these specialized fields.

11. What is the IEC standard for thermal shock test?

The IEC 60068-2-14 standard covers the thermal shock test. It provides guidelines for testing the ability of materials and products to withstand rapid temperature changes without damage, helping assess their durability under extreme conditions.

12. What is the difference between IEEE 519 1992 and IEC 61000 series standards?

IEEE 519-1992 focuses on harmonic control in electrical power systems, setting limits on the harmonic distortion in voltage and current to ensure system reliability and power quality.

The IEC 61000 series encompasses a wider range of EMC concerns, including immunity to electromagnetic disturbances and electromagnetic emissions. While both standards address electrical disturbances, IEEE 519 is more specific to harmonics, and IEC 61000 deals with broader EMC compliance.

13. What is IEC 61000-4-20:2022?

IEC 61000-4-20:2022 is a standard that outlines test methods for emission and immunity testing in reverberation chambers. It specifies the requirements for creating a uniform electromagnetic environment to test the effects of electromagnetic disturbances on devices.

14. What is IEC 61000-4-3:2006?

IEC 61000-4-3:2006 provides guidelines for radiated RF electromagnetic field immunity testing. It defines the test procedures for determining the immunity of electrical and electronic devices to radiated electromagnetic fields, covering frequencies from 80 MHz to 1 GHz and ensuring they function correctly when exposed to electromagnetic interference.

15. Enlist Common EMC Test Standards

IEC 61000-4-2: Electrostatic Discharge (ESD) immunity test

IEC 61000-4-3: Radiated RF electromagnetic field immunity test

IEC 61000-4-4: Electrical fast transient/burst immunity test

IEC 61000-4-5: Surge immunity test

IEC 61000-4-6: Conducted RF immunity test

IEC 61000-4-8: Power frequency magnetic field immunity test

IEC 61000-4-11: Voltage dips, short interruptions, and voltage variations immunity test

CISPR 11: EMC for industrial, scientific, and medical equipment

CISPR 22/32: EMC for information technology equipment

Worth Read Posts

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Reference

Design for Electromagnetic Compatibility

IEC 61000 Series Overview

International Electrotechnical Commission. (n.d.). Electromagnetic Compatibility (EMC) Standards – IEC 61000 series. Retrieved from IEC Official WebsiteElectromagnetic Compatibility Testing

IEEE Xplore. (n.d.). Introduction to Electromagnetic Compatibility and Testing for EMC – IEEE 519 and IEC 61000 Standards. Available on IEEE Xplore Digital LibraryThermal Shock Testing Standard (IEC 60068-2-14)

International Electrotechnical Commission. (2014). IEC 60068-2-14: Environmental Testing – Part 2-14: Tests – Test N: Change of Temperature.Comparison Between IEEE 519 and IEC 61000 Standards

Hartmann, D. (2010). Understanding Harmonics and the Differences Between IEEE 519 and IEC 61000-3-2/3 Standards. Electrical Engineering Journal, Vol. 23. Retrieved from ResearchGateIEC 61000-4-20:2022 – Reverberation Chamber Testing

International Electrotechnical Commission. (2022). IEC 61000-4-20:2022 – Electromagnetic Compatibility (EMC) – Part 4-20: Testing and measurement techniques – Reverberation chamber test methods.IEC 61000-4-3:2006 – RF Immunity Testing

International Electrotechnical Commission. (2006). IEC 61000-4-3: Radiated, radio-frequency, electromagnetic field immunity test.