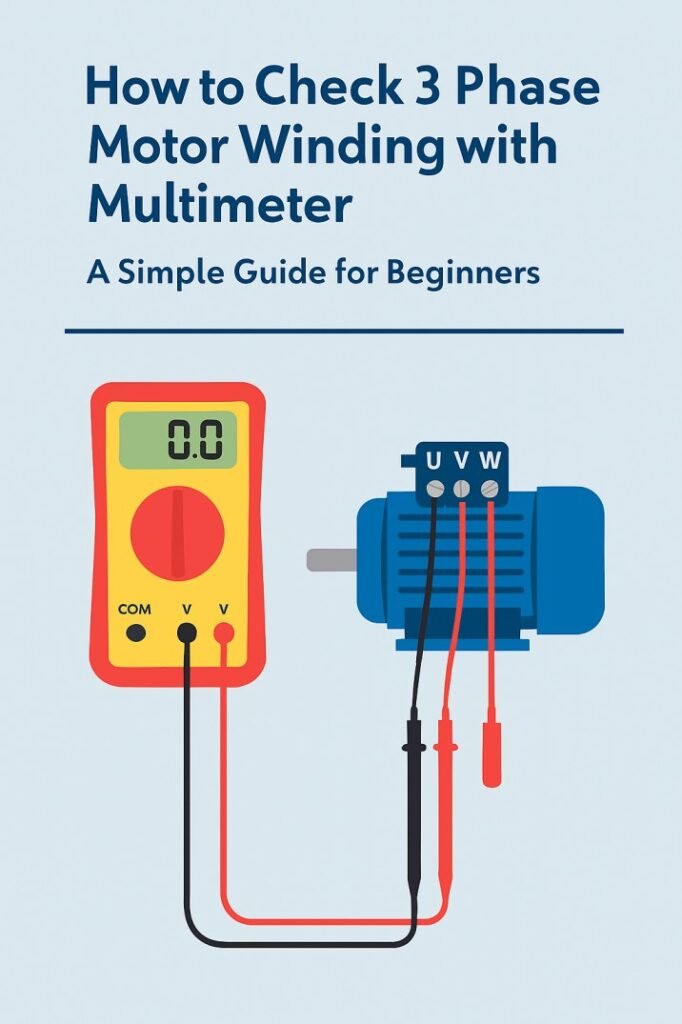

How to Check 3 Phase Motor Winding with Multimeter: A Simple Guide for Beginners

Learning how to check 3 phase motor winding with multimeter is essential for anyone handling industrial motors, workshops, or maintenance tasks. A faulty motor winding can cause overheating, uneven rotation, low torque, blown fuses, or complete motor failure. A simple multimeter test helps you identify winding imbalance, insulation breakdown, open circuits, and shorted turns before the motor reaches a critical failure point.

Table of Contents

Why Checking 3-Phase Motor Windings Is Important

A 3-phase motor depends on balanced and healthy windings. When one phase becomes weak or damaged, the motor loses its ability to rotate smoothly. It draws extra current and may even damage connected equipment. This is why technicians always check 3 phase motor winding with multimeter before installing or energizing any motor that has been in storage or transport.

Know more about VLF Testing vs Hipot: Best Guide on Key Differences and Applications

Regular checks prevent breakdowns. They also help you detect issues that cannot be seen from outside the motor body. Problems like overheating, moisture contamination, loose connections, or internal shorts often show up only when you test winding resistance and insulation.

Tools You Need for Testing

You only need a few basic tools to check 3 phase motor winding with multimeter.

| Tool | Purpose |

|---|---|

| Digital multimeter | Measure resistance, continuity, and insulation |

| Permanent marker | Label terminals for correct identification |

| Screwdriver | Open terminal box |

| Dry cloth | Clean dirty terminals |

| Safety gloves | Protect against electric shocks |

A multimeter with an ohms range is enough. If you have a megger, you can also check insulation resistance, but it is optional for basic testing.

Safety Rules Before Testing

Safety matters the most. Always disconnect the motor from power before you check 3 phase motor winding with multimeter. Even a small amount of residual voltage can be dangerous.

Follow these rules:

- Lockout the power supply

- Discharge capacitors

- Remove external wires

- Clean terminals

- Keep hands dry

- Work in proper lighting

Once you confirm the motor is safe to touch, you can proceed with the actual testing steps.

Use our online tool Electrical Insurance Premium Calculator – Estimate Your Electrical Coverage Cost Online

Identify the Motor Terminals

Every 3-phase motor has three main windings. These are usually marked as U1, V1, and W1 on one side and U2, V2, and W2 on the other. If the motor has only three leads, the internal connection may already be inside the winding.

To check 3 phase motor winding with multimeter, you must identify the right terminals. If markings are missing, use a marker and note each pair after confirming continuity.

Step 1: Continuity Test of Each Winding

The first test is continuity. It confirms whether each winding is complete and not open.

Steps:

- Set the multimeter to continuity or low ohms.

- Touch the probes across U1–U2.

- A beep or small resistance value means the winding is good.

- Repeat for V1–V2 and W1–W2.

If any pair shows “OL” or infinite resistance, that winding is open. At this stage, you have completed the first method to check 3 phase motor winding with multimeter.

Know more about Contact Resistance Test Acceptable Value for Breaker

Here is a simple reference table:

| Winding Pair | Expected Result |

|---|---|

| U1–U2 | Continuity / Low resistance |

| V1–V2 | Continuity / Low resistance |

| W1–W2 | Continuity / Low resistance |

Step 2: Compare Winding Resistance

The most important test when you check 3 phase motor winding with multimeter is resistance comparison.

All three windings must show nearly equal resistance. A big mismatch means one winding is shorted or partially damaged.

Steps:

- Set the meter to ohms.

- Measure U1–U2, V1–V2, and W1–W2.

- Note the values.

- Compare the differences.

Example:

| Winding | Resistance (Ohms) | Status |

|---|---|---|

| U1–U2 | 1.2 Ω | Normal |

| V1–V2 | 1.2 Ω | Normal |

| W1–W2 | 1.4 Ω | Slightly high |

A tolerance of ±10% is acceptable for most motors.

If one winding is too low, it may have a short in the coil. If too high, the coil may be damaged or overheated.

Know more about MCC Panel Design Guide – IEC Standards, Wiring Diagram, Cost, and Sizing Calculations (Excel Template)

Step 3: Test for Phase Balance

Phase balance means all three phases should be electrically identical.

This is the third method to check 3 phase motor winding with multimeter, and it helps you detect hidden problems.

If the resistance difference between the highest and lowest winding is more than 10%, the motor could run unevenly and overheat.

Balanced windings ensure smooth rotation, stable torque, and long motor life.

Step 4: Test for Short to Ground

This is a very important test. A short to ground can cause tripping, sparks, and coil burning.

You can still check 3 phase motor winding with multimeter if you do not have a megger.

Steps:

- Set the multimeter to the highest ohms range.

- Place one probe on the motor body.

- Place the other probe on U1, then on V1, then on W1.

- Repeat for U2, V2, and W2 if available.

Expected reading: Infinite resistance (OL)

Anything below that indicates insulation damage or moisture inside the winding.

Step 5: Identify Wrong Connections

If the motor was repaired earlier, the technician may have swapped the leads by mistake. This affects the motor rotation and performance.

When you check 3 phase motor winding with multimeter, you can quickly verify whether each winding pair belongs together. The meter will show continuity only for the correct pair.

Use our online tool Motor Overload Setting Calculator for Single and Three Phase Motors

Step 6: Testing a Motor with Six Terminals

For motors with six terminals, the steps remain the same but require extra attention.

You will test:

- U1–U2

- V1–V2

- W1–W2

After confirming that, check:

- Resistance match

- No ground leakage

- No cross continuity

This helps you fully check 3 phase motor winding with multimeter without missing hidden issues.

Table: Quick Fault Diagnosis Guide

| Test Result | Probable Issue | Action |

|---|---|---|

| No continuity | Open winding | Rewind / Replace |

| Very low resistance | Internal short | Rewind |

| High resistance | Weak coil | Check overheating history |

| Ground leakage | Damaged insulation | Dry or rewind |

| Imbalanced readings | Partial failure | Inspect motor |

Know more about 3 Phase Motor Winding Resistance Chart & Testing

Extra Tips for Accurate Testing

- Test when the motor is cool

- Clean dusty terminals

- Label wires to avoid confusion

- If readings fluctuate, clean the probes

- Repeat the measurement twice for accuracy

When you consistently check 3 phase motor winding with multimeter, you develop the skill to identify faults even before they become serious.

Final Thoughts

Knowing how to check 3 phase motor winding with multimeter is one of the most valuable skills for electricians, maintenance staff, technicians, and plant supervisors. It saves time, reduces repair costs, and prevents unexpected equipment shutdowns. The entire process is simple, accurate, and requires only a basic multimeter.

Know more about DIY Fix Overheated Electric Motor: 5 Proven Tips for a Smoother, Reliable Performance

By using the steps described above, you can safely test continuity, resistance, phase balance, and insulation. You can also detect early signs of problems that would otherwise be invisible.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#3PhaseMotor, #MotorWindingTest, #MultimeterTesting, #ElectricalMaintenance, #IndustrialMotors, #MotorRepairGuide, #ElectricalSafety, #TroubleshootingMotors, #EngineeringBasics, #ElectricMotorTesting