Earthing Cable Size Calculation: Important Guide

Proper earthing is a critical component of electrical systems, providing a safe path for fault currents to protect equipment and personnel. Determining the correct earthing cable size is essential to ensure the safety and efficiency of electrical installations. This guide will walk you through the fundamentals of earthing cable size calculation, including step-by-step instructions, factors affecting cable size, and methods to calculate it.

Table of Contents

What Is Earthing Cable Size Calculation?

The term “earthing cable size calculation” refers to the process of determining the ideal cross-sectional area for an earthing conductor in an electrical system. Choosing the correct size ensures that the earthing system can handle potential fault currents without damage, overheating, or compromising safety. A properly sized earthing cable provides an efficient path for fault currents, reduces voltage surges, and minimizes the risk of electric shocks.

Importance of Earthing Cable Size Calculation

Earthing cable size calculation plays a vital role in:

- Ensuring safety by preventing electric shocks.

- Protecting equipment from high fault currents.

- Reducing the likelihood of electrical fires.

- Complying with regulatory standards for safe electrical installations.

Accurate calculations are especially important in industrial and commercial installations where large currents may be involved.

Factors Affecting Earthing Cable Size

Several factors can influence the size of the earthing cable needed, including:

Fault Current: The maximum fault current the earthing system may encounter.

Soil Resistivity: High-resistivity soils require larger cables to ensure effective earthing.

Length of Cable: Longer cables often have more resistance, affecting the cross-sectional area.

Material: Copper and aluminum are common choices; copper typically requires a smaller cross-section for the same current due to its higher conductivity.

Type of Earthing System: Systems such as TN-S, TT, and TN-C-S have different requirements, impacting the cable size.

Temperature Rise: Higher temperatures reduce the cable’s current-carrying capacity, necessitating larger cables to safely carry the load.

Methods for Earthing Cable Size Calculation

Method 1: Using IEC Standards

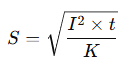

The International Electrotechnical Commission (IEC) provides standardized methods to calculate earthing cable sizes. According to IEC 60364-5-54, the cross-sectional area of an earthing conductor (S) can be determined with the formula:

where:

- I = Fault current in amperes (A)

- t = Duration of fault in seconds (s)

- k = Material constant, varying by conductor type and insulation (e.g., for copper, k is around 115 for short circuits).

This calculation method is widely used because it is simple, reliable, and suitable for most low-voltage installations. We can easily determine the earthing cable size as per IEC using this guide.

Method 2: Calculating Based on Adiabatic Equation

For more precise calculations, the adiabatic equation can be applied, especially in high-power systems. This method considers thermal energy generated by the fault current:

where:

- I = Fault current

- t = Fault duration

- K = Constant based on conductor material

The adiabatic equation is particularly useful for calculating earthing cable sizes for medium-voltage installations, providing a more accurate result by factoring in heat dissipation over time.

Note: Use our online electrical load calculator for electrical load calculation here. You can also use voltage drop calculator for voltage drop calculation for cable selection in any single and three phase circuit here. Further explore our online electrical calculators to design your electrical systems in an efficient way.

Step-by-Step Guide to Earthing Cable Size Calculation

Step 1: Determine Fault Current (I)

- Use the system’s design specifications to identify the maximum fault current. For example, in most installations, the expected fault current may range between 10,000 and 20,000 A.

Step 2: Calculate Fault Duration (t)

- Fault duration is the time it takes for protective devices, like circuit breakers, to disconnect the faulty circuit. For typical low-voltage circuits, this duration is usually between 0.1 and 1 second.

Step 3: Select Conductor Material

- Choose the earthing cable material based on system requirements. Copper is often preferred due to its high conductivity and durability, though aluminum is used for cost savings in larger installations.

Step 4: Apply the IEC or Adiabatic Formula

- Insert the values for I, t, and k (or K) into the chosen formula. If using the IEC method for a copper conductor, use k = 115. If using aluminum, k = 76 is standard.

Step 5: Cross-check with Standards

- Verify your calculated value with relevant local or international standards. Always ensure the calculated size meets or exceeds the minimum requirements outlined in regulations.

Practical Example of Earthing Cable Size Calculation

Suppose a facility has a maximum fault current of 15,000 A, and the protection system is designed to disconnect faults within 0.5 seconds. If using a copper conductor, the earthing cable size as per IEC calculation would look like this:

Using the IEC formula:

This means a copper earthing cable with a minimum cross-sectional area of 131 mm² would be required.

Additional Tips for Selecting Earthing Cables

Consider Temperature Variations: In areas with high ambient temperatures, consider a larger cable size to maintain current-carrying capacity.

Account for Soil Conditions: In high-resistivity soils (e.g., sandy or rocky soils), increase the cross-section or use a lower-resistance material.

Protect Against Corrosion: Use corrosion-resistant materials, particularly in outdoor installations or where the soil may be acidic.

Common Mistakes in Earthing Cable Size Calculation

- Ignoring Fault Duration: Always use the accurate fault-clearing time to avoid undersizing the cable.

- Not Considering Temperature Ratings: Higher operating temperatures reduce cable capacity, which may lead to overheating.

- Overlooking Material Properties: Different materials have different capacities; avoid generalizing copper and aluminum sizes.

- Skipping Standards Check: Failing to check calculations against local regulations may lead to non-compliance and safety issues.

Conclusion

Earthing cable size calculation is essential for designing a safe and efficient electrical grounding system. By following the step-by-step approach outlined above, you can ensure that your earthing conductor meets safety and operational requirements, protects against electric shocks, and complies with regulations. Always consult relevant standards and double-check your calculations to ensure accuracy, especially in industrial and commercial applications where safety is paramount.

In summary, calculating the proper earthing cable size involves understanding fault current, duration, material properties, and system standards. With this comprehensive approach, you can effectively design a reliable earthing system for your electrical installations.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

EarthingCableSize, #EarthingCalculation, #ElectricalEngineering, #CableSizing, #GroundingSystem, #EarthingGuide, #ElectricalSafety, #EarthCableSize, #ElectriciansGuide, #PowerSystemDesign, #CableSizeCalculation, #ElectricalInstallation, #GroundingCable, #SafeElectricalSystems, #EarthingStandards