Busbar Impedance Calculation — Complete Guide for Accurate Power System Analysis & Design

Busbars are the backbone of electrical distribution inside substations, switchboards, and industrial panels. They carry large currents, interconnect feeders, and influence short circuit behavior across the network. Because of this central role, engineers pay close attention to busbar impedance calculation during planning, protection coordination, and system expansion studies. A precise understanding of impedance helps avoid voltage instability, overheating, and incorrect fault level assumptions.

Table of Contents

This guide explains the engineering logic behind busbar impedance calculation in a practical and readable manner. It covers core theory, design factors, simplified formulas, and examples that reflect real-world power system work. The aim is to provide a clear technical reference that supports accurate modeling and dependable installation outcomes.

Understanding the Role of Busbar Impedance

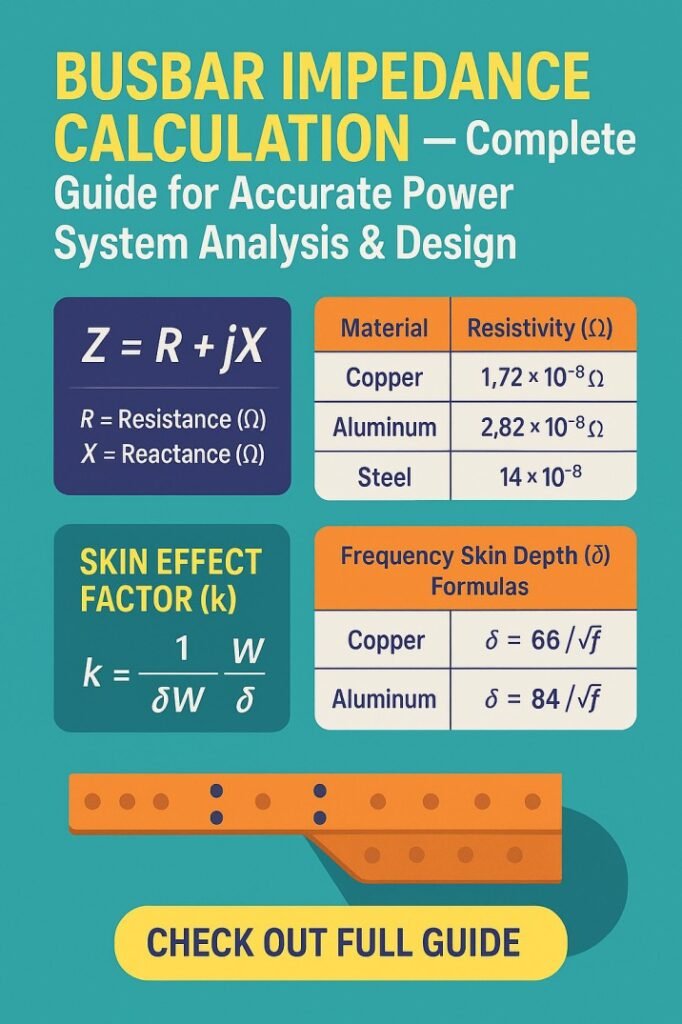

Impedance represents the opposition a conductor offers to alternating current. In busbars, impedance is influenced by resistance and reactance together. Resistance arises from conductor material and temperature, while reactance depends on geometry and electromagnetic effects. When performing busbar impedance calculation, engineers are essentially determining how the bus structure affects current flow and voltage profile.

Find all about Busbar Size Chart in mm

In power system analysis, impedance data feeds directly into load flow studies, protection settings, and short circuit evaluation. Even slight errors can distort relay coordination or equipment rating assumptions. This is why busbar impedance calculation is considered a foundational step in switchgear and substation engineering.

Electrical Parameters That Influence Impedance

Several physical and electrical parameters shape the final impedance value. Understanding these ensures realistic modeling.

Table 1: Key factors affecting busbar impedance

| Parameter | Engineering Impact | Typical Consideration |

|---|---|---|

| Material type | Copper and aluminum differ in resistivity | Copper preferred for lower losses |

| Cross sectional area | Larger area reduces resistance | Selected based on ampacity |

| Spacing between phases | Affects inductive coupling | Determined by insulation level |

| Busbar length | Directly proportional to impedance | Included in layout planning |

| Operating frequency | Impacts reactance magnitude | Usually 50 or 60 Hz |

| Skin effect | Raises AC resistance at high current | Important in thick bars |

Accounting for these inputs ensures busbar impedance calculation reflects actual installation conditions instead of theoretical assumptions.

Find all about Busbar Bending Calculation

Resistance Component Evaluation

Resistance is usually the simplest part to determine. It depends on conductor resistivity, length, and cross section. The basic relation used in busbar impedance calculation is:

R = ρ × L / A

Where R is resistance, ρ is material resistivity, L is length, and A is cross sectional area. Temperature correction is applied because conductor heating increases resistance. Engineers often multiply base resistance by a temperature factor derived from manufacturer data or standards.

For example, copper busbars operating at elevated temperature inside enclosed switchgear may show noticeable deviation from nominal resistance. Accurate modeling requires incorporating this variation during busbar impedance calculation.

Reactance Component and Magnetic Effects

Reactance originates from alternating magnetic fields surrounding current carrying conductors. It depends heavily on physical arrangement and spacing. Unlike resistance, reactance cannot be estimated solely from material data.

Find out more about Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

For simplified layouts, inductive reactance may be approximated using geometry based formulas or tabulated coefficients. Electromagnetic modeling software provides more precise results for complex arrangements. During busbar impedance calculation, reactance often dominates overall impedance in high current installations.

This component becomes particularly important when evaluating transient stability, harmonics, or fault current contribution. Ignoring geometry effects leads to unrealistic power system predictions.

Combined Impedance Determination

Total impedance is expressed as a complex value combining resistance and reactance. The magnitude can be determined using:

Z = √(R² + X²)

This representation enables engineers to incorporate both energy loss and magnetic influence into system simulations. Completing busbar impedance calculation at this stage allows integration into network impedance diagrams or simulation tools.

Find out more about High Impedance Busbar Protection Explained with Example Calculations

Table 2: Example simplified impedance estimation

| Parameter | Value |

|---|---|

| Busbar length | 5 m |

| Resistance | 0.00015 ohm |

| Reactance | 0.00030 ohm |

| Calculated impedance | 0.00034 ohm |

Such tabulated summaries help validate results before inclusion in larger studies.

Example of Busbar Impedance Calculation

To understand how busbar impedance calculation is applied in real engineering work, consider a simplified case from a low voltage distribution panel. The objective is to estimate impedance for use in a short circuit and voltage drop review. This example demonstrates the process without excessive mathematical complexity while still reflecting professional practice.

Find out more about Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

Assume a three phase copper busbar installed in an indoor switchboard. The layout data and electrical properties are known from drawings and manufacturer documentation. These inputs form the foundation for busbar impedance calculation before integrating results into system studies.

Table 4: Design inputs for example evaluation

| Parameter | Value | Notes |

|---|---|---|

| Material | Copper | High conductivity conductor |

| Length | 4 m | Measured path length |

| Cross sectional area | 400 mm² | Rectangular bar equivalent |

| Resistivity at operating temperature | 0.021 ohm mm²/m | Adjusted for heating |

| Estimated reactance | 0.00025 ohm | Based on spacing geometry |

| Frequency | 50 Hz | Standard network frequency |

Step 1 — Resistance Determination

The first stage in busbar impedance calculation is determining conductor resistance. Using the standard relation:

R = ρ × L / A

Find out more about iec 61439 busbar clearance

Substituting the values:

R = 0.021 × 4 / 400

R = 0.00021 ohm

This value represents the real component of opposition to current flow after accounting for operating temperature.

Step 2 — Reactance Consideration

Reactance is derived from phase spacing and electromagnetic coupling. Detailed modeling tools often generate precise values, but approximate geometry data can be used for planning studies. In this scenario, the estimated inductive reactance for the bus arrangement is:

X = 0.00025 ohm

Including reactance in busbar impedance calculation ensures magnetic field interaction is reflected in the final result.

Step 3 — Total Impedance Evaluation

The magnitude of impedance is determined by combining resistance and reactance:

Z = √(R² + X²)

Z = √((0.00021)² + (0.00025)²)

Z = √(0.0000000441 + 0.0000000625)

Z ≈ √(0.0000001066)

Z ≈ 0.00033 ohm

Get complete information about iec standard for busbar sizing

This result represents the effective opposition presented by the bus structure to alternating current.

Table 5: Summary of calculated results

| Component | Calculated Value |

|---|---|

| Resistance | 0.00021 ohm |

| Reactance | 0.00025 ohm |

| Total impedance | 0.00033 ohm |

Interpretation for Engineering Decisions

This completed busbar impedance calculation can now be used in multiple system evaluations. Protection engineers may include it in fault current modeling, while design teams may verify voltage drop performance. If results indicate higher impedance than acceptable, engineers might increase cross section or adjust spacing to optimize performance.

The example highlights the structured reasoning behind busbar impedance calculation and shows how theoretical equations translate into practical design data. Even simplified evaluations provide valuable insight when performed carefully and documented correctly.

Read in detail about iec 61439 busbar calculation

Practical Steps in Engineering Workflow

A structured approach improves reliability and consistency when conducting busbar impedance calculation.

Table 3: Typical workflow steps

| Step | Description |

|---|---|

| Data collection | Obtain layout dimensions and material properties |

| Resistance computation | Apply resistivity and temperature factors |

| Reactance estimation | Use geometry or simulation data |

| Impedance synthesis | Combine components mathematically |

| Validation | Compare with design references or software output |

This systematic process ensures results align with practical operating conditions.

Importance in Fault Level and Protection Studies

One of the major reasons engineers emphasize busbar impedance calculation is its influence on fault current estimation. Busbars with low impedance allow high short circuit current, affecting breaker rating and relay settings. Overlooking impedance may result in underestimated fault levels and equipment stress.

Protection coordination also relies on accurate impedance data. Relay pickup values and time grading depend on realistic network modeling. Therefore busbar impedance calculation supports system reliability and safety beyond simple conductor sizing considerations.

Know more about IEC Standard for Busbar Clearance

Design Optimization and Efficiency Considerations

Engineers often use busbar impedance calculation during optimization phases. Adjusting spacing, material choice, or geometry can improve performance without large cost increases. Lower impedance reduces losses and enhances voltage stability.

In renewable energy integration or industrial load expansion, recalculating parameters ensures existing bus structures remain suitable. Busbar impedance calculation thus becomes an ongoing design tool rather than a one time exercise.

Simulation Tools and Field Validation

Modern design frequently combines analytical methods with software modeling. Digital simulation provides detailed electromagnetic insight, especially in complex switchgear assemblies. Despite advanced tools, manual busbar impedance calculation remains valuable for cross checking and conceptual understanding.

Field validation through measurement or commissioning tests further confirms assumptions. Combining theory and observation strengthens engineering confidence and ensures dependable operation.

Find out more about contact resistance test acceptable value for busbar

Common Challenges and Engineering Tips

Performing busbar impedance calculation can present several challenges. Engineers sometimes overlook enclosure proximity effects or assume uniform temperature distribution. These simplifications introduce error. Maintaining updated material data and verifying geometry dimensions helps maintain accuracy.

Clear documentation of assumptions is also important. Future upgrades often rely on existing calculation records. Consistent methodology ensures subsequent busbar impedance calculation remains comparable and traceable.

Conclusion

Reliable electrical distribution depends on understanding how current flows through structural conductors. Busbars play a central role, and their electrical characteristics directly affect system stability, losses, and fault response. Performing busbar impedance calculation with careful attention to material properties, geometry, and operating conditions ensures realistic system modeling and safer equipment selection.

Dive deeper into contact resistance measurement test

From resistance evaluation to reactance estimation and final integration into protection studies, busbar impedance calculation supports both design accuracy and operational confidence. Engineers who approach this task methodically gain clearer insight into network behavior and make better informed decisions. By combining analytical understanding with practical validation, power system professionals can ensure efficient, resilient, and future ready infrastructure.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#BusbarImpedanceCalculation, #ElectricalEngineering, #PowerSystemDesign, #SwitchgearDesign, #FaultCurrentAnalysis, #BusbarSizing, #ElectricalCalculations, #PowerDistribution, #EngineeringTools, #ElectricalStandards