Automatic Stator Winding Machine: Best Guide

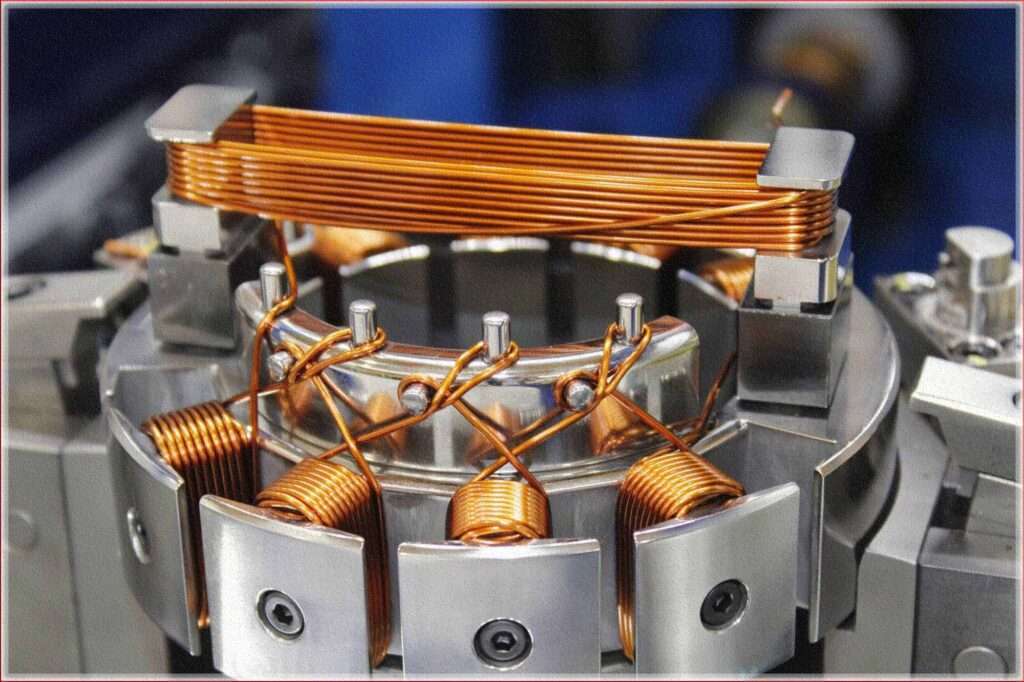

An automatic stator winding machine is a specialized piece of equipment used in the manufacturing process of electric motors and generators. It is designed to automate the winding process of stator coils, which are a crucial component in these machines.

Read More

By utilizing advanced technology and precise control systems, an automatic stator winding machine enhances efficiency, accuracy, and productivity in the production of electrical machinery. Let’s delve into the details of this innovative machine.

The automatic stator winding machine streamlines the entire stator winding process, eliminating the need for manual labor and significantly reducing human error.

Features of Automatic Stator Winding Machine

This machine consists of several key components and features:

Control System: The machine is equipped with a sophisticated control system that allows operators to set various parameters such as winding speed, wire tension, winding direction, and number of turns. This level of control ensures consistent and precise winding results.

Wire Feeding Mechanism: The machine features an automatic wire feeding mechanism that accurately measures and feeds the wire onto the stator core. This mechanism ensures the correct wire tension and prevents wire tangling or overlapping during the winding process.

Coil Formers: The automatic stator winding machine includes interchangeable coil formers that accommodate different stator sizes and winding configurations. These coil formers hold the stator core securely in place and guide the wire as it is wound around the core.

Winding Head: The winding head is a crucial part of the machine that carries out the actual winding process. It rotates around the stator core while precisely laying the wire in the desired pattern and number of turns. The winding head’s movement is synchronized with the control system to achieve the desired winding configuration.

Tension Control System: To ensure proper wire tension throughout the winding process, the machine employs a tension control system. This system maintains consistent tension on the wire, preventing slack or excessive tension that could affect the quality of the stator coils.

Cut and Form Mechanism: After completing the winding process, the machine incorporates a cut and form mechanism. This mechanism trims the wire to the appropriate length and bends the wire ends to secure them in place, forming neat and reliable coil terminations.

Safety Features: Automatic stator winding machines are equipped with various safety features, such as emergency stop buttons, protective enclosures, and sensors to detect wire breakage or abnormal operating conditions. These features ensure operator safety and prevent damage to the machine and the stator itself.

Automatic stator winding machines offer numerous advantages over manual winding processes. They significantly improve productivity, reduce labor costs, enhance product quality and consistency, and minimize the potential for human error. Moreover, these machines can handle a wide range of stator sizes and winding configurations, making them adaptable to different motor and generator designs.

Unknown Facts on Automatic Stator Winding Machine

In addition to the main components and features mentioned earlier, here are some lesser-known details about automatic stator winding machines:

Programming Flexibility: Modern automatic stator winding machines often come equipped with advanced programming capabilities. Operators can program complex winding patterns and configurations, allowing for customized stator designs to meet specific motor or generator requirements.

Data Logging and Analysis: Some machines offer data logging and analysis capabilities, allowing operators to track and analyze production data. This data can include winding speed, wire tension, error rates, and other relevant parameters, enabling manufacturers to optimize processes and identify potential improvements.

Automatic Wire Splicing: Certain automatic stator winding machines are equipped with automatic wire splicing capabilities. This feature enables the machine to splice the wire ends together seamlessly during the winding process, eliminating the need for manual splicing and ensuring a continuous and reliable winding operation.

Multi-Zone Wire Temperature Control: To prevent wire overheating during the winding process, advanced machines incorporate multi-zone wire temperature control. This feature monitors and adjusts the temperature of the wire at various stages to maintain optimal winding conditions and prevent insulation damage.

Integration with Production Lines: Automatic stator winding machines can be integrated into larger production lines, allowing for seamless automation and synchronization with other manufacturing processes. This integration enhances overall production efficiency and reduces cycle times.

Remote Monitoring and Maintenance: Some machines offer remote monitoring and maintenance capabilities, enabling operators to monitor machine performance, diagnose issues, and perform maintenance tasks remotely. This feature improves machine uptime and reduces the need for on-site troubleshooting.

By utilizing an automatic stator winding machine, manufacturers can achieve high-quality stator coils with improved efficiency, consistency, and accuracy. These machines offer advanced features and capabilities that optimize the winding process, resulting in reliable and high-performance electric motors and generators.

Related Posts:

- Excitation Systems: Components & 4 Important Methods

- Squirrel Cage Induction Motor: Working and Best Applications

- Wound Rotor Induction Motor: Working & Important Applications

- Induction Motor: Important Types, Construction & Working

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.