NEC NFPA 70 2026 — Complete Guide to Code Updates, Compliance Requirements, and Electrical Safety Standards

Electrical installations evolve as technology, safety practices, and equipment standards change. For engineers, contractors, inspectors, and facility owners, understanding NEC NFPA 70 is not optional. It is the foundation of safe electrical design, installation, and maintenance. The 2026 cycle continues this tradition by refining rules that protect people, property, and infrastructure from electrical hazards.

Table of Contents

This guide explains the structure, compliance expectations, and safety principles surrounding NEC NFPA 70 in a practical and readable manner, while highlighting how professionals can apply it effectively in real projects.

Understanding NEC NFPA 70 and Its Role in Electrical Systems

NEC NFPA 70 represents the National Electrical Code published by the National Fire Protection Association. It sets minimum standards for safe electrical installations in residential, commercial, and industrial environments. While it is not federal law, jurisdictions adopt NEC NFPA 70 into enforceable regulations, making it a core reference for electrical compliance.

The code addresses installation practices for wiring systems, grounding methods, overcurrent protection, equipment selection, and workplace safety. It integrates terminology and requirements aligned with broader electrical safety standards, including coordination with workplace safety guidance and inspection procedures. Engineers rely on NEC NFPA 70 to design systems that reduce fire risks, prevent shock incidents, and maintain operational reliability.

Explore details on iec and ieee standards

Professionals often describe NFPA 70 as both a design guide and a safety framework. It ensures uniform practices across projects while allowing flexibility for evolving technologies such as renewable energy integration, energy storage systems, and electric vehicle infrastructure.

Structural Organization of NEC NFPA 70

To use NEC NFPA 70 effectively, one must understand its structure. The code follows a logical chapter arrangement that separates general rules from specialized installations. This organization allows readers to locate relevant provisions quickly during design reviews or site inspections.

Table 1 shows the simplified layout that most users encounter when navigating NFPA 70.

Table 1 — General Structure Overview

| Chapter | Scope Description | Practical Application |

|---|---|---|

| 1 | General definitions and rules | Terminology, applicability, enforcement |

| 2 | Wiring and protection | Branch circuits, feeders, overcurrent devices |

| 3 | Wiring methods and materials | Conductors, raceways, cable types |

| 4 | Equipment for general use | Switchboards, panelboards, motors |

| 5 | Special occupancies | Hazardous locations, healthcare |

| 6 | Special equipment | Solar, generators, storage systems |

| 7 | Special conditions | Emergency systems, standby power |

| 8 | Communication systems | Data, telecom infrastructure |

| 9 | Tables and annexes | Conductor properties, references |

Understanding this framework allows engineers to move between general and application-specific sections without confusion. This familiarity reduces design errors and improves review efficiency.

Know more about Phase to Phase Clearance as per IEC 61439: Best Guide

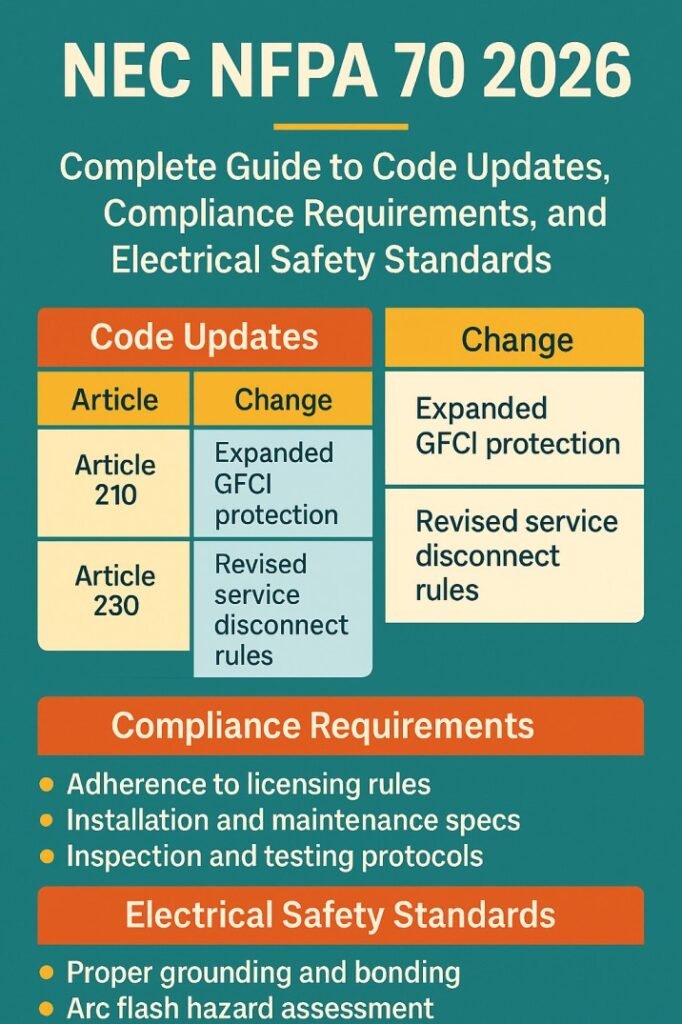

Key Themes Reflected in 2026 Cycle Updates

Every revision cycle refines NEC NFPA 70 to address industry changes and incident data. Although final adoption details vary by jurisdiction, the 2026 edition emphasizes modernization, resilience, and integration of distributed energy technologies.

One notable theme is the continued expansion of guidance related to renewable energy sources. Solar photovoltaic installations, hybrid inverter systems, and grid-interactive equipment are addressed with improved clarity. Requirements focus on disconnecting means, conductor protection, and labeling practices to support safer maintenance and emergency response.

Energy storage integration also receives attention. With battery systems becoming more common in commercial and residential facilities, NEC NFPA 70 introduces clearer installation boundaries, ventilation considerations, and coordination with fire safety protocols.

Electric vehicle charging infrastructure remains another focal area. As adoption increases, NEC NFPA 70 strengthens provisions around circuit sizing, grounding continuity, and load management coordination to prevent overheating and ensure stable operation.

Engineers reviewing updates should focus on these broader themes rather than isolated rule changes. This approach ensures compliance planning aligns with long-term industry direction.

Compliance Requirements for Designers and Installers

Applying NEC NFPA 70 effectively requires more than reading articles. It involves integrating compliance into each project phase, from conceptual design to commissioning. Engineers must ensure conductor sizing, protective device coordination, and equipment ratings align with code provisions.

The compliance process generally follows several practical steps summarized in Table 2.

Know more about How to Comply with OSHA Electrical Standards in detail

Table 2 — Compliance Workflow Reference

| Phase | Action | Objective |

|---|---|---|

| Planning | Identify applicable code sections | Define project scope |

| Design | Apply load calculations | Ensure system capacity |

| Specification | Select listed equipment | Meet safety certification |

| Installation | Follow wiring methods | Maintain integrity |

| Inspection | Verify conformity | Obtain approval |

| Documentation | Maintain records | Support lifecycle compliance |

This structured workflow helps project teams integrate NEC NFPA 70 requirements seamlessly into execution. Consistent documentation and verification prevent costly redesigns or failed inspections.

Electrical Safety Principles Embedded in NEC NFPA 70

At its core, NEC NFPA 70 is about reducing electrical hazards. It addresses common risks such as shock exposure, conductor overheating, arc faults, and fire ignition sources. Safety provisions emphasize proper grounding, bonding continuity, and reliable overcurrent protection.

Know more about Electrical Standards USA – National Electrical Code | Electrical Safety Foundation

Grounding ensures fault currents return safely to their source, allowing protective devices to operate. Bonding minimizes potential differences between conductive parts, protecting personnel and equipment. Circuit protection limits damage caused by overloads or short circuits.

Table 3 highlights typical hazard categories addressed within NEC NFPA 70 and their associated preventive strategies.

Table 3 — Hazard Mitigation Reference

| Hazard Type | Code Strategy | Resulting Protection |

|---|---|---|

| Electric shock | Grounding and bonding rules | Personnel safety |

| Overcurrent | Breakers and fuses | Equipment protection |

| Arc faults | Detection requirements | Fire reduction |

| Insulation failure | Wiring method controls | System reliability |

| Equipment misuse | Listing and labeling | Standardized safety |

Professionals working in design or maintenance roles should view these principles as interconnected layers rather than isolated rules.

Learn more in detail on NEMA 250 Enclosures – Electrical Enclosure Standards | Best Manufacturing Companies in USA

Applying NEC NFPA 70 in Modern Infrastructure Projects

Modern facilities integrate automation, digital monitoring, and renewable generation. NEC NFPA 70 supports these environments by offering adaptable guidance covering diverse installations. Industrial plants rely on its provisions when configuring motor control centers or hazardous location equipment. Commercial buildings reference it when installing emergency power systems and lighting controls. Residential developers depend on it for service entrance layout and branch circuit distribution.

For example, when implementing photovoltaic systems, engineers consider conductor routing, disconnect accessibility, and overcurrent coordination in line with NEC NFPA 70. In data center construction, adherence ensures balanced load distribution and reliable grounding, protecting sensitive equipment from disturbances.

Know more about What is Standard Voltage in USA? All You need to Know

Successful application often involves collaboration among multiple disciplines. Electrical engineers coordinate with civil planners, safety officers, and inspectors to ensure installations meet performance expectations while satisfying NEC NFPA 70 criteria.

Inspection and Enforcement Considerations

Inspection authorities play a central role in verifying adherence to NEC NFPA 70. Their evaluation covers physical installation practices, documentation, and equipment labeling. Engineers who anticipate inspection requirements early tend to experience smoother approvals.

Key preparation strategies include maintaining updated drawings, documenting calculation assumptions, and verifying component certifications. Clear labeling of disconnects, feeders, and panelboards demonstrates professionalism and aligns with NEC NFPA 70 identification practices.

Inspection outcomes influence operational timelines and liability exposure. Noncompliance can result in delays or penalties, making proactive preparation essential for project success.

Best Practices for Staying Current With NEC NFPA 70

The electrical industry evolves continuously. Engineers should treat NEC NFPA 70 as a living reference rather than a static manual. Continuous learning through seminars, professional workshops, and peer discussions keeps knowledge aligned with revisions.

Use our online tool electricity load calculator in kw for home

Maintaining updated personal references and participating in technical communities strengthens awareness of interpretation trends. Practical exposure through project work reinforces understanding of how NEC NFPA 70 applies beyond theoretical scenarios.

Companies that invest in training programs often see improved safety performance and reduced compliance risk. This commitment also enhances professional credibility in competitive markets.

Conclusion

NEC NFPA 70 remains the cornerstone of safe electrical installation practice. The 2026 cycle reflects ongoing adaptation to technological advancement, renewable integration, and infrastructure modernization. By understanding its structure, applying compliance workflows, and respecting its embedded safety principles, professionals can design and install systems that perform reliably and protect occupants.

Dive deeper into instrument earthing iec standard

Engineers who engage deeply with NEC NFPA 70 not only meet regulatory expectations but also elevate project quality. Whether working on residential wiring, industrial automation, or renewable generation, consistent application of NEC NFPA 70 ensures alignment with recognized safety benchmarks and operational resilience. Continuous learning and careful implementation transform the code from a regulatory requirement into a strategic engineering asset.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#NECNFPA702026, #NEC2026, #NFPA70, #ElectricalCode, #ElectricalEngineering, #CodeCompliance, #ElectricalSafety, #WiringStandards, #PowerSystems, #Electricians