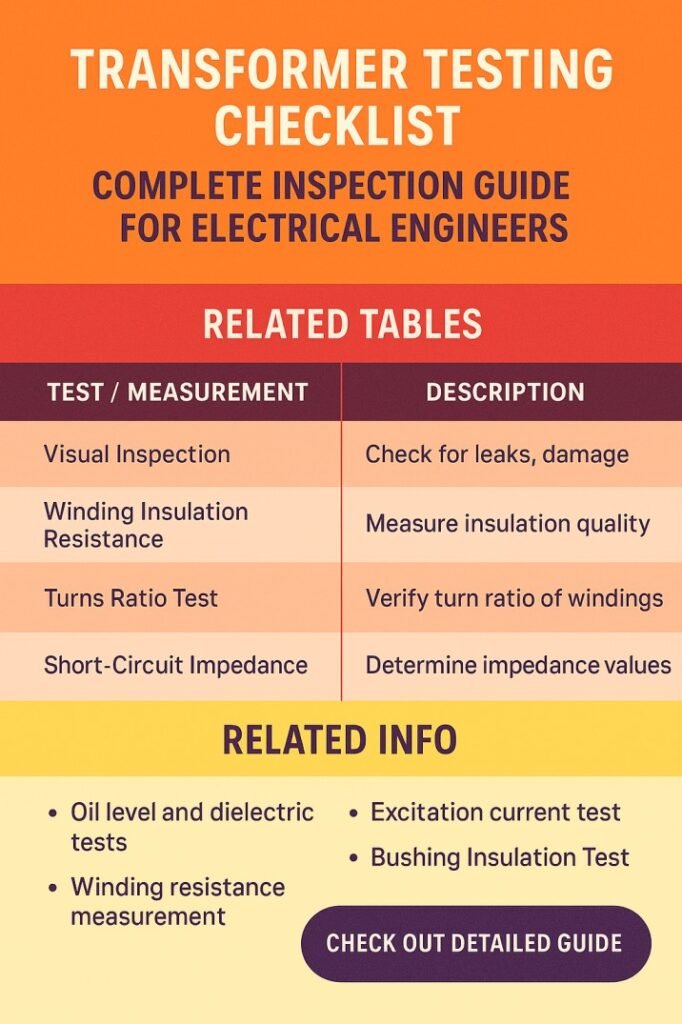

Transformer Testing Checklist | Important Inspection Guide for Electrical Engineers

A reliable power system depends heavily on the health of its transformers. Whether installed in industrial plants, substations, or renewable energy projects, these assets must be inspected methodically before commissioning and throughout their service life. A well-structured transformer testing checklist helps engineers verify performance, detect hidden defects, and prevent unplanned outages.

Table of Contents

This guide presents a practical inspection approach based on field experience and standard engineering practice, making it suitable for site engineers, maintenance professionals, and commissioning teams.

Importance of a Structured Testing Approach

Transformers operate under electrical, thermal, and mechanical stress. Small issues such as insulation degradation, loose connections, or winding imbalance can escalate into major failures. Using a transformer testing checklist ensures no essential verification step is missed during routine inspection or acceptance testing. It also creates documented records that support condition monitoring and asset management.

Beyond compliance, systematic checks help optimize efficiency, reduce downtime, and improve safety. Parameters like winding resistance, insulation resistance, and oil quality provide valuable insight into transformer condition. Consistent documentation through a transformer testing checklist simplifies trending and comparison during future maintenance cycles.

Pre Inspection Preparation

Before physical or electrical tests begin, preparation is necessary. This stage ensures safety, correct equipment availability, and proper interpretation of results.

Use our onkline tool Transformer Short Circuit Calculator – Accurate Fault Current & Transformer Protection Tool

Safety and Documentation Review

A preliminary transformer testing checklist typically begins with reviewing drawings, manufacturer data, and safety procedures. Lockout and isolation must be verified. Environmental conditions should also be considered.

| Item | Verification Requirement | Purpose |

|---|---|---|

| Isolation confirmation | Ensure supply disconnected and grounded | Personnel safety |

| Nameplate data review | Record voltage, rating, vector group | Test reference |

| Tools and instruments | Calibration validity checked | Measurement accuracy |

| Work permits | Approved and displayed | Compliance |

| PPE availability | Gloves, helmet, arc protection | Hazard reduction |

Careful preparation improves test quality and aligns the process with accepted commissioning practices.

Know more about Transformer Oil Testing: 9 Important Tests for Healthiness

Visual and Mechanical Inspection

Physical inspection is often the first practical step in a field transformer testing checklist. Many issues can be detected without applying electrical test equipment.

External Condition Checks

Engineers should observe structural condition, accessories, and installation alignment. Pay attention to bushings, radiators, conservators, and cable termination.

| Component | Inspection Points | Acceptance Criteria |

|---|---|---|

| Bushings | Cracks, contamination, oil leaks | Clean and intact |

| Tank and welds | Corrosion or deformation | No visible damage |

| Earthing connections | Tightness and continuity | Secure bonding |

| Cooling fans and pumps | Rotation and noise | Normal operation |

| Breather and silica gel | Moisture condition | Dry indicator color |

These observations strengthen the overall transformer testing checklist by identifying defects that may affect later electrical measurements.

Know more about Best Transformer Testing Companies in Canada | Trusted Electrical Testing Experts & Utility Service Providers

Electrical Testing Procedures

Electrical testing validates insulation integrity, winding health, and correct configuration. This part of the transformer testing checklist is often performed during commissioning or major maintenance.

Insulation Resistance Measurement

Insulation resistance testing confirms dielectric condition between windings and ground. It is commonly conducted using a megohmmeter. Results should be temperature corrected and compared with historical values.

Winding Resistance Test

Resistance measurements reveal loose joints or winding damage. Balanced readings across phases indicate good internal connections. Recording values within the transformer testing checklist helps identify gradual changes over time.

Ratio and Polarity Verification

Turns ratio testing ensures voltage transformation accuracy. Incorrect ratios may indicate tap changer issues or internal faults. Polarity checks confirm proper phasing before energization.

| Test | Instrument Used | Key Objective |

|---|---|---|

| Insulation resistance | Megger | Assess dielectric strength |

| Winding resistance | Micro ohmmeter | Detect loose joints |

| Turns ratio | TTR kit | Confirm ratio accuracy |

| Polarity check | Test source meter | Validate phasing |

| Vector group verification | Phase analyzer | Confirm configuration |

Including these procedures in a transformer testing checklist ensures electrical performance matches design expectations.

Read in detail about types of transformer protection relays

Oil Quality and Dielectric Tests

For oil filled units, fluid condition strongly influences insulation performance. Oil testing therefore forms an essential part of any comprehensive transformer testing checklist.

Sampling and Laboratory Analysis

Oil samples should be collected carefully to avoid contamination. Laboratory tests typically include dielectric breakdown voltage, moisture content, acidity, and dissolved gas analysis. These indicators reveal aging or internal arcing.

| Oil Parameter | Significance | Typical Concern |

|---|---|---|

| Breakdown voltage | Insulation strength | Moisture or contamination |

| Water content | Aging indicator | Reduced dielectric capacity |

| Acidity level | Oxidation status | Sludge formation |

| Dissolved gas | Fault detection | Thermal or electrical faults |

Regular monitoring incorporated into the transformer testing checklist helps extend service life and supports predictive maintenance strategies.

Find out more about transformer differential protection

Functional and Protection Checks

Transformers include auxiliary systems that require verification. Functional checks ensure protective devices operate as intended.

Operational Verification

Testing alarms, temperature indicators, and protection relays is necessary before energization. Engineers should confirm tap changer movement, gauge accuracy, and communication signals.

| Device | Test Action | Expected Result |

|---|---|---|

| Temperature indicator | Simulate heating | Alarm activation |

| Buchholz relay | Gas injection test | Trip signal |

| OLTC mechanism | Tap movement check | Smooth operation |

| Pressure relief device | Mechanical inspection | Free movement |

| Control wiring | Continuity test | Reliable signals |

These steps complete the functional portion of the transformer testing checklist and improve system reliability.

Know more about Top 20 Electrical Testing Tools Which You Must Have

Documentation and Result Evaluation

Testing does not end with measurement. Proper documentation is essential for engineering analysis and regulatory compliance. Each completed transformer testing checklist should include recorded readings, environmental conditions, and instrument details.

Trend comparison plays an important role here. Engineers evaluate whether deviations indicate deterioration or normal variation. Maintaining structured records allows predictive maintenance decisions and supports future troubleshooting.

Practical Tips for Field Engineers

Experience shows that attention to detail significantly improves testing outcomes. Maintaining consistency in procedure execution ensures reliable data collection. Engineers should follow calibration schedules, use stable connections, and minimize environmental interference.

Know more about Best Megger Testers for Industrial Use

Integrating lessons learned into the transformer testing checklist improves its effectiveness over time. Updating checklists based on site experience also aligns inspection routines with evolving system demands and load profiles.

Conclusion

Transformers remain critical components in modern power networks, and their reliability depends on disciplined inspection routines. Applying a well designed transformer testing checklist allows engineers to evaluate mechanical integrity, electrical performance, oil condition, and protection functionality in a structured manner. From visual inspection to advanced diagnostics, each stage contributes valuable information about equipment health.

Consistent application of a transformer testing checklist not only enhances safety but also strengthens maintenance planning and operational stability. Engineers who document findings carefully and compare results over time gain deeper insight into asset behavior. Ultimately, systematic testing supports dependable energy delivery and prolongs transformer service life, making structured inspection practices an essential part of professional electrical engineering work.

Know more about Top 12 Electrical Testing Equipment Suppliers in USA

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerTesting, #TransformerChecklist, #ElectricalMaintenance, #PowerSystemTesting, #SubstationEngineering, #ElectricalInspection, #PreventiveMaintenance, #HighVoltageTesting, #ElectricalEngineers, #PowerEngineering