Transformer Sizing for Motor Starting | Important Calculation Guide for Electrical Engineers

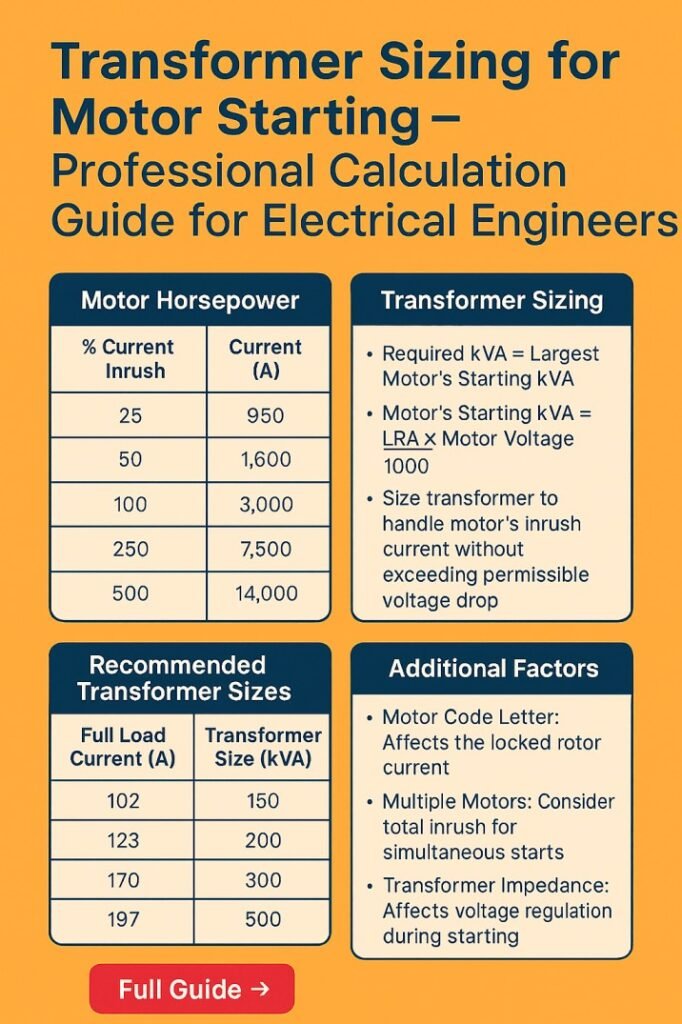

Transformer sizing for motor starting is a critical task in industrial power system design. Motors draw a high inrush current during acceleration, and an undersized transformer can cause severe voltage dip, nuisance tripping, or poor torque performance. Electrical engineers responsible for plant reliability must evaluate transformer sizing for motor starting carefully so that starting conditions remain stable without overspending on oversized equipment. This guide explains practical methods, calculations, and engineering judgement required to approach transformer sizing for motor starting in real installations.

Table of Contents

Understanding the Importance of Transformer Capacity During Motor Starting

When a motor starts across the line, it can draw six to eight times its rated current for a short duration. This transient demand is often referred to as locked rotor current or inrush current. Transformer sizing for motor starting must consider this surge because transformers experience voltage drop proportional to impedance and loading.

The challenge lies in balancing acceptable voltage dip with transformer utilization. Excessive voltage drop reduces motor torque, increases heating, and may disturb other connected loads. Proper transformer sizing for motor starting ensures that voltage regulation stays within tolerable limits while maintaining cost efficiency.

Typical factors influencing transformer sizing include system short circuit strength, transformer impedance percentage, motor starting method, and allowable voltage dip on the bus. Engineers also examine supply reliability and duty cycle because repeated starts impose thermal stress.

Know more about Transformer Oil Testing: 9 Important Tests for Healthiness

Key Parameters Required Before Calculation

Accurate transformer sizing for motor starting begins with collecting technical data. Missing or estimated parameters often lead to conservative oversizing or operational risk. Engineers should confirm the following inputs before proceeding.

| Parameter | Description | Typical Source |

|---|---|---|

| Motor Rated Power | Nameplate kW or HP value | Motor datasheet |

| Rated Voltage | Operating voltage level | System design document |

| Full Load Current | Steady state current | Manufacturer data |

| Locked Rotor Current | Starting current multiplier | NEMA code or datasheet |

| Transformer Impedance | Percent impedance value | Transformer test report |

| Allowed Voltage Dip | Maximum acceptable drop | Utility or plant standard |

| Starting Method | DOL, soft starter, VFD | Project specification |

Gathering these values allows structured transformer sizing for motor starting instead of relying on rule of thumb assumptions.

Read in detail about transformer manufacturers in egypt

Fundamentals of Motor Starting Current and Voltage Drop

Motor torque during acceleration depends on terminal voltage. If transformer sizing for motor starting neglects voltage drop, the motor may fail to accelerate. Voltage dip can be estimated through simplified relationships between current magnitude and transformer impedance.

The approximate voltage drop percentage is calculated as:

Voltage Drop % ≈ (Starting Current / Transformer Full Load Current) × Transformer Impedance %

This relationship highlights that transformer sizing for motor starting revolves around keeping the ratio within acceptable limits. Engineers typically allow 10% to 15% voltage dip for industrial processes, though sensitive systems demand stricter control.

Step by Step Calculation Approach

A systematic calculation improves consistency and design confidence. The following steps demonstrate a structured approach to transformer sizing for motor starting.

Step 1 Determine Motor Starting kVA

Motor starting apparent power is calculated using line voltage and locked rotor current.

Starting kVA = √3 × Voltage × Locked Rotor Current / 1000

This value represents instantaneous demand seen by the transformer.

Know more about Best Transformer Testing Companies in Canada | Trusted Electrical Testing Experts & Utility Service Providers

Step 2 Estimate Minimum Transformer Rating

A simplified estimate for transformer sizing for motor starting compares starting kVA with transformer rated kVA adjusted for acceptable voltage drop.

| Voltage Dip Limit | Recommended Transformer Multiplier |

|---|---|

| 5% | 4 to 5 times motor kVA |

| 10% | 3 to 4 times motor kVA |

| 15% | 2 to 3 times motor kVA |

These multipliers provide preliminary sizing guidance before refined analysis.

Step 3 Check Voltage Drop Using Impedance

Calculate transformer full load current from its rating and compare with motor starting current. Adjust transformer size until predicted voltage dip remains within target range. This iterative step ensures transformer sizing for motor starting reflects real operating conditions. Use our online tool for free Transformer Neutral Current Calculator – Accurate Neutral Current Estimation

Step 4 Verify Thermal Capability

Repeated starts generate heat in transformer windings. Engineers confirm that duty cycle and start frequency remain within thermal limits specified in manufacturer curves. Transformer sizing for motor starting must consider long term reliability, not just instantaneous voltage performance.

Example Calculation for Practical Understanding

Consider a 75 kW motor operating at 415 V with a locked rotor current of six times rated current. Rated current approximates 130 A, so starting current equals 780 A.

Starting kVA calculation gives:

Starting kVA ≈ √3 × 415 × 780 / 1000

Starting kVA ≈ 561 kVA

If acceptable voltage dip is 10%, selecting a transformer between three and four times motor rated kVA is reasonable. Engineers might evaluate a 500 kVA and 630 kVA option. Checking impedance and current ratios shows that transformer sizing for motor starting favors the 630 kVA unit because predicted voltage drop remains within limits.

Try our free online tool Transformer Temperature Rise Calculator: Accurate and Easy Guide

Influence of Motor Starting Methods

Different starting techniques significantly affect transformer sizing for motor starting. Reduced current methods lower stress on supply equipment and enable smaller transformer ratings.

| Starting Method | Typical Current Multiple | Impact on Transformer |

|---|---|---|

| Direct Online | 6 to 8 times FLC | Largest capacity needed |

| Star Delta | 2 to 3 times FLC | Moderate capacity |

| Soft Starter | Adjustable ramp | Reduced voltage dip |

| Variable Frequency Drive | Near rated current | Minimal impact |

Engineers evaluating transformer sizing for motor starting should always consider control technology options before finalizing capacity selection.

Practical Design Considerations in Industrial Systems

Real installations rarely involve a single motor. Multiple loads share distribution transformers, making diversity factor evaluation essential. Transformer sizing for motor starting must include simultaneous running loads and possible concurrent starts.

Use our tool online at no cost Transformer Losses Calculation Tool – Accurate & Easy Energy Loss Analysis

Engineers also account for supply stiffness and upstream network impedance. Weak grids magnify voltage fluctuation and influence transformer sizing decisions. Coordination with protection schemes ensures starting currents do not trigger nuisance trips.

Another consideration is future expansion. Oversizing slightly during transformer sizing for motor starting can accommodate additional motors without infrastructure replacement. However, excessive oversizing reduces efficiency and increases capital cost, so engineering balance is necessary.

Common Mistakes to Avoid

Design errors often occur when transformer sizing for motor starting is treated as a purely theoretical exercise. Ignoring measured site conditions or manufacturer data leads to unexpected operational problems. Frequent mistakes include neglecting impedance variation, assuming ideal voltage stability, or ignoring cumulative starting events.

Access our online tool completely free Transformer Vector Group Calculation Tool | Easy & Accurate Vector Group Calculator

Another issue arises when engineers rely solely on steady state calculations. Transient simulation or software analysis may reveal additional constraints, especially in complex plants. Effective transformer sizing for motor starting requires blending analytical calculations with practical field insight.

Recommended Engineering Workflow

A structured workflow improves repeatability and documentation quality when performing transformer sizing for motor starting.

| Stage | Engineering Action |

|---|---|

| Data Collection | Confirm motor and transformer parameters |

| Preliminary Estimate | Apply multipliers for quick sizing |

| Detailed Calculation | Evaluate voltage dip and current ratio |

| Verification | Check thermal and operational constraints |

| Documentation | Record assumptions and results |

This disciplined approach helps engineers justify design decisions and maintain project traceability.

Test our online tool for free Transformer Full Load Current Calculator – Accurate Load & Current Calculation Tool for Transformers

Conclusion

Transformer sizing for motor starting remains a fundamental competency for electrical engineers working in industrial power systems. Correct evaluation protects equipment, ensures stable voltage, and supports efficient motor acceleration. By understanding inrush behavior, collecting accurate data, and applying structured calculations, engineers can approach transformer sizing for motor starting with confidence.

Practical judgement always complements mathematical analysis. Considering starting methods, load diversity, and system expansion leads to robust solutions rather than minimal compliance. When transformer sizing for motor starting is handled professionally, facilities benefit from improved reliability, reduced downtime, and optimized capital investment.

Start using our online tool today — it’s free Transformer Short Circuit Calculator – Accurate Fault Current & Transformer Protection Tool

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerSizing, #MotorStarting, #ElectricalEngineering, #PowerSystemDesign, #LoadCalculations, #SubstationDesign, #IndustrialMotors, #EngineeringGuides, #PowerDistribution, #EEHub