Transformer Sizing Calculation as per IEC — Professional Engineering Guide for Accurate Load & Capacity Selection

Transformer selection is not just about picking the next standard rating from a catalog. A reliable installation depends on correct load evaluation, thermal margins, voltage regulation limits, and compliance with recognized standards. Engineers working on industrial plants, renewable projects, or commercial power systems often rely on transformer sizing calculation as per IEC to ensure performance, safety, and lifecycle efficiency.

Applying the IEC framework provides a structured method for determining transformer capacity while considering ambient conditions, demand diversity, and future expansion.

Table of Contents

This guide explains transformer sizing calculation as per IEC in practical engineering terms. It walks through load estimation, diversity application, and derating considerations while presenting useful tables for field reference. The aim is to help you carry out transformer sizing calculation as per IEC accurately and consistently across different applications.

Know more about Transformer Oil Testing: 9 Important Tests for Healthiness

Importance of Standardized Transformer Sizing

Using transformer sizing calculation as per IEC aligns design practice with internationally accepted technical requirements. IEC 60076 and associated guidelines define performance parameters such as temperature rise, losses, insulation coordination, and test conditions. When transformer sizing calculation as per IEC is performed correctly, the selected unit operates within permissible loading limits, avoids overheating, and maintains voltage stability.

Engineers benefit from applying transformer sizing calculation as per IEC because it minimizes under-sizing risks that cause overload and insulation stress. It also prevents unnecessary oversizing that increases capital cost and no-load losses. Accurate sizing supports energy efficiency targets and ensures proper integration with switchgear ratings, protective relays, and cable sizing.

Key Data Required Before Calculation

Before performing transformer sizing calculation as per IEC, gather complete system information. Accurate inputs determine the credibility of the result. Typical design data includes connected loads, utilization factors, voltage levels, power factor, and installation environment.

Test our online tool for free Transformer Full Load Current Calculator – Accurate Load & Current Calculation Tool for Transformers

Table 1 summarizes the typical inputs needed.

| Parameter | Description | Typical Source |

|---|---|---|

| Connected Load (kW) | Sum of all equipment ratings | Equipment schedule |

| Demand Factor | Ratio of maximum demand to connected load | Historical or design estimate |

| Diversity Factor | Reflects non-simultaneous operation | Load study |

| Power Factor | Average operating power factor | Utility data or measurement |

| Voltage Level | Primary and secondary voltage | System design |

| Ambient Temperature | Site environmental condition | Site survey |

| Cooling Method | ONAN, ONAF, etc. | Specification requirement |

Start using our online tool today — it’s free Transformer Short Circuit Calculator – Accurate Fault Current & Transformer Protection Tool

Accurate collection of these inputs ensures transformer sizing calculation as per IEC reflects real operating conditions rather than theoretical assumptions.

Step-by-Step Load Assessment

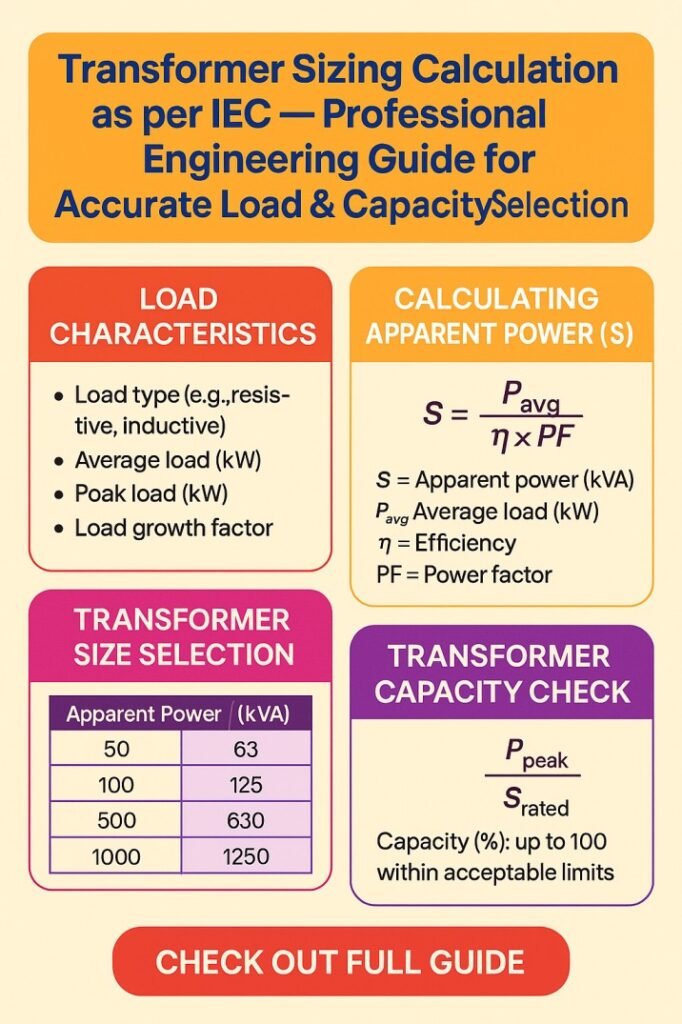

The first stage of transformer sizing calculation as per IEC involves evaluating the maximum demand load. Begin by summing connected loads and applying demand and diversity adjustments.

Real power demand can be estimated as:

Maximum Demand (kW) = Connected Load × Demand Factor

Apparent power requirement becomes:

kVA Required = Maximum Demand ÷ Power Factor

Use our online tool without paying anything Transformer Impedance Calculation Tool – Accurate Transformer Impedance Calculator for Engineers

This step ensures transformer sizing calculation as per IEC accounts for reactive power flow, not just real energy consumption. In installations with motor loads or variable frequency drives, include harmonic considerations and power factor correction when refining estimates.

Table 2 shows an example of load grouping used in transformer sizing calculation as per IEC.

| Load Category | Connected Load kW | Demand Factor | Adjusted Load kW |

|---|---|---|---|

| Motors | 250 | 0.75 | 187.5 |

| Lighting | 60 | 0.90 | 54 |

| HVAC | 120 | 0.80 | 96 |

| Miscellaneous | 70 | 0.70 | 49 |

| Total | 500 | — | 386.5 |

If the average power factor is 0.9, the calculated apparent power equals approximately 430 kVA. This intermediate result feeds directly into transformer sizing calculation as per IEC.

Access our online tool completely free Transformer Vector Group Calculation Tool | Easy & Accurate Vector Group Calculator

Applying Safety Margin and Future Growth

IEC-based engineering practice recommends incorporating margin for unforeseen expansion and temperature rise limitations. Transformer sizing calculation as per IEC generally adds a capacity allowance between 10% and 25%, depending on load volatility and project planning horizon.

Adjusted Transformer Rating:

Selected kVA = Calculated kVA × Margin Factor

Using the previous example with a 20% allowance:

Selected kVA ≈ 430 × 1.2 = 516 kVA

The engineer then selects the next standard rating, such as 630 kVA, ensuring compliance with transformer sizing calculation as per IEC and available manufacturer standards.

Consideration of Environmental Derating

Ambient conditions significantly affect transformer capability. Transformer sizing calculation as per IEC includes temperature and altitude correction because heat dissipation and dielectric strength change with environment.

Use our tool online at no cost Transformer Losses Calculation Tool – Accurate & Easy Energy Loss Analysis

Table 3 illustrates typical temperature correction guidance.

| Ambient Temperature | Recommended Adjustment |

|---|---|

| Up to 30°C | No derating |

| 35°C | Reduce loading by 2% |

| 40°C | Reduce loading by 5% |

| Above 45°C | Detailed thermal review required |

Ignoring environmental impact may result in selecting a unit incapable of sustaining rated load. Proper transformer sizing calculation as per IEC therefore verifies final capacity against installation conditions.

Voltage Regulation and Impedance Check

Another aspect of transformer sizing calculation as per IEC involves ensuring acceptable voltage drop under load. High impedance values may cause excessive regulation issues in long feeders or motor starting conditions. Reviewing percentage impedance and short circuit capacity ensures network stability.

Engineers performing transformer sizing calculation as per IEC also coordinate transformer impedance with downstream protection systems. This ensures circuit breakers and relays operate within fault current limits.

Try our free online tool Transformer Temperature Rise Calculator: Accurate and Easy Guide

Efficiency and Loss Evaluation

IEC standards emphasize loss evaluation for lifecycle cost analysis. Transformer sizing calculation as per IEC considers no-load and load losses to estimate operational efficiency. Selecting a slightly higher rating may reduce copper loss during typical operation, improving overall efficiency.

Table 4 provides indicative efficiency ranges.

| Transformer Rating | Typical Efficiency at Full Load |

|---|---|

| Up to 100 kVA | 96–97% |

| 250–500 kVA | 97–98% |

| Above 1 MVA | 98–99% |

Evaluating efficiency during transformer sizing calculation as per IEC supports energy management targets and sustainability planning.

Use our online tool for free Transformer Neutral Current Calculator – Accurate Neutral Current Estimation

Practical Example Summary

To illustrate transformer sizing calculation as per IEC in a simplified workflow:

- Gather connected load data and site conditions

- Apply demand and diversity adjustments

- Convert kW to kVA using system power factor

- Add safety margin and future expansion factor

- Adjust for temperature or altitude derating

- Select nearest standard rating

- Verify impedance, regulation, and efficiency

Following these steps ensures transformer sizing calculation as per IEC produces technically sound and economically balanced selections.

Common Engineering Mistakes to Avoid

Even experienced designers occasionally overlook critical aspects during transformer sizing calculation as per IEC. Frequent issues include neglecting harmonic loads, ignoring seasonal temperature extremes, or assuming unity power factor. Another common mistake is bypassing diversity evaluation, leading to inflated ratings and increased project cost.

A disciplined approach to transformer sizing calculation as per IEC prevents these issues. Incorporating measurement data from similar installations and consulting manufacturer thermal curves further enhances accuracy.

Read in detail about types of transformer protection relays

Conclusion

Accurate transformer capacity selection is fundamental to power system reliability and efficiency. Applying transformer sizing calculation as per IEC provides a structured path from raw load data to final equipment rating while respecting thermal, electrical, and environmental constraints. By carefully evaluating demand, adding reasonable margin, and verifying operating conditions, engineers can ensure long service life and stable system performance.

Consistent application of transformer sizing calculation as per IEC not only strengthens compliance with international standards but also optimizes investment decisions across industrial facilities, renewable plants, and commercial infrastructure. Mastering this methodology enables professionals to deliver installations that are robust, efficient, and ready for future growth.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerSizingCalculation, #IECStandards, #PowerTransformerDesign, #ElectricalEngineering, #LoadCalculation, #TransformerSelection, #PowerSystemDesign, #EngineeringGuide, #ElectricalCalculations, #EnergyInfrastructure