Test Link in Lightning Protection – NEC-Compliant Design, Installation, and Inspection Guide for Professionals

A properly designed lightning protection system is only as reliable as its ability to be inspected and tested over time. That is where the test link in lightning protection becomes a critical component for engineers, contractors, and inspectors. This small but essential fitting allows safe disconnection of the grounding path so resistance measurements and continuity checks can be performed without dismantling the entire system. In professional installations, the presence of a test link in lightning protection is not just good practice, it supports compliance, maintenance, and long-term safety.

Table of Contents

What Is a Test Link and Why It Matters

A test link is a removable connection installed in the down conductor path, usually just above ground level. It allows the grounding electrode system to be isolated for testing. Without it, verifying earth resistance or checking conductor integrity becomes difficult and sometimes unsafe.

In any test link in lightning protection design, the goal is to balance accessibility with mechanical strength and corrosion resistance. The link must remain secure during a lightning event yet be easy to open during inspection. This is especially important in commercial and industrial buildings where periodic testing is part of facility maintenance programs.

Know more about What Is Early Streamer Emission A Practical Guide for Engineers, Standards, and Lightning Protection Design

From a code perspective, lightning protection systems are primarily covered by NFPA 780 and UL 96A, while the NEC focuses on grounding, bonding, and surge protection. However, the test link in lightning protection plays a role in NEC-related requirements by supporting proper grounding electrode connections and bonding verification.

NEC-Relevant Design Considerations

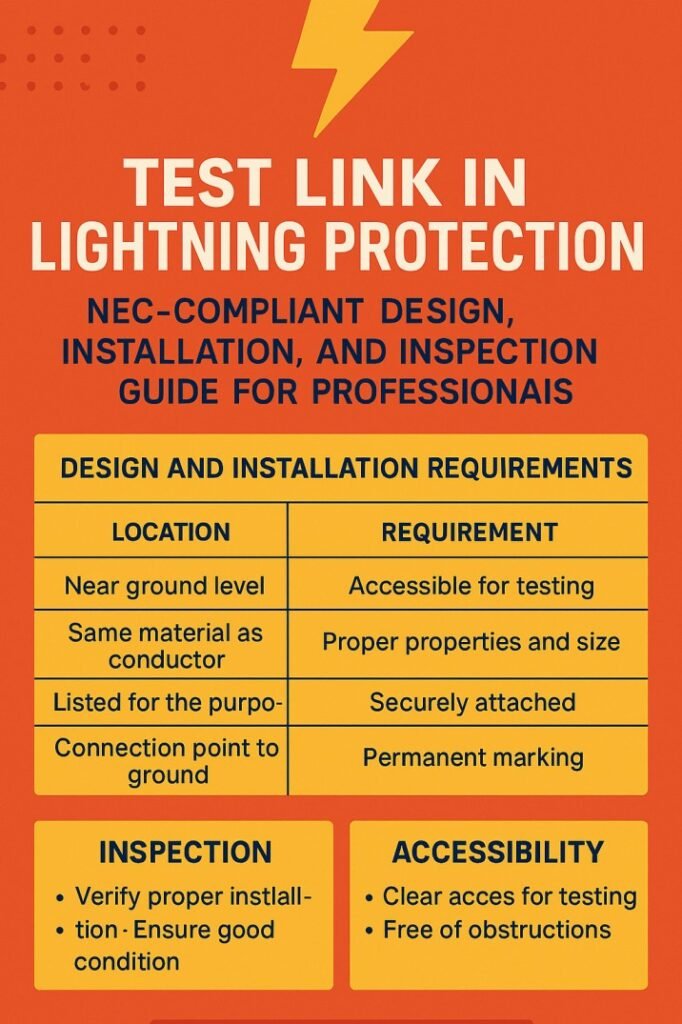

Although the NEC does not prescribe lightning protection layouts in detail, it does regulate grounding and bonding interfaces. When integrating a test link in lightning protection, designers should ensure the following:

- Bonding between the lightning system and the building grounding electrode system follows NEC Article 250

- Connections to structural steel or concrete-encased electrodes are accessible for inspection

- Surge protective devices connected under NEC Article 285 reference a properly bonded grounding system

- The lightning down conductor routing avoids sharp bends and maintains mechanical protection

Placement is also important. The test link in lightning protection should be installed:

- At a height that prevents accidental contact

- In a visible and accessible location for inspectors

- Away from areas prone to physical damage or vehicle impact

Know more about What Is Air Terminal in Lightning Protection? Function, Types & Installation Explained

Typical Components Around a Test Link

The test link does not exist in isolation. It is part of a complete path from air terminal to earth termination.

| Component | Function | Installation Tip |

|---|---|---|

| Air terminal | Captures lightning strike | Mount at roof high points |

| Down conductor | Carries current to ground | Keep path straight and direct |

| Test link | Allows disconnection for testing | Install above finished grade |

| Ground electrode | Dissipates current into soil | Use multiple electrodes if soil resistivity is high |

| Bonding conductor | Equalizes potential between systems | Bond to building grounding electrode system |

Each of these parts must work together. If the test link in lightning protection is poorly installed, accurate resistance testing becomes impossible and hidden corrosion may go undetected.

Installation Best Practices

Field installation determines whether the system will pass inspection later. A correctly installed test link in lightning protection should meet these practical guidelines:

- Use listed and labeled connectors compatible with copper or aluminum conductors

- Apply anti-corrosion compounds where dissimilar metals meet

- Ensure all bolted connections are tightened to manufacturer torque values

- Provide a protective cover if installed in public or high-traffic areas

- Label the location so maintenance teams can easily identify it

Installers should avoid embedding the link in concrete or burying it below grade. Accessibility is essential for future testing and verification. Know more about Types of Lightning Arrester Explained: Important Guide for Power Systems & Substations

Inspection and Testing Procedures

Periodic inspection is where the test link in lightning protection proves its value. By opening the link, technicians can isolate the grounding electrode system and perform accurate earth resistance measurements using fall-of-potential or clamp-on testing methods.

A standard inspection may include:

- Visual check for corrosion, loose hardware, or mechanical damage

- Continuity test of down conductors and bonding jumpers

- Ground resistance measurement of the electrode system

- Verification that bonding to building grounding remains intact

Testing should be documented, especially for critical facilities such as data centers, hospitals, and industrial plants. The presence of a test link in lightning protection makes these procedures faster and more reliable.

Know more about Leakage Current in Lightning Arrester: Best Guide

| Inspection Item | What to Look For | Recommended Frequency |

|---|---|---|

| Mechanical condition | Tightness, corrosion, damage | Annually |

| Conductor continuity | Low resistance path | Every 1–2 years |

| Ground resistance | Stable, within design limits | Every 2–3 years |

| Bonding connections | Secure and intact | During major electrical work |

Common Design and Installation Mistakes

Even experienced teams make avoidable errors with grounding hardware. The most common issues involving a test link in lightning protection include:

- Installing the link too close to grade where water and soil accelerate corrosion

- Hiding the connection behind walls or landscaping

- Using non-listed clamps that loosen over time

- Failing to bond the lightning grounding system to the building grounding electrode system

- Skipping periodic testing because access is inconvenient

These mistakes reduce system reliability and may lead to non-compliance with inspection standards or insurance requirements.

Know more about Earth Cable Size for Lightning Protection

Coordination with Other Building Systems

Modern facilities contain multiple grounding networks for power, data, and equipment protection. The test link in lightning protection helps verify that all these systems are properly bonded without creating unintended ground loops. Coordination between electrical engineers, lightning protection specialists, and inspectors ensures that grounding electrodes, structural steel, and surge protection all share a common reference point.

This coordination improves safety, reduces side flashes, and limits damage to sensitive electronics during a lightning event.

Know more about IEC Standard for Lightning Protection: A Complete Technical Guide

Final Thoughts for Professionals

A lightning protection system is not a set-and-forget installation. Ongoing verification is part of professional responsibility, and the test link in lightning protection is central to that process. It supports safe testing, simplifies inspections, and strengthens code compliance related to grounding and bonding. When properly designed, installed, and maintained, this simple component plays a major role in ensuring the entire system performs when it is needed most.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#LightningProtection, #ElectricalEngineering, #GroundingSystems, #SurgeProtection, #NECStandards, #EarthingDesign, #ElectricalSafety, #PowerSystems, #BuildingCodes, #IndustrialElectrical