Rolling Sphere Method for Lightning Protection: Code-Compliant Design, Sizing, and Standards Guide for Engineers

The Rolling Sphere Method for Lightning Protection is one of the most reliable ways to evaluate whether a structure is properly shielded from direct lightning strikes. Many protection failures happen not because equipment is missing, but because placement and geometry were not checked against real lightning attachment behavior. Engineers who understand the Rolling Sphere Method for Lightning Protection can design systems that meet international codes while improving safety and performance in the field.

Table of Contents

Lightning does not strike randomly. It follows predictable electrical paths based on leader formation and electric field intensity. The Rolling Sphere Method for Lightning Protection models this behavior using a geometric approach that simulates how a downward lightning leader connects with objects on the ground. This makes it a practical engineering tool rather than just a theoretical concept.

Understanding the Physics Behind the Method

The Rolling Sphere Method for Lightning Protection is based on the concept of strike distance. Strike distance is the final gap a lightning leader can jump before attachment. Taller or sharper objects reduce this gap, which is why towers, air terminals, and roof edges are common strike points.

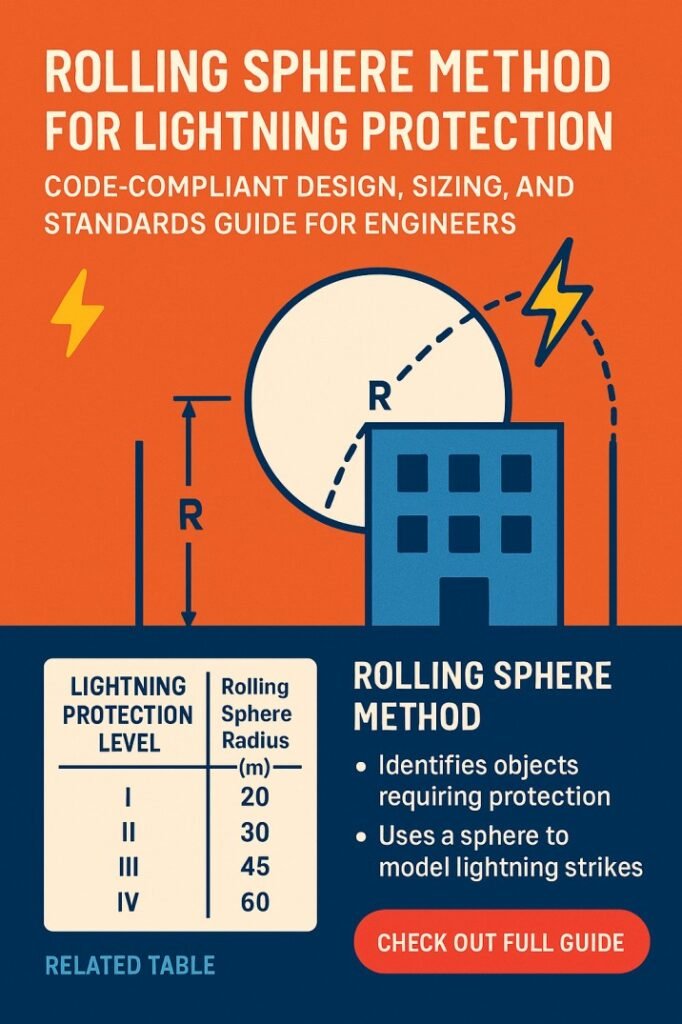

In this method, an imaginary sphere is rolled over and around a structure. Wherever the sphere touches, that point is vulnerable to a lightning strike. If a lightning protection component prevents the sphere from touching the structure, that area is considered protected.

The radius of the sphere represents the strike distance and is linked to the lightning protection level (LPL). Higher protection levels use smaller sphere radii, meaning stricter protection requirements.

Know more about What Is Early Streamer Emission A Practical Guide for Engineers, Standards, and Lightning Protection Design

Standard Sphere Radii from International Codes

Different standards define sphere sizes depending on risk level. The Rolling Sphere Method for Lightning Protection is formally described in IEC 62305 and referenced in NFPA 780.

| Lightning Protection Level | Sphere Radius (m) | Typical Application |

|---|---|---|

| LPL I | 20 m | High-risk sites, explosive areas |

| LPL II | 30 m | Critical facilities, hospitals |

| LPL III | 45 m | Commercial buildings |

| LPL IV | 60 m | Low-risk structures |

Smaller radii create more conservative designs because the sphere can reach deeper areas of a structure. This ensures air termination systems cover more vulnerable zones.

Why Engineers Prefer This Method

The Rolling Sphere Method for Lightning Protection is widely used because it reflects real lightning behavior better than simple angle methods. It works especially well for complex geometries such as industrial plants, telecom towers, and buildings with rooftop equipment.

Key advantages include:

- Suitable for irregular roof shapes and varying heights

- Compatible with 3D modeling and CAD tools

- Directly linked to international lightning protection standards

- Helps optimize air terminal placement and quantity

Because lightning attachment is three-dimensional, this method gives a more realistic protection envelope than older, simplified rules.

Know more about What Is Air Terminal in Lightning Protection? Function, Types & Installation Explained

Step-by-Step Application in Design

Applying the Rolling Sphere Method for Lightning Protection starts with defining the required lightning protection level. This comes from a risk assessment based on occupancy, structure type, and local lightning density.

The general workflow is:

- Select the required LPL from IEC 62305 risk calculation

- Use the corresponding sphere radius

- Roll the sphere over the structure model in all directions

- Identify contact points between sphere and structure

- Install air terminals or masts to block sphere contact

- Recheck until all critical areas are shielded

Modern lightning protection design software automates sphere rolling, but field engineers should still understand the geometry behind the results.

Air Terminals and Mast Height Selection

Air terminals, also called lightning rods, are the primary interception devices. Their height directly influences the protection zone created under the Rolling Sphere Method for Lightning Protection.

| Mast Height (m) | Approximate Additional Protected Radius (m)* |

|---|---|

| 2 | Limited local protection |

| 5 | Suitable for small rooftop equipment |

| 10 | Effective for medium roof areas |

| 20 | Large protection envelope for open sites |

*Actual protection depends on sphere radius and surrounding geometry.

Know more about Earth Cable Size for Lightning Protection

Increasing mast height expands coverage but also increases mechanical loading and cost. Engineers must balance electrical protection with structural design and wind loading.

Protecting Rooftop Equipment

Rooftop HVAC units, solar panels, antennas, and cable trays often sit outside simple protection zones. The Rolling Sphere Method for Lightning Protection is essential for checking these installations.

Common solutions include:

- Installing dedicated air terminals near sensitive equipment

- Using elevated masts to create a wider protection envelope

- Bonding metal frames into the lightning protection system

- Ensuring proper separation distance from internal wiring

Failure to protect rooftop systems is a leading cause of surge damage and downtime. Know more about Types of Lightning Arrester Explained: Important Guide for Power Systems & Substations

Down Conductors and Grounding Integration

The Rolling Sphere Method for Lightning Protection only addresses interception. A complete lightning protection system also requires safe current dissipation through down conductors and grounding electrodes.

Best practices include:

- Multiple down conductors spaced evenly around the structure

- Direct, low-impedance paths to ground

- Ring earth electrodes or foundation grounding

- Equipotential bonding to reduce side flashes

Even perfect air terminal placement will not prevent damage if the grounding system cannot safely carry lightning current.

Know more about Leakage Current in Lightning Arrester: Best Guide

Comparison with Protection Angle Method

Some engineers still use the protection angle method because it is simple. However, it becomes inaccurate for taller structures.

| Method | Accuracy for Tall Structures | Suitable for Complex Geometry | Code Preference |

|---|---|---|---|

| Protection Angle Method | Low | Poor | Limited use |

| Rolling Sphere Method for Lightning Protection | High | Excellent | Widely required |

Most modern standards recommend the rolling sphere approach for heights above 20 meters or when rooftop equipment is present.

Use in Industrial and Hazardous Areas

The Rolling Sphere Method for Lightning Protection is critical in oil and gas plants, chemical facilities, and explosive storage areas. A direct strike in these environments can cause fires or catastrophic explosions.

Design considerations include:

- Higher protection levels (LPL I or II)

- Closer air terminal spacing

- Strict bonding of metal piping and tanks

- Spark gap or isolated down conductor systems

These sites often require third-party inspection to verify compliance with IEC and local regulations.

Know more about IEC Standard for Lightning Protection: A Complete Technical Guide

Software Modeling and Field Verification

Today, many engineers perform the Rolling Sphere Method for Lightning Protection using 3D design tools. These tools simulate sphere movement and automatically flag unprotected points.

However, field verification remains important:

- Confirm installed air terminal heights match design

- Check conductor routing and bonding

- Inspect grounding electrode connections

- Measure earth resistance where required

Installation errors can reduce protection effectiveness even if the design is correct.

Common Design Mistakes

Several recurring mistakes reduce system performance:

- Ignoring small rooftop projections like vents and railings

- Using insufficient mast height to reduce cost

- Forgetting protection for solar panel arrays

- Placing air terminals too close to sensitive cables

- Poor bonding between structural steel and LPS

Applying the Rolling Sphere Method for Lightning Protection carefully helps engineers catch these issues early in the design phase.

Know more about IEC Standard for Lightning Arrester – IEC 60099 Guide for Surge and Overvoltage Protection

Coordination with Surge Protection

Direct strike protection and surge protection must work together. While the Rolling Sphere Method for Lightning Protection reduces the chance of a direct hit, induced surges still travel through power and data lines.

Engineers should coordinate:

- Type 1 surge protective devices at service entrances

- Bonding between lightning protection and electrical grounding

- Shielding and routing of communication cables

This layered approach provides both structural and equipment safety.

Final Thoughts for Practicing Engineers

The Rolling Sphere Method for Lightning Protection is not just a code requirement. It is a practical design philosophy grounded in lightning physics. When applied correctly, it reduces risk, prevents equipment loss, and protects lives.

Know more about Top 10 Lightning Protection Design Softwares: Best Guide

Engineers who combine proper sphere analysis with good grounding, bonding, and surge protection create systems that perform reliably during real storms. Whether designing a commercial building, telecom tower, or industrial plant, mastering the Rolling Sphere Method for Lightning Protection ensures your lightning protection system is both compliant and effective.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#LightningProtection, #RollingSphereMethod, #NFPA780, #IEC62305, #EarthingAndBonding, #SurgeProtection, #ElectricalDesign, #PowerSystemProtection, #GroundingSystem, #ElectricalStandards