Overload Relay for Motor: A Complete Guide

What is an Overload Relay for Motor?

An overload relay for motor is a protective device that prevents electric motors from overheating due to excessive current flow. It ensures motor safety by disconnecting power when the current surpasses a set threshold for a specific duration. This protection is essential to extend the motor’s lifespan and maintain operational efficiency.

Overload relays work by sensing abnormal conditions and triggering a disconnection before damage occurs. They are commonly used in industrial and commercial applications where motors drive machinery, pumps, fans, and conveyors.

Table of Contents

Table of Contents

What is Thermal Overload?

Thermal overload occurs when a motor experiences excessive heat due to high current or prolonged operation. If left unchecked, thermal overload can lead to insulation breakdown, winding damage, and even motor failure.

A thermal overload relay prevents such issues by measuring temperature rise and tripping the circuit when necessary.

What is an Overload Relay for Motor?

An overload relay is an electrical device that protects motors from excessive current by breaking the circuit when necessary. Unlike fuses or circuit breakers that respond to short circuits, overload relays focus on prolonged high-current situations that generate heat.

Overload relays are installed in motor control circuits and work alongside contactors to ensure safe motor operation.

Learn More About Differences in Bimetal Overload and Ambient-Compensated Overload Relays

Importance of Overload Relays

Electric motors typically draw a significantly higher current during startup—up to six times their full-load current rating. While they can tolerate this surge for a brief period, prolonged overload can lead to overheating and permanent damage. Unlike fuses and circuit breakers, which are designed for general overcurrent protection, overload relays specifically cater to the unique demands of motors by allowing temporary overloads during startup while providing protection against sustained overloads

How Overload Relays Work

Overload relays monitor the current flowing through the motor circuit. When the current exceeds a predetermined threshold for a specified duration, the relay trips, interrupting the power supply to the motor. This action prevents overheating and potential motor failure.

Bimetallic Strips: These strips consist of two different metals that expand at different rates when heated. As current flows through the strip, it heats up; if the temperature exceeds a certain point due to excessive current, the strip bends and trips the relay.

Magnetic Detection: Some overload relays use magnetic fields generated by the current flow to detect overload conditions. This method is less sensitive to temperature changes and can be more reliable in varying ambient conditions.

Trip Classes

Overload relays are categorized into trip classes (e.g., Class 10, Class 20, Class 30), which indicate how long they will allow an overload condition before tripping. For instance:

- Class 10: Trips after 10 seconds of overload.

- Class 20: Trips after 20 seconds.

- Class 30: Trips after 30 seconds.

Types of Overloads

Overloads in motors can be categorized based on their cause:

Electrical Overload – Occurs when excessive current flows through the motor due to increased load demand.

Mechanical Overload – Happens when a motor drives a load beyond its rated capacity, causing excessive torque and current draw.

Thermal Overload – Results from overheating due to inadequate ventilation, high ambient temperature, or extended operation.

Types of Overload Relays for Motor

Overload relays can be classified into different types based on their operating principle:

Thermal Overload Relay – Uses a thermal overload relay symbol to indicate its function in circuit diagrams. It operates based on heat generation and is widely used in industrial motor protection.

Electronic Overload Relay – Uses advanced microprocessor technology for precise motor protection. It offers adjustable settings and real-time monitoring.

Magnetic Overload Relay – Works based on electromagnetic force and is commonly used in fast-acting protection systems.

The two classifications of overload relays are thermal and electronic, with each having specific applications based on precision and response time.

Thermal Overload Relays

Thermal overload relays are among the most commonly used protection devices in motor circuits. They contain bimetallic strips that bend when exposed to excessive heat, causing the relay to trip and disconnect power.

Thermal Overload Relay Symbol and Diagram

The thermal overload relay symbol represents its role in motor protection circuits. A thermal overload relay diagram typically includes:

- Motor connections

- Overload sensing elements

- Trip mechanisms

- Reset options

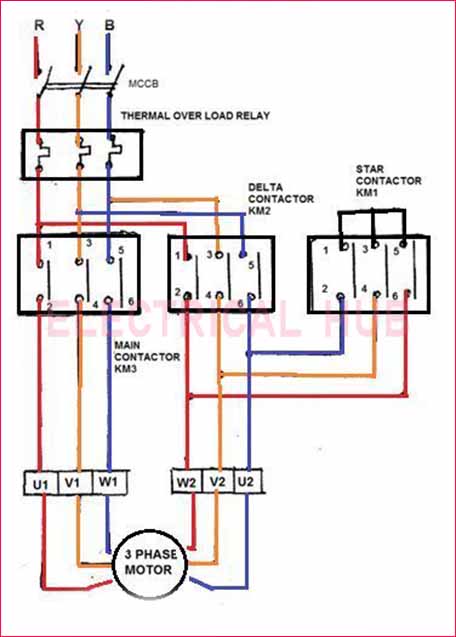

The symbol of Thermal overload can be seen in the star delta starter diagram.

This diagram helps technicians understand relay operation and ensure proper installation.

Thermal Overload Protection

Thermal overload protection is critical in preventing motor failure due to overheating. This protection method ensures that a motor operates within safe temperature limits.

A thermal overload switch symbol is often used in electrical schematics to indicate devices that safeguard motors from excessive heat. like explained above.

Sizing Overloads for Motors

Correctly sizing overloads for motors is crucial to ensuring effective protection. The following factors are considered:

Motor Full Load Current (FLC): Overload relays should be set between 115% and 125% of the FLC.

Ambient Temperature: Adjustments may be required for extreme conditions.

Startup Characteristics: Motors with high inrush currents need specially designed overload relays.

Proper overload relay selection ensures that motors operate efficiently without unnecessary tripping.

Thermal Overload Motor Protection

A thermal overload motor system integrates protective devices to prevent excessive heat buildup. Thermal relays are used to monitor temperature and disconnect the motor when required.

Conclusion

An overload relay for motor is an essential protective device that ensures motor safety by preventing excessive current and heat buildup. Understanding types of overload relays, thermal overload protection, and sizing overloads for motors helps in selecting the right relay for efficient motor operation.

Related Posts:

- What is star delta starter

- Star Delta Starter Diagram with Timer

- Overload Setting for Motor

- Difference Between Star Delta and DOL Starter

- Cable Size for Motor Calculator

- Induction Motor

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

OverloadRelay #MotorProtection #ThermalRelay #ElectricalEngineering #MotorSafety #OverloadProtection #IndustrialAutomation #ElectricalMaintenance #MotorControl #EngineeringTips #RelayDiagram #ThermalOverload #MotorOverload #ElectricMotors #AutomationTechnology