Overcurrent Protection of Transformer: A Complete Technical Guide

Transformers are vital assets in electrical power systems. Their uninterrupted operation ensures smooth power distribution in industrial, commercial, and residential networks. However, transformers are vulnerable to faults, and one of the most common threats is overcurrent. That’s why overcurrent protection of transformer is critical to maintain system reliability and safety.

This article offers a complete overview of transformer overcurrent protection. It includes technical insights, protective schemes, and industry best practices.

What Is Overcurrent Protection of Transformer?

Overcurrent protection of transformer refers to the measures taken to prevent excessive current flow that may damage the transformer windings, insulation, or connected systems. These protections ensure safe disconnection during abnormal current conditions like short circuits or prolonged overloads.

Transformers do not generate current themselves, but they pass on whatever current is demanded by the load. When the load current exceeds safe limits, protective devices must act to isolate the transformer from the system.

Learn more about What are the Three Types of Overcurrent?

Why Is Overcurrent Protection of Transformer Essential?

Transformers are expensive and not easily replaceable components. They need robust protection schemes for the following reasons:

- Prevent thermal and mechanical stress on windings

- Minimize insulation damage due to overheating

- Isolate faults to prevent cascading failures

- Enhance service life and reduce maintenance costs

- Comply with IEC standards for protection relays

In many installations, the PI Test of Transformer Procedure is performed before commissioning to ensure insulation integrity. However, during actual operation, overcurrent protection of transformer becomes the first line of defense.

Types of Overcurrent Affecting Transformers

Understanding the types of overcurrent is essential to design effective protection:

| Type of Overcurrent | Description | Typical Cause |

|---|---|---|

| Overload Current | Slightly higher than rated load current | Prolonged high-demand operation |

| Short-Circuit Current | Sudden large current surge | Phase-to-phase or phase-to-ground faults |

| Inrush Current | Initial magnetizing current | Transformer energization |

| Through Fault Current | Fault on load side of transformer | Fault downstream of transformer secondary |

Each type affects the transformer differently. Therefore, protection schemes must distinguish between temporary inrush and damaging faults.

Learn more about Motor Overload Setting Table

Overcurrent Protection Devices Used in Transformers

Several protective devices and relays are used to detect and isolate overcurrents. These include:

- Overcurrent relays (OCR): Simple and widely used. They trip when current exceeds preset value.

- Inverse time overcurrent relays (IDMT): Provide time delay depending on current magnitude.

- Differential relays: Compare incoming and outgoing currents. Any imbalance suggests internal fault.

- Buchholz relay: Detects gas accumulation in oil-filled transformers.

- Fuses: Fast-acting protection, commonly used in smaller transformers.

While differential relay in transformer systems protects against internal winding faults, overcurrent relays target external faults and overloads.

Settings for Overcurrent Protection of Transformer

To avoid unnecessary tripping during inrush or minor overloads, protection settings must be precise. Consider the following when setting up an OCR:

| Parameter | Typical Setting |

|---|---|

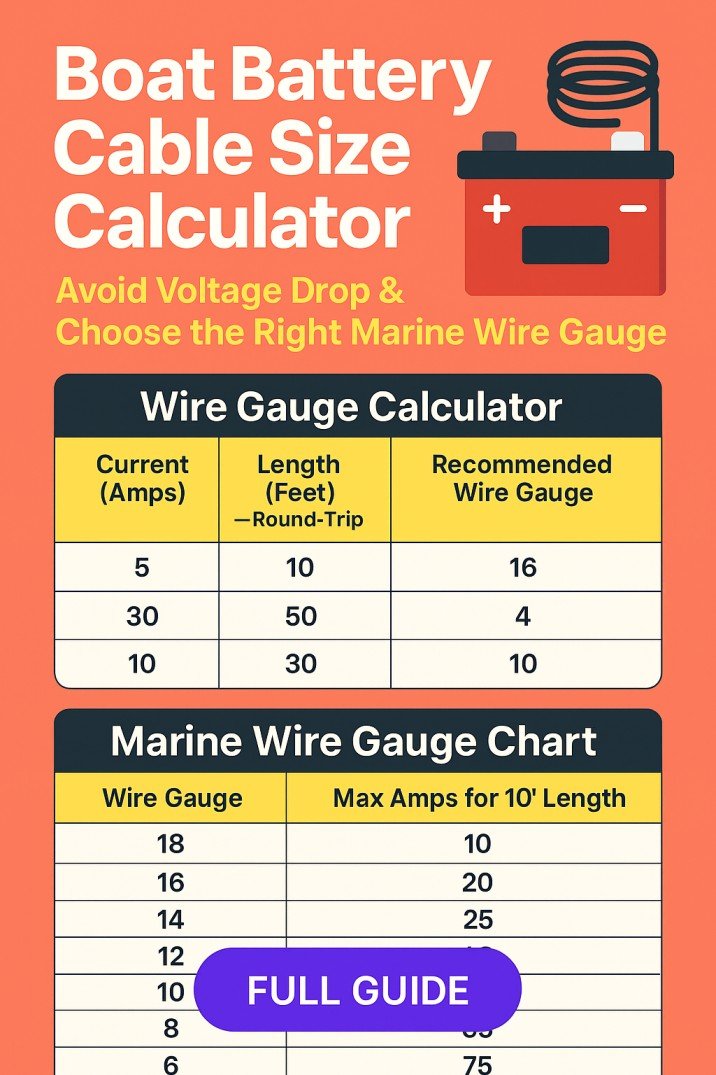

| Pickup Current | 125–150% of rated current |

| Time Delay | 0.5 to 2 seconds (based on coordination) |

| Instantaneous Setting | Above maximum expected fault current |

Settings are chosen based on transformer size, cooling method, fault level, and coordination with downstream breakers. Detailed differential relay calculation also plays a role when both overcurrent and differential protections are combined.

Learn more about IEC Standard for Protection Relays

Coordination of Overcurrent Protection with System

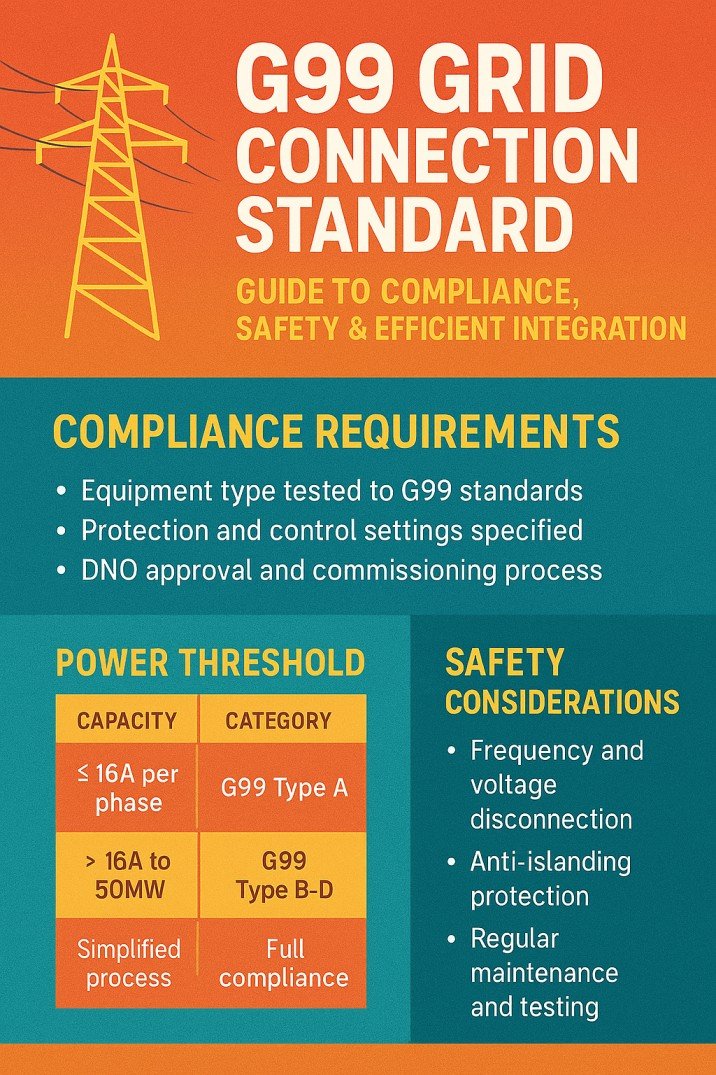

One of the most critical aspects of transformer protection is relay coordination. Overcurrent protection should be coordinated with upstream and downstream devices to avoid nuisance trips.

For example, in a radial system, the downstream circuit breaker should trip before the upstream OCR. This ensures only the faulted section is isolated. Use time-current characteristic (TCC) curves for precise coordination.

Proper relay grading is also required when multiple relays protect a common bus or feeder. In some cases, high impedance differential protection is used for sensitive and stable protection of transformers.

Key Features of Overcurrent Relays

Modern digital overcurrent relays offer advanced features:

- Programmable settings for time and current

- Communication protocols for SCADA integration

- Multiple protection elements (e.g., over/under voltage, frequency)

- Self-diagnostics and event recording

- Compliance with IEC 60255 — the IEC standard for protection relays

These smart relays improve system reliability and support data-driven maintenance.

Learn more about Motor Protection Circuit Breaker vs Overload Relay

Choosing the Right Overcurrent Protection Scheme

The selection depends on various factors:

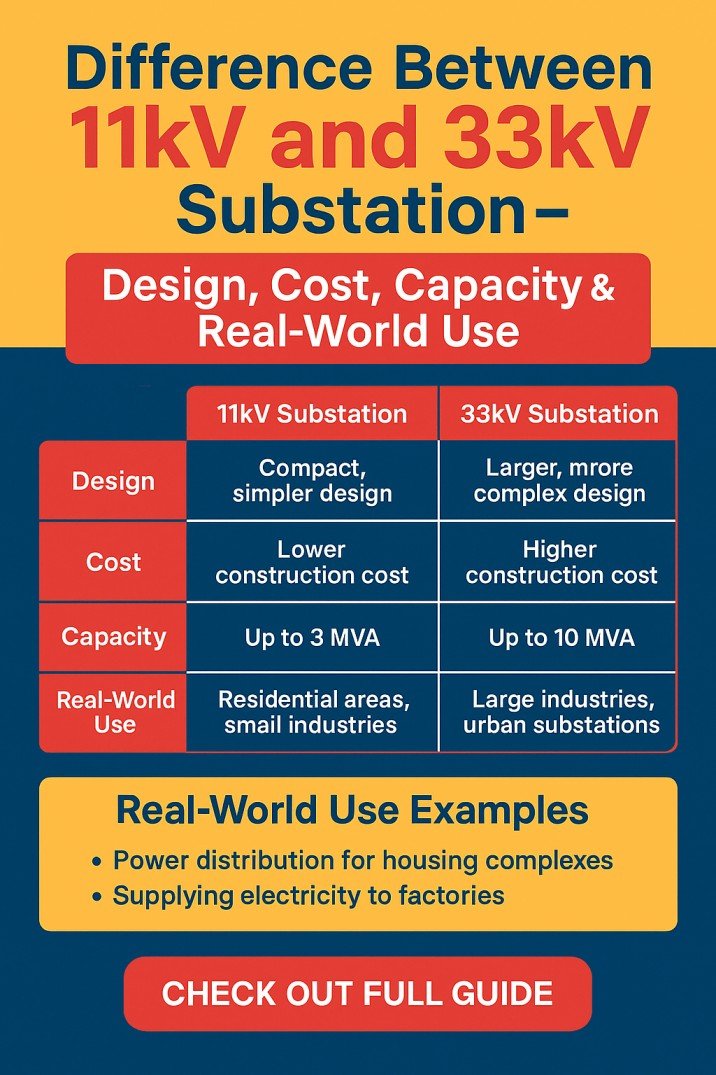

- Transformer capacity (kVA or MVA)

- Voltage levels (distribution or sub-transmission)

- System grounding (solid, resistance, or isolated)

- Availability of differential protection

- System configuration (radial, ring, or meshed)

Here is a simple decision table:

| Transformer Type | Recommended Protection |

|---|---|

| Small (<1 MVA) | Fuses or basic OCR |

| Medium (1–10 MVA) | IDMT relay + earth fault protection |

| Large (>10 MVA) | Differential relay + backup OCR |

In critical applications like hospitals or data centers, dual protection with backup relays is common.

Transformer Inrush and Overcurrent Relay Behavior

One challenge with overcurrent protection of transformer is the transformer inrush current. When a transformer is first energized, it draws 6–10 times its rated current. However, this is not a fault.

Overcurrent relays must avoid tripping during this brief period. Two common methods used:

- Inrush blocking: Relay blocks tripping for a short duration

- 2nd harmonic restraint: Detects magnetizing inrush using harmonic analysis

Advanced relays use both techniques to enhance stability.

Learn more about IEC 62368 1 Leakage Current

Common Challenges and Solutions

Let’s look at frequent protection issues and how to resolve them:

| Challenge | Solution |

|---|---|

| Nuisance tripping during energization | Use inrush blocking or 2nd harmonic restraint |

| Inadequate coordination | Adjust time settings and grading |

| Protection failure during high impedance fault | Use sensitive differential relay in transformer |

| Overload without trip | Reduce pickup setting or enable thermal elements |

| Earth fault not detected | Add separate ground fault relay element |

Maintenance of Overcurrent Protection Devices

Routine maintenance ensures reliable operation. Key steps include:

- Checking trip settings and calibration

- Verifying time-current curves

- Testing relay response using secondary current injection

- Recording relay status in SCADA system

- Inspecting CTs and wiring for continuity and insulation

Regular testing as per IEC standard for protection relays helps avoid operational failures.

Conclusion

Overcurrent protection of transformer is not just about placing a relay in the circuit. It’s a calculated process that considers transformer behavior, system configuration, and fault dynamics. A well-designed scheme prevents damage, minimizes downtime, and ensures system resilience.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#OvercurrentProtection, #TransformerProtection, #ElectricalEngineering, #PowerTransformer, #TransformerSafety, #ElectricalFaults, #ProtectionRelay, #OverloadProtection, #ShortCircuitProtection, #TransformerDesign, #ElectricalSystems, #TechGuide, #EngineeringInsights, #PowerSystemProtection, #SubstationSafety