NEC Article 310 Explained: Ampacity Rules, Wire Sizing & Code Secrets Electricians Must Know

Understanding nec article 310 is essential for anyone working with electrical installations. Whether you are designing a new system or upgrading an existing one, conductor ampacity and proper wire sizing directly impact safety, performance, and code compliance. Many field issues, from overheating to failed inspections, trace back to misinterpreting nec article 310 requirements.

Table of Contents

This article breaks down the most important parts in a practical way. You will learn how ampacity is determined, how temperature ratings affect conductor sizing, and the real-world code rules electricians must apply every day.

What NEC Article 310 Covers

nec article 310 focuses on conductors for general wiring. It outlines how to select wires based on ampacity, insulation type, temperature rating, installation conditions, and correction factors. The goal is simple: prevent overheating and ensure long-term reliability.

In everyday work, nec article 310 affects:

- Feeder and branch circuit conductors

- Service entrance conductors

- Underground and raceway wiring

- Parallel conductor installations

It does not just tell you a wire size. It tells you the conditions that determine whether that wire size is safe.

Access our powerful online calculator now Conduit Fill Calculator (NEC Standard): Best Tool

Understanding Ampacity the Right Way

Ampacity is the maximum current a conductor can carry continuously without exceeding its temperature rating. nec article 310 provides ampacity tables that most electricians rely on, especially Table 310.16.

But those values are not always final. They are based on specific conditions:

- Ambient temperature of 30°C (86°F)

- No more than three current-carrying conductors in a raceway or cable

- Proper insulation rating

If your installation differs, you must apply correction and adjustment factors. This is where many mistakes happen when using nec article 310.

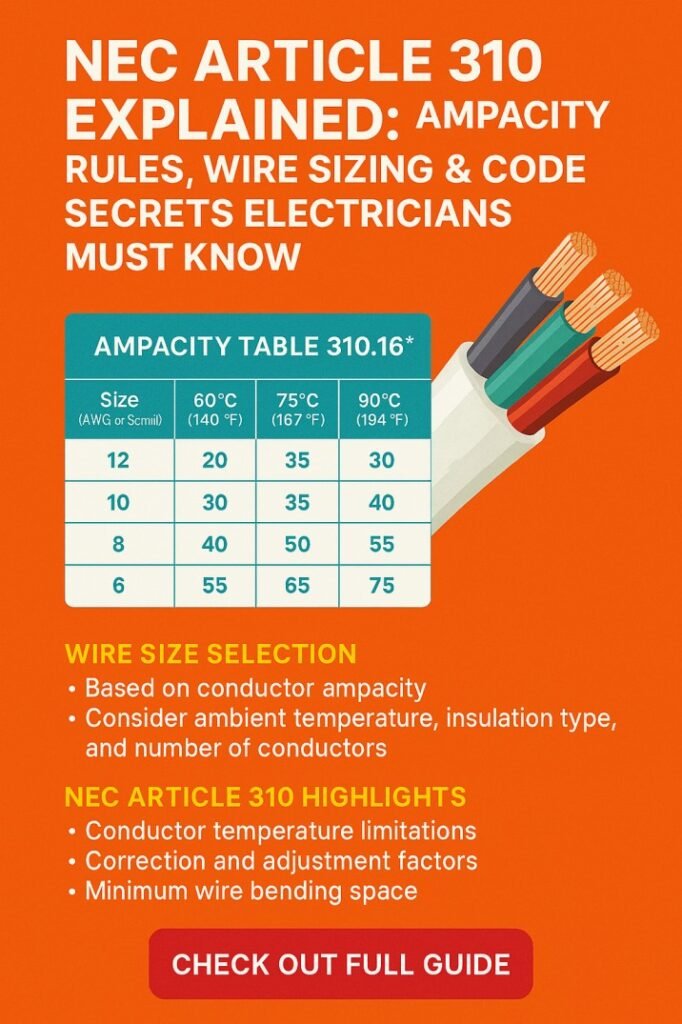

Common Copper Conductor Ampacities

| Conductor Size (AWG) | 60°C Rating | 75°C Rating | 90°C Rating |

|---|---|---|---|

| 14 AWG | 15A | 20A | 25A |

| 12 AWG | 20A | 25A | 30A |

| 10 AWG | 30A | 35A | 40A |

| 8 AWG | 40A | 50A | 55A |

| 6 AWG | 55A | 65A | 75A |

These values come directly from tables governed by nec article 310, but final allowable ampacity often depends on termination ratings.

Read in detail about nec 392.22

Temperature Ratings and Termination Limits

One of the most misunderstood parts of nec article 310 is the relationship between conductor insulation rating and termination temperature rating.

For example, a THHN conductor may be rated 90°C, but if it lands on a breaker rated only 75°C, you must use the 75°C ampacity column. The weakest point in the circuit determines the limit.

Key rules to remember:

- Equipment rated 100A or less usually uses 60°C or 75°C terminations

- Equipment over 100A often allows 75°C terminations

- The 90°C column is mainly used for derating calculations, not final ampacity

Ignoring this detail is a common reason inspectors reject installations that otherwise seem correct under nec article 310.

Know more about NEC Grounding Table 250.122 Explained: Correct Equipment Grounding Conductor Size

Adjustment Factors for Multiple Conductors

When more than three current-carrying conductors are installed together, heat builds up. nec article 310 requires ampacity adjustment in these cases.

Conductor Adjustment Factors

| Current-Carrying Conductors | Adjustment Factor |

|---|---|

| 4–6 | 80% |

| 7–9 | 70% |

| 10–20 | 50% |

| 21–30 | 45% |

| 31–40 | 40% |

Suppose you run nine current-carrying conductors in a raceway. According to nec article 310, you must multiply the conductor ampacity by 70 percent before selecting overcurrent protection.

Ambient Temperature Correction

High ambient temperatures also reduce ampacity. Rooftop conduits, boiler rooms, and outdoor installations often require correction.

nec article 310 provides temperature correction factors based on insulation type. For instance, a 90°C conductor in a 40°C environment must be derated before final ampacity is determined.

Understand better about nec 430.32

This is especially important in hot climates where ambient temperatures routinely exceed 30°C. Without applying these factors from nec article 310, conductors can overheat even under normal load.

Wire Sizing Process Step by Step

A safe and code-compliant sizing method based on nec article 310 looks like this:

- Determine the calculated load in amperes

- Select a conductor with sufficient base ampacity from the proper table

- Apply ambient temperature correction if required

- Apply adjustment factors for more than three current-carrying conductors

- Compare the corrected ampacity to termination temperature limits

- Select overcurrent protection based on the final allowable ampacity

Skipping any of these steps can result in undersized conductors that violate nec article 310.

Special Rules Electricians Often Miss

There are several field details in nec article 310 that are easy to overlook.

Neutral conductors do not always count as current-carrying. In balanced three-phase systems, a neutral that carries only unbalanced current may not require derating. However, in nonlinear loads with harmonics, the neutral often does count.

Explore everything about NEC Article 220: A Comprehensive Guide

Parallel conductors must be the same length, material, size, insulation type, and termination method. This rule from nec article 310 prevents uneven current sharing and overheating.

Underground conductors may have different ampacity limits depending on direct burial or conduit installation. Soil thermal resistivity can also affect performance, even though standard tables assume typical conditions.

Insulation Types and Their Impact

The insulation type affects both temperature rating and application. nec article 310 recognizes many conductor types used in the field.

Common examples include:

- THHN and THWN-2 for raceways

- XHHW and XHHW-2 for feeders and services

- USE-2 for underground service entrance

- RHW-2 for wet and dry locations

Each insulation type has specific wet or dry location ratings. Using the wrong type in a wet location is a violation of nec article 310 and can lead to insulation failure.

Discover all about NEC Code Practice Test: A Complete Guide to Boost Your Exam Success

Why Inspectors Focus on NEC Article 310

Inspectors often review conductor sizing first because it directly affects fire safety. Overheated conductors can damage insulation, cause arcing, and start electrical fires. That is why nec article 310 is one of the most enforced sections of the code.

Proper documentation also helps. Load calculations, derating steps, and conductor selections should be clear and traceable. When electricians show they followed nec article 310 correctly, inspections go more smoothly.

Practical Takeaways for the Field

To apply nec article 310 confidently on the job, keep these habits:

- Never rely only on the breaker size to choose wire

- Always check termination temperature ratings

- Count current-carrying conductors before pulling wire

- Watch for high ambient temperature locations

- Use the 90°C rating only for derating, not final ampacity

These simple practices prevent costly rework and improve system reliability.

Learn more about Demand Factor as Per NEC

Final Thoughts

Mastering nec article 310 is not about memorizing one table. It is about understanding how heat, environment, and installation methods affect conductor performance. When electricians apply these ampacity rules correctly, systems run cooler, safer, and more efficiently.

The more familiar you become with nec article 310, the faster and more accurate your wire sizing decisions will be. That knowledge translates directly into safer installations, fewer inspection issues, and a stronger professional reputation in the electrical industry.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#NECArticle310, #ElectricalCode, #AmpacityCharts, #WireSizing, #NEC2023, #ElectricalEngineering, #ConductorSizing, #CodeCompliance, #ElectricalDesign, #PowerDistribution