How to Calculate Earth Cable Size | Complete Electrical Grounding Calculation Guide

Designing a reliable earthing system is one of the most important responsibilities in electrical engineering. Proper grounding protects people, stabilizes system voltage, and ensures protective devices operate correctly during faults. Many engineers and technicians often ask how to calculate earth cable size because selecting the wrong conductor can lead to overheating, unsafe touch voltages, and equipment damage.

This guide explains how to calculate earth cable size using practical methods, real engineering considerations, and structured calculation steps that apply to industrial and commercial installations.

Table of Contents

Understanding how to calculate earth cable size begins with knowing the role of the earthing conductor. Unlike phase cables, it normally carries no current under healthy conditions. However, during a fault, it must safely carry high current for a short duration until the protection clears the fault. Because of this, sizing depends on thermal withstand capacity, fault level, conductor material, and installation standards rather than simple load current calculations.

Know more about Earth Cable Size for Lightning Protection

Understanding the Purpose of Earthing Conductors

Before discussing how to calculate earth cable size, it is useful to review what the conductor must achieve. The grounding cable connects exposed conductive parts to earth electrodes or the main earthing terminal. Its functions include ensuring fast disconnection of protective devices, maintaining low impedance paths, reducing step and touch potential, and protecting structures from transient overvoltages.

Engineers consider factors such as fault loop impedance, prospective short circuit current, conductor insulation rating, and environmental temperature. These aspects influence the thermal stress the conductor experiences when a fault occurs.

A simple overview of common conductor materials is shown below.

| Conductor Material | Electrical Conductivity | Thermal Capacity | Typical Use |

|---|---|---|---|

| Copper | Very high | Excellent | Industrial grounding and substations |

| Aluminum | Moderate | Good | Utility distribution grounding |

| Steel | Low | High mechanical strength | Earthing grids and structural bonding |

Material choice directly affects how to calculate earth cable size because the resistivity constant used in formulas differs between copper and aluminum.

Learn more about earthing cable size as per iec

Key Factors That Affect Earth Cable Sizing

When learning how to calculate earth cable size, engineers must evaluate several parameters instead of relying on assumptions. The most critical ones include fault current magnitude, clearing time of protective devices, conductor insulation limit, and installation method.

Fault current determines the thermal energy generated. Clearing time represents how long the conductor must carry that current. The allowable temperature rise depends on insulation and material characteristics. Installation environment affects cooling and mechanical protection.

The following table summarizes typical design parameters considered in grounding calculations.

| Parameter | Description | Importance in Sizing |

|---|---|---|

| Prospective fault current | Maximum expected earth fault current | Determines thermal stress |

| Fault duration | Time until breaker operates | Influences heat buildup |

| Initial conductor temperature | Ambient or operating condition | Affects allowable rise |

| Final temperature limit | Insulation withstand capability | Defines safety margin |

| Installation condition | Buried, tray, conduit | Impacts heat dissipation |

Accounting for these parameters ensures that how to calculate earth cable size results in safe and compliant conductor selection.

Dive deeper into instrument earthing iec standard

Standard Formula Used in Calculations

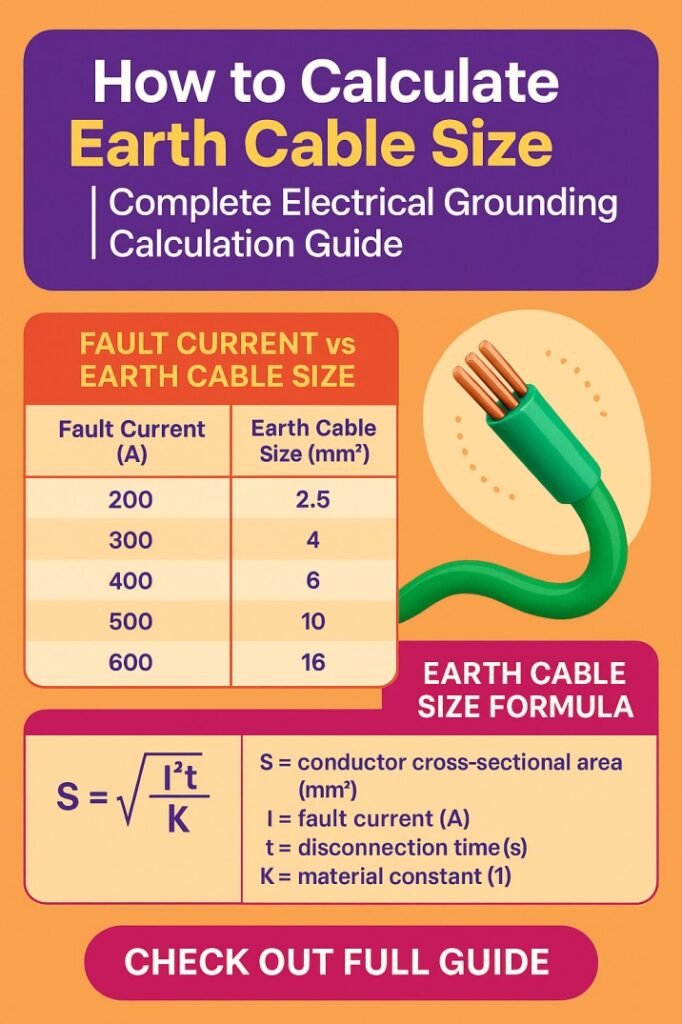

The most widely used thermal equation comes from international wiring standards and is central to understanding how to calculate earth cable size. It is expressed as:

S = √(I² × t) / k

Where S represents conductor cross sectional area, I is fault current, t is fault duration, and k is a material constant derived from resistivity and temperature characteristics.

Typical k values are provided below for reference.

| Material | Insulation Type | k Value |

|---|---|---|

| Copper | PVC | 115 |

| Copper | XLPE | 143 |

| Aluminum | PVC | 76 |

| Aluminum | XLPE | 94 |

Using the proper constant is essential when applying how to calculate earth cable size because incorrect values produce inaccurate conductor ratings.

Know more about IEC Standard for Earthing System

Step by Step Calculation Example

Applying how to calculate earth cable size becomes clearer through a practical example. Consider a system where the fault current is 5 kA and the protection clears the fault in 0.4 seconds. Assume a copper conductor with PVC insulation.

First compute the product of current squared and time:

I² × t = 5000² × 0.4

I² × t = 25,000,000 × 0.4

I² × t = 10,000,000

Next take the square root:

√10,000,000 = 3162

Explore details on table 250.122 nec

Divide by the k constant:

S = 3162 / 115

S ≈ 27.5 mm²

From standard cable sizes, the next available rating would be 35 mm². This practical demonstration shows how to calculate earth cable size for real installations while ensuring compliance with standardized conductor increments.

Comparison With Simplified Rule Based Sizing

In some low voltage systems, simplified ratios between phase conductors and protective conductors are used instead of thermal equations. However, professionals still verify results using how to calculate earth cable size through analytical methods, especially where fault levels are high.

Know all the basics about earth conductor size calculation

A comparison of typical rule based sizing is shown below.

| Phase Conductor Size | Minimum Earth Conductor |

|---|---|

| Up to 16 mm² | Same as phase |

| 16–35 mm² | 16 mm² |

| Above 35 mm² | Half of phase conductor |

These approximations offer quick guidance, yet detailed calculation remains the preferred engineering practice when system data is available.

Installation and Environmental Considerations

Applying how to calculate earth cable size does not end with mathematics. Real world installation factors influence final selection. Conductors exposed to high ambient temperatures or grouped with other cables may require adjustment. Mechanical strength, corrosion resistance, and soil resistivity also affect long term performance.

Find all about substation earthing design

Buried grounding conductors must withstand moisture and chemical exposure, while tray installed conductors must resist vibration and accidental impact. Engineers sometimes increase conductor size beyond calculated values to provide durability and lower impedance paths.

Verification Through Fault Loop Impedance

Another perspective on how to calculate earth cable size involves checking the grounding path impedance. Even if thermal capacity is sufficient, excessive impedance can delay protective device operation. Verification ensures that disconnection times remain within regulatory limits.

Measurements or simulations evaluate whether the selected conductor allows enough fault current flow. This additional validation improves safety and reliability of the earthing system. Find more about iec grounding standards

Documentation and Compliance Practices

Professionals documenting how to calculate earth cable size typically include calculation sheets, assumptions, and design margins. Compliance with local electrical codes and international wiring standards ensures acceptance by inspectors and project stakeholders.

Clear documentation also helps maintenance teams understand system capability during upgrades or modifications. Maintaining records of conductor ratings, fault levels, and protection settings ensures consistent safety management across the facility lifecycle.

Practical Tips for Engineers and Technicians

Experience plays a large role in mastering how to calculate earth cable size effectively. Engineers often adopt practical habits such as confirming breaker clearing curves, validating available fault current data, and considering future load expansion. Selecting corrosion resistant materials and verifying bonding continuity improves grounding reliability.

Know more about European Earthing System TN-S TN-C-S TT Explained: Key Differences, Safety, and Standards

Periodic inspection of grounding connections ensures calculated performance is maintained throughout system operation. Good design combined with ongoing maintenance forms the foundation of a dependable earthing network.

Conclusion

Understanding how to calculate earth cable size is essential for anyone involved in electrical design, installation, or maintenance. Correct sizing protects equipment, reduces hazard risk, and ensures regulatory compliance. By evaluating fault current, clearing time, conductor material, and environmental conditions, engineers create grounding paths capable of handling extreme electrical stress.

Know more about Earth Fault Relay Testing Procedure

This guide demonstrated how to calculate earth cable size through theoretical explanation, formula application, and practical design considerations. Using structured methods instead of assumptions results in safer installations and improved system stability. Mastery of these principles allows professionals to design earthing conductors that perform reliably under both normal and fault conditions while supporting the long term integrity of electrical infrastructure. Get instant results with our online tool earth cable size calculator

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#EarthCableSizeCalculation, #CableSizingGuide, #ElectricalDesign, #GroundingSystem, #PowerEngineering, #ElectricalStandards, #CableSelection, #EarthingDesign, #EngineeringCalculations, #ElectricalSafety