High Voltage Cable Testing Procedure: Step-by-Step Guide for Safe & Accurate HV Cable Testing

High voltage cable testing is a critical aspect of electrical engineering, ensuring the reliability and safety of power transmission systems. Implementing a proper high voltage cable testing procedure helps in detecting insulation faults, reducing downtime, and avoiding catastrophic failures. Whether you are dealing with newly installed cables or maintaining aged systems, following a standardized HV cable testing procedure is essential to achieve accurate results while maintaining safety standards.

Table of Contents

Understanding High Voltage Cable Testing

High voltage cable testing involves assessing the electrical integrity of cables that carry high voltage, usually above 1 kV. The main objective is to identify insulation weaknesses, manufacturing defects, or damages that might have occurred during installation or service. Common testing techniques include insulation resistance measurement, DC high voltage testing, tan delta testing, and partial discharge analysis. Each method provides different insights into the condition of the cable system.

Using a well-structured high voltage cable testing procedure minimizes the risk of equipment damage and ensures compliance with international standards like IEC, IEEE, and ASTM. Testing should always be conducted by trained personnel using calibrated equipment to maintain accuracy and safety.

Discover everything about cable bending radius iec standard

Pre-Test Preparations for HV Cable Testing

Before starting any high voltage cable testing procedure, proper preparation is crucial. Neglecting pre-test steps can lead to inaccurate results or severe accidents. Essential preparations include:

- Visual Inspection: Check for visible damage, insulation cracks, or loose connections.

- System De-energization: Ensure the cable is completely isolated from the power supply.

- Grounding: Properly ground all associated equipment to prevent electric shock.

- Environmental Conditions: Record ambient temperature, humidity, and ensure dry conditions to reduce measurement errors.

- Documentation: Review cable specifications, installation records, and previous test reports.

Proper pre-test preparations set the foundation for a safe and effective high voltage cable testing procedure.

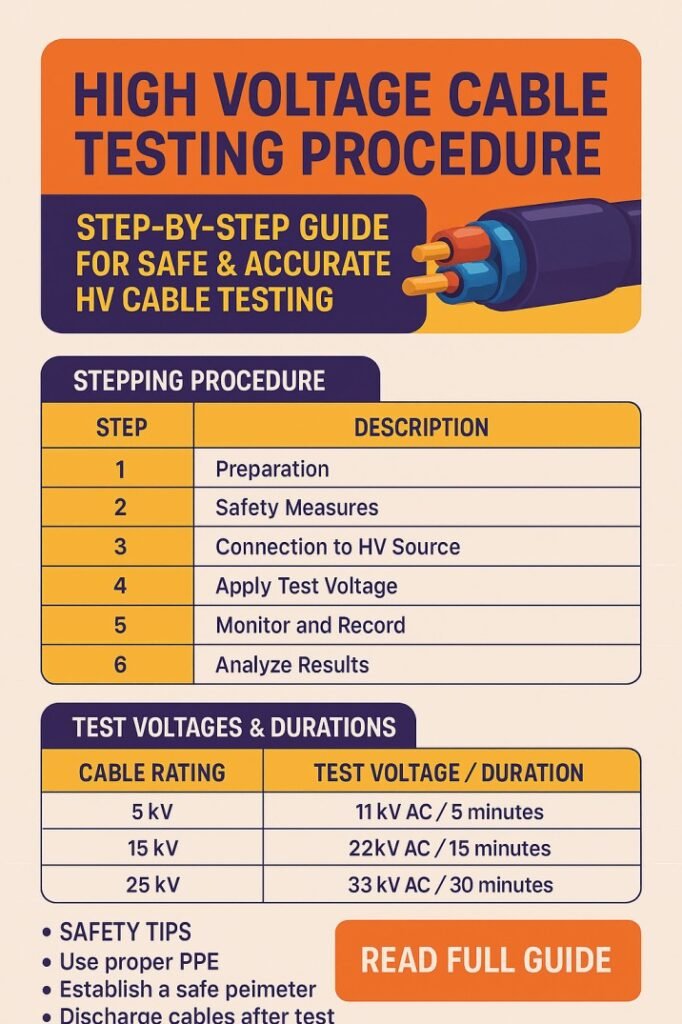

Step-by-Step High Voltage Cable Testing Procedure

The following step-by-step guide explains the high voltage cable testing procedure used in the field:

Step 1: Insulation Resistance Test

The insulation resistance test evaluates the dielectric strength of the cable insulation. A megger or insulation resistance tester is commonly used.

Procedure:

- Disconnect the cable from all equipment.

- Connect the insulation resistance tester to the cable conductors and ground.

- Apply a DC voltage (usually 500V to 5kV depending on cable rating).

- Record the insulation resistance in megaohms (MΩ).

- Compare readings with standard values for the cable type.

Explore details on iec standard for underground cable laying

| Cable Type | Nominal Voltage | Minimum Insulation Resistance |

|---|---|---|

| 11 kV XLPE | 11 kV | 50 MΩ/km |

| 33 kV XLPE | 33 kV | 100 MΩ/km |

| 66 kV XLPE | 66 kV | 200 MΩ/km |

Anomalies or low insulation resistance may indicate moisture ingress, insulation damage, or contamination.

Step 2: High Voltage DC Test (Hipot Test)

The high voltage DC test, or hipot test, applies a voltage higher than the operating level to verify the cable’s insulation capability.

Procedure:

- Ensure proper grounding and safety clearances.

- Gradually apply DC voltage to the cable, following recommended step-up rates.

- Maintain voltage for the specified duration (usually 5-15 minutes).

- Monitor leakage current continuously.

- Gradually reduce voltage before disconnecting the test equipment.

A steady leakage current within permissible limits indicates good insulation. Sudden spikes or breakdowns suggest faults in the cable.

Know more about IEC Standard for MV Cable Testing: Complete Acceptance, Routine & Type Test Guide

Step 3: Tan Delta Testing

Tan delta testing, also known as dissipation factor measurement, detects insulation deterioration and moisture content. It is particularly useful for high voltage XLPE and PILC cables.

Procedure:

- Connect the tan delta testing instrument according to manufacturer instructions.

- Apply a low-frequency AC voltage (typically 0.1 Hz to 0.5 Hz).

- Measure the tan delta value and capacitance at different voltage levels.

- Compare results with baseline or standard values.

Higher tan delta values indicate insulation aging, contamination, or water treeing in XLPE cables.

Step 4: Partial Discharge Testing

Partial discharge (PD) testing identifies localized insulation defects that could lead to failure over time. PD testing is crucial for high-voltage cables operating above 33 kV.

Procedure:

- Connect PD sensors or couplers to the cable terminations.

- Apply test voltage gradually while monitoring discharge pulses.

- Record PD magnitude and phase-resolved patterns.

- Analyze results to locate potential weak spots or voids in the insulation.

Partial discharge measurements allow predictive maintenance, extending cable life and preventing unexpected outages.

Access our powerful online calculator now Electrical Diversity Calculator for accurate Load Estimation and efficient electrical Design.

Step 5: Sheath Testing

Sheath testing ensures that the cable’s metallic sheath is intact and not compromised by moisture or mechanical damage.

Procedure:

- Disconnect cable sheath from the system and ground it temporarily.

- Apply DC or AC voltage between the sheath and ground.

- Measure leakage current and insulation resistance.

- Document any abnormal readings for corrective actions.

A continuous low leakage current confirms a healthy cable sheath, which is vital for overall cable reliability.

Safety Considerations During HV Cable Testing

High voltage cable testing can be dangerous if proper precautions are not taken. Observing safety protocols is mandatory:

- Always maintain a safe distance from energized equipment.

- Use insulated gloves, mats, and barriers to prevent accidental contact.

- Confirm all personnel are aware of testing schedules.

- Avoid testing during adverse weather conditions or high humidity.

- Ensure emergency shutdown procedures are accessible and tested.

Adhering to safety standards protects personnel and ensures the high voltage cable testing procedure is executed reliably.

Know more about VLF Testing vs Hipot: Best Guide on Key Differences and Applications

Recording and Analyzing Test Data

After completing the tests, accurate documentation is necessary for future reference and maintenance planning.

- Record all measured values in a structured logbook.

- Compare results with manufacturer specifications and previous test data.

- Identify trends such as decreasing insulation resistance or increasing tan delta values.

- Use data to plan corrective measures or replacement schedules.

Consistent record-keeping enhances predictive maintenance and improves the overall reliability of power distribution networks.

Benefits of Following a Structured HV Cable Testing Procedure

Adhering to a standardized high voltage cable testing procedure provides several advantages:

- Early detection of cable defects prevents costly downtime.

- Ensures compliance with safety and regulatory standards.

- Extends cable lifespan through timely maintenance.

- Reduces risk of electrical accidents and fires.

- Improves overall network reliability and efficiency.

Investing time in a structured testing approach saves money and enhances operational safety.

Find all about High Voltage Cable Testing Standards: Complete Guide for Engineers

Recommended Equipment for High Voltage Cable Testing

Having the right tools simplifies the high voltage cable testing procedure and improves accuracy. Essential equipment includes:

| Equipment | Purpose |

|---|---|

| Insulation Resistance Tester (Megger) | Measures cable insulation resistance |

| High Voltage DC Tester (Hipot) | Verifies dielectric strength |

| Tan Delta Meter | Assesses insulation degradation |

| Partial Discharge Detector | Detects localized insulation faults |

| Earth Resistance Tester | Ensures proper grounding |

| Clamp Meters and Multimeters | Auxiliary measurements |

Using calibrated and certified instruments ensures test results are reliable and repeatable.

Conclusion

Following a well-structured high voltage cable testing procedure is vital for maintaining electrical system safety and reliability. From insulation resistance measurement to partial discharge testing, each step provides critical insights into cable health. Proper pre-test preparation, adherence to safety protocols, and accurate recording of results ensure that testing is effective and safe.

Explore all about vlf testing procedure

Regular implementation of this procedure allows for early detection of potential failures, minimizing downtime and extending cable life. By integrating modern testing techniques and predictive maintenance practices, utilities and industrial facilities can optimize their high voltage network performance with confidence.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#HighVoltageCableTesting #CableTestingProcedure #HVTesting #ElectricalTesting #PowerCableTesting #VLFTesting #HipotTest #CableDiagnostics #ElectricalMaintenance #SubstationTesting