Difference Between RTD and Thermocouple: Best Guide

RTDs (Resistance Temperature Detectors) and Thermocouples have the same basic function of temperature measurement but there is a significant difference between RTD and thermocouple when we study the design, precision, and applications. There are several industrial and scientific applications for temperature sensors, including RTD (Resistance Temperature Detector) and thermocouples.

We will examine the difference between RTD and thermocouple in this in-depth comparison, concentrating on both well-known and frequently under-discussed technical aspects.

Table of Contents

Difference Between RTD and Thermocouple

Two different types of temperature sensors, RTDs and thermocouples, are frequently used in a wide range of industrial and scientific applications. One key difference between RTD and thermocouple lies in their operating principles. The linear relationship between temperature and electrical resistance is the basis for RTDs or resistance temperature detectors.

These sensors are frequently made of platinum wire wound around a ceramic or glass core, which makes them extremely accurate and stable over a broad temperature range.

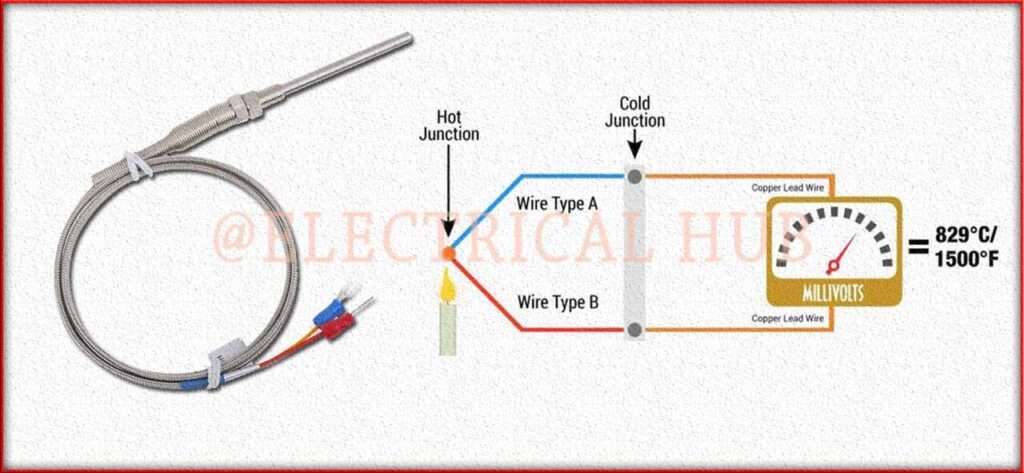

The voltage produced at the junction of two different metals in thermocouples, in contrast, is based on the Seebeck effect, where the voltage is proportional to the temperature difference. One of the key distinctions between RTDs and thermocouples is the inherent difference in their operating principles.

Operating Principle

RTD: RTDs work on the premise that a material’s electrical resistance varies with temperature. As the sensing element, they typically use pure platinum wire wound around a ceramic or glass core. RTDs are extremely accurate and stable due to the linear temperature increase in platinum resistance.

Thermocouple: Thermocouples use the Seebeck effect, which involves joining two different metals at one end to produce a voltage that is proportional to the difference in temperature between the hot junction and the cool junction. With temperature, the voltage output fluctuates nonlinearly.

Range of temperatures

RTD: RTDs have a limited operating temperature range, typically between -200°C and 600°C. For applications requiring extremely high temperatures, they are not ideal.

Thermocouple: Thermocouples can withstand temperatures as low as -200°C and as high as 2300°C. Both low-temperature and high-temperature applications are well suited to them.

Accuracy

RTD: RTDs are renowned for being extremely accurate and stable. They offer accurate temperature readings up to 0.1 degrees Celsius.

Thermocouple: Thermocouples typically have accuracy ranges between 1°C and 5°C, making them less accurate than RTDs.

Response Time

RTD: Due to its greater mass and thermal inertia, RTDs respond more slowly than thermocouples.

Thermocouple: Because of its smaller size and lower thermal mass, thermocouples react to temperature changes more quickly.

Linearity

RTD: Because of the RTDs’ linear and consistent resistance-temperature relationship, temperature correction and calibration are simple.

Thermocouple: Accurate temperature readings from thermocouples require specialized tables or linearization methods due to their non-linear voltage-temperature connection.

Self-Heating

RTD: RTDs operate with the least amount of self-heating possible, minimizing interference with the temperature being measured.

Thermocouple: Thermocouples are susceptible to self-heating which can significantly impair their accuracy, particularly in high-temperature applications.

Sensitivity to the Temperature Spectrum

RTD: Within a specific temperature range, RTDs are very accurate thermometers that are sensitive to changes.

Thermocouple: Thermocouples are better suited for applications that need the measurement of a broad range of temperatures.

Applications

RTD: RTDs are frequently employed in systems like HVAC units, laboratory equipment, and pharmaceutical manufacture where accuracy and stability are essential. They are also preferred in the food business for their ability to precisely manage temperature.

Thermocouple: Thermocouples are favored in fields where high temperatures are present, such as metallurgy, aerospace, and power generation. They are also utilized in furnaces, exhaust gas monitoring, and ovens.

Finally, the difference between RTD and Thermocouple goes beyond their fundamental modes of operation and temperature range. Thermocouples thrive in high-temperature situations and offer a faster response time while RTDs are more accurate and stable over a narrower temperature range.

The precise needs of the application and the described, frequently under-discussed technical variations must be taken into account when choosing the appropriate temperature sensor.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts