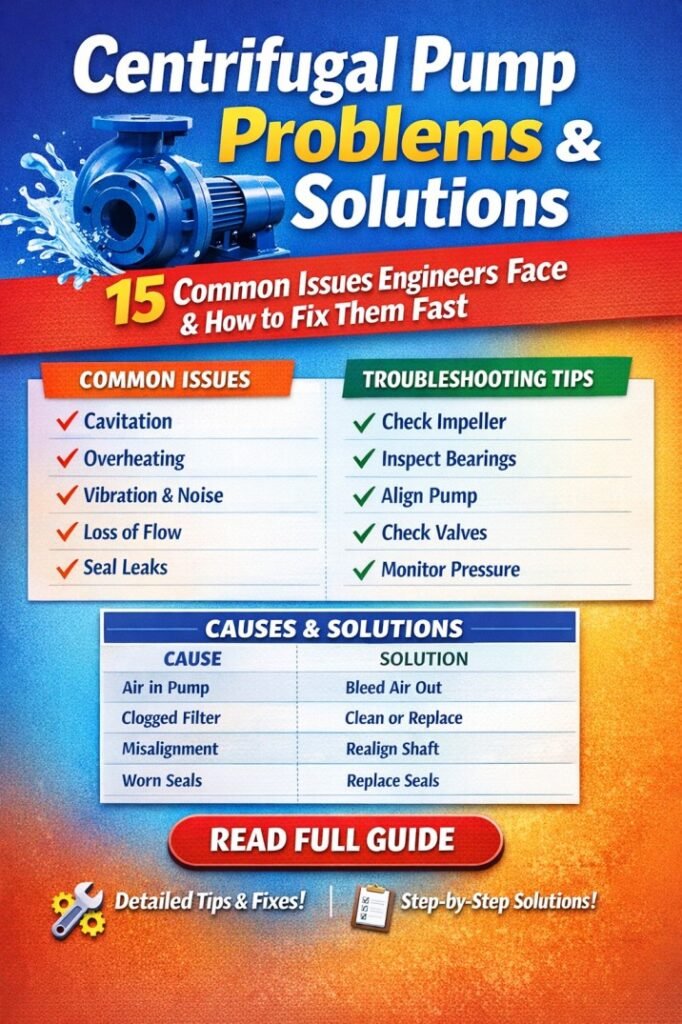

Centrifugal Pump Problems and Solutions – 15 Common Issues Engineers Face & How to Fix Them Fast

Centrifugal pumps are among the most widely used machines in industrial plants, water supply systems, HVAC installations, and process industries. Despite their simple construction, engineers frequently encounter operational issues that affect efficiency, reliability, and service life.

Understanding centrifugal pump problems and solutions is essential for maintenance engineers, plant operators, and design professionals who want to minimize downtime and avoid costly repairs. This guide explains the most common problems faced in centrifugal pumps, their root causes, and practical fixes that can be implemented quickly on site.

Table of Contents

Why Centrifugal Pump Problems Occur

Most centrifugal pump failures are not sudden. They develop gradually due to poor installation, incorrect operation, inadequate maintenance, or system design flaws. Factors such as cavitation, seal failure, vibration, and low flow conditions are often symptoms rather than the actual cause. A structured approach to centrifugal pump problems and solutions helps engineers identify the issue early and restore normal operation efficiently.

1. Pump Not Delivering Any Flow

A pump running but delivering no liquid is a common field complaint.

Possible causes

- Air trapped in suction line

- Closed discharge or suction valve

- Incorrect pump rotation

- Suction lift too high

Quick solutions

- Prime the pump properly

- Open all isolation valves fully

- Verify motor rotation direction

- Reduce suction lift or improve suction piping

Know more about What Are Different Types of Overcurrent Relays? Best Guide

2. Low Flow or Reduced Capacity

When a pump delivers less flow than expected, system performance suffers.

Possible causes

- Partially blocked impeller

- Worn impeller or wear rings

- Air leakage in suction line

- Operating far from best efficiency point

Quick solutions

- Clean the impeller and casing

- Replace worn components

- Tighten suction connections

- Match pump operation with system curve

3. Insufficient Discharge Pressure

Low discharge pressure is often confused with low flow but has different root causes.

Possible causes

- Excessive internal clearances

- Incorrect impeller diameter

- High system resistance

- Pump speed lower than design

Quick solutions

- Restore internal clearances

- Use correct impeller size

- Review system head losses

- Check motor speed and frequency

Know more about What Are the Applications of Overcurrent Relays in Power Systems?

4. Cavitation in Centrifugal Pumps

Cavitation is one of the most damaging centrifugal pump problems engineers face.

Symptoms

- Noise like gravel

- Vibration

- Pitting on impeller surfaces

Possible causes

- Low net positive suction head available

- High fluid temperature

- Blocked suction strainer

Quick solutions

- Increase suction head

- Reduce fluid temperature

- Clean or replace suction strainers

5. Excessive Vibration

High vibration shortens bearing and seal life.

Possible causes

- Misalignment

- Unbalanced impeller

- Pipe strain

- Foundation issues

Quick solutions

- Perform laser alignment

- Balance the impeller dynamically

- Support piping properly

- Strengthen or repair foundation

Know more about Thermal Overload Relay: Working Principle, Types and Important Settings Calculation

6. Pump Overheating

Overheating indicates inefficient operation.

Possible causes

- Running at very low flow

- Bearing lubrication failure

- Excessive internal friction

Quick solutions

- Avoid dead head operation

- Use correct lubricant and intervals

- Replace damaged bearings

7. Seal Leakage

Mechanical seal leakage is a frequent maintenance concern.

Possible causes

- Dry running

- Incorrect seal installation

- Abrasive particles in fluid

Quick solutions

- Ensure proper priming

- Reinstall seal as per manufacturer guidance

- Improve filtration or flushing arrangement

8. Bearing Failure

Bearings are critical to pump reliability.

Possible causes

- Poor lubrication

- Misalignment

- Excessive axial or radial load

Quick solutions

- Use recommended grease or oil

- Correct alignment issues

- Verify thrust balancing

Know more about Motor Overload Protection Chart: Important Concepts

9. Noisy Pump Operation

Noise is often an early warning sign.

Possible causes

- Cavitation

- Bearing wear

- Hydraulic instability

Quick solutions

- Address suction conditions

- Replace worn bearings

- Operate near best efficiency point

10. High Power Consumption

A sudden rise in power draw increases operating cost.

Possible causes

- Higher fluid density or viscosity

- Impeller damage

- Mechanical rubbing

Quick solutions

- Verify fluid properties

- Repair or replace impeller

- Check clearances and alignment

11. Pump Loses Prime Frequently

Loss of prime disrupts continuous operation.

Possible causes

- Air leaks in suction piping

- Faulty foot valve

- Improper priming system

Quick solutions

- Seal all suction joints

- Replace foot valve

- Upgrade priming arrangement

12. Short Seal or Bearing Life

Repeated failures indicate deeper issues.

Possible causes

- Excessive vibration

- Operation outside design range

- Poor installation practices

Quick solutions

- Reduce vibration sources

- Operate within design limits

- Follow proper installation standards

Know more about Difference Between Star Delta and DOL Starter: A Comprehensive Guide

13. Corrosion and Erosion Damage

Material damage reduces pump life.

Possible causes

- Aggressive chemicals

- High solid content

- Incorrect material selection

Quick solutions

- Use corrosion resistant materials

- Reduce solids concentration

- Review material compatibility

14. Pump Trips on Overload

Unexpected trips affect production continuity.

Possible causes

- Motor undersized

- High discharge pressure

- Mechanical binding

Quick solutions

- Check motor sizing

- Reduce system head

- Inspect for mechanical issues

15. Frequent Maintenance Intervals

High maintenance demand increases lifecycle cost.

Possible causes

- Poor pump selection

- Incorrect operating point

- Inadequate preventive maintenance

Quick solutions

- Select pump based on system analysis

- Optimize operating range

- Implement condition-based monitoring

Know more about How does the star delta starter reduce starting current? Important Concepts

Common Centrifugal Pump Problems and Solutions at a Glance

| Problem | Primary Cause | Fast Fix |

|---|---|---|

| No flow | Air lock | Proper priming |

| Low capacity | Worn impeller | Replace parts |

| Cavitation | Low NPSH | Improve suction |

| Vibration | Misalignment | Realign pump |

| Seal leakage | Dry running | Ensure priming |

| Overheating | Low flow | Increase flow |

| Bearing failure | Poor lubrication | Correct lubrication |

| High power draw | Impeller damage | Repair impeller |

Preventive Approach to Reduce Pump Failures

A proactive strategy significantly reduces centrifugal pump problems and solutions related downtime.

- Monitor vibration and temperature regularly

- Maintain proper alignment and lubrication

- Keep suction piping short and straight

- Operate pumps close to best efficiency point

- Train operators on correct startup and shutdown

Final Thoughts

Centrifugal pumps are reliable machines when operated and maintained correctly. Most failures are predictable and preventable if engineers understand the underlying causes and apply proven corrective actions. By applying the centrifugal pump problems and solutions discussed in this guide, engineers can improve system reliability, extend equipment life, and reduce maintenance costs.

Use our online tool Generator Sizing Calculator for Pumps

A disciplined approach to troubleshooting, combined with preventive maintenance, ensures centrifugal pumps perform efficiently under real-world operating conditions.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#CentrifugalPumpProblems, #PumpTroubleshooting, #CentrifugalPumpSolutions, #IndustrialPumps, #PumpMaintenance, #MechanicalEngineering, #FluidHandling, #PumpFailure, #EngineeringTips, #ProcessEngineering