Cable Size for Motor Calculator: A Comprehensive Guide

Choosing the right cable size for a motor is crucial for ensuring efficient performance and preventing risks like overheating or power loss. This guide explores how a cable size for motor calculator simplifies the process of selecting the correct cable based on the motor’s electrical load and offers tips on voltage drop calculations, essential tables, and best practices in cable selection.

Why Use a Cable Size for Motor Calculator?

A cable size for motor calculator is an essential tool for electricians, engineers, and DIY enthusiasts. It ensures the selected cable meets the motor’s power requirements without compromising safety. Factors like the motor’s rated current, supply voltage, phase (single or three-phase), and installation environment significantly influence the appropriate cable size.

Key Factors in Cable Selection for Motors

To understand cable selection for motor applications, you need to consider several key factors:

Rated Power of the Motor: Cable size largely depends on the motor’s power, typically measured in kilowatts (kW) or horsepower (HP).

Current Capacity (Amperes): The current drawn by the motor determines the minimum cable cross-section area to avoid overheating.

Voltage Drop: Minimizing voltage drop is essential to maintain motor efficiency, especially for long cable runs.

Temperature Rating of Cable Insulation: Cable insulation materials have different heat tolerances, influencing the cable’s current-carrying capacity.

Installation Environment: Factors like cable length, ambient temperature, and whether it’s installed underground or in open air can impact cable choice.

Note: Use our online electrical load calculator for electrical load calculation here. You can also use voltage drop calculator for voltage drop calculation for cable selection in any single and three phase circuit here. Further explore our online electrical calculators to design your electrical systems in an efficient way.

Step-by-Step Guide on How to Use a Cable Size for Motor Calculator

Here’s a step-by-step guide to help you effectively use a cable size for motor calculator.

Step 1: Gather Necessary Information

Before using a calculator, you’ll need the following details:

- Motor power rating (in kW or HP)

- Supply voltage (in volts)

- Motor efficiency and power factor (typically given by the manufacturer)

- Cable length (distance from the power source to the motor)

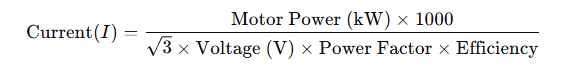

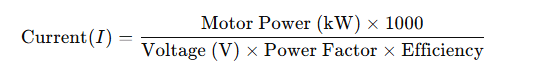

Step 2: Calculate the Current Requirement

Using the formula for motor current calculation, you can estimate the required current. Here’s the formula:

For a three-phase motor:

For a single-phase motor:

Step 3: Use the Cable Size for Motor Calculator

Once you’ve determined the required current, input this value into the cable size calculator. The calculator will consider factors like voltage drop, insulation temperature rating, and installation conditions to suggest a suitable cable size.

Cable Size for Motor Chart

Using a cable size chart alongside your calculator results is a good practice to verify your selection. Below is a simplified table for common motor ratings:

| Motor Power (kW) | Rated Current (A) | Cable Size (sq mm) – Copper | Cable Size (sq mm) – Aluminum |

|---|---|---|---|

| 0.75 | 1.7 | 1.5 | 2.5 |

| 1.5 | 3.4 | 2.5 | 4 |

| 2.2 | 5 | 4 | 6 |

| 5.5 | 11 | 6 | 10 |

| 11 | 22 | 10 | 16 |

| 15 | 30 | 16 | 25 |

| 22 | 44 | 25 | 35 |

Note: Always cross-check these values with a cable size for motor calculator, as additional factors (e.g., installation method, ambient temperature) can alter cable sizing needs.

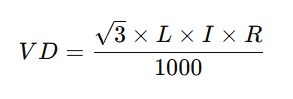

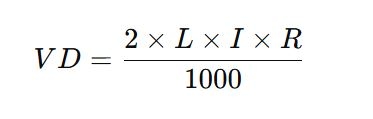

Calculating Voltage Drop

Minimizing voltage drop is essential for efficient motor operation. Excessive voltage drop can lead to power losses and reduced motor lifespan. Here’s a basic formula:

For accurate results, a voltage drop calculator can be beneficial. It takes into account the cable type, material (copper or aluminum), and installation environment to provide a more reliable estimate of voltage drop.

Electrical Load Calculation for Motor Cable Selection

When selecting a motor cable, electrical load calculation helps assess the total demand on the cable, avoiding overload in motor. A comprehensive electrical load calculator assists in balancing multiple devices connected to a single circuit, improving overall system efficiency. An electrical load calculation table like the one below can serve as a reference:

| Device | Power Rating (W) | Quantity | Total Power (W) |

|---|---|---|---|

| Motor | 1500 | 1 | 1500 |

| Lighting | 60 | 10 | 600 |

| Additional Loads | – | – | – |

| Total Load (W) | 2100 |

This calculation is crucial for multi-motor systems, where each motor contributes to the overall load.

Best Practices for Cable Selection for Motor

To select the right cable size, keep these practices in mind:

- Allow for Future Expansion: When possible, opt for a slightly larger cable size to account for future expansions.

- Consult Manufacturer Recommendations: Manufacturers often provide motor-specific cable recommendations.

- Check Regulatory Standards: Standards like IEC and NEC offer guidelines for safe motor cabling.

- Use a Voltage Drop Calculator: Verify voltage drop to maintain efficiency, especially for long-distance installations.

Common Mistakes in Motor Cable Sizing

Avoid these pitfalls for safe and efficient cable selection:

- Ignoring Voltage Drop: Ignoring voltage drop can lead to motor underperformance.

- Choosing Undersized Cables: Undersized cables can cause overheating and energy losses.

- Overlooking Environmental Factors: Temperature, moisture, and installation method can impact the cable’s current-carrying capacity.

- Skipping Load Calculation: Estimating the motor’s total load helps in selecting an adequately rated cable.

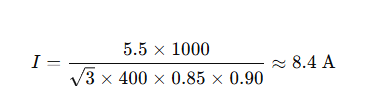

Example Calculation Using a Cable Size for Motor Calculator

For a three-phase 5.5 kW motor with a supply voltage of 400V, efficiency of 90%, and power factor of 0.85:

Calculate Current:

Input into Calculator: Input the current (8.4 A) and other details like cable length into the cable size for motor calculator.

Determine Cable Size: The calculator suggests a cable size based on the load and installation factors.

This example highlights how a cable size calculator simplifies the process and ensures accurate results.

Conclusion

Using a cable size for motor calculator is essential for accurate and safe cable selection, especially in motor applications where current and voltage requirements vary significantly. By combining the calculator with load calculation tables and a voltage drop calculator, you can ensure efficient motor operation, reduced energy losses, and longer cable lifespan. Always follow industry best practices, consult the relevant standards, and consider environmental factors when making your selection.

With these guidelines, you’ll be equipped to select the right cable size confidently for any motor application, enhancing safety and efficiency across your electrical installations.

Follow us on LinkedIn, “Electrical Insights,” to get the latest updates on electrical engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

#CableSizeCalculator, #MotorCableSizing, #ElectricalCalculations, #MotorCableSelection, #IndustrialElectricity, #ElectricalEngineering, #CableSizingGuide, #MotorCalculator, #ElectricMotorCable, #CableSizingTips, #EngineeringGuide, #ElectricalTools, #MotorEfficiency, #PowerCalculations, #ElectricSystems