Busbar Size Chart in mm: Electrical Design Guide for Accurate Busbar Selection

Designing a reliable power distribution system requires careful attention to conductor sizing. Engineers often rely on a busbar size chart in mm to match current demand with proper copper or aluminium bar dimensions. When sizing is done correctly, heat rise remains controlled, voltage drop stays low, and mechanical strength is adequate for fault conditions. This guide explains how to interpret ratings, understand selection criteria, and apply a practical busbar size chart in mm during real project work.

Table of Contents

Understanding Busbar Sizing Fundamentals

Electrical Busbars are solid conductors used in switchgear panels, motor control centers, and distribution boards. Unlike cables, their current carrying capability depends heavily on surface area, spacing, and cooling conditions. A well-prepared busbar size chart in mm helps engineers estimate cross sectional area and ampacity before performing final thermal calculations.

Find out more about iec 61439 busbar clearance

Key factors affecting selection include conductivity, installation environment, permissible temperature rise, and fault withstand capability. Copper busbars offer lower resistivity and better thermal performance, while aluminium busbars reduce weight and cost but require larger sections. Using a consistent busbar size chart in mm ensures compatibility with standard fabrication practices and enclosure layouts.

Importance of Dimensional Charts in Engineering Practice

A dimensional reference chart supports accurate panel design and prevents oversizing or undersizing. When referencing a busbar size chart in mm, engineers can quickly map load current to width and thickness combinations. This speeds procurement planning and helps maintain uniform spacing for insulation clearance.

Dimensional charts also support coordination with protective devices. Circuit breaker interrupt ratings, short circuit levels, and earthing arrangements depend on conductor size. Reviewing the busbar size chart in mm alongside fault calculations helps confirm that bars can survive mechanical forces during high current events. Get complete information about iec standard for busbar sizing

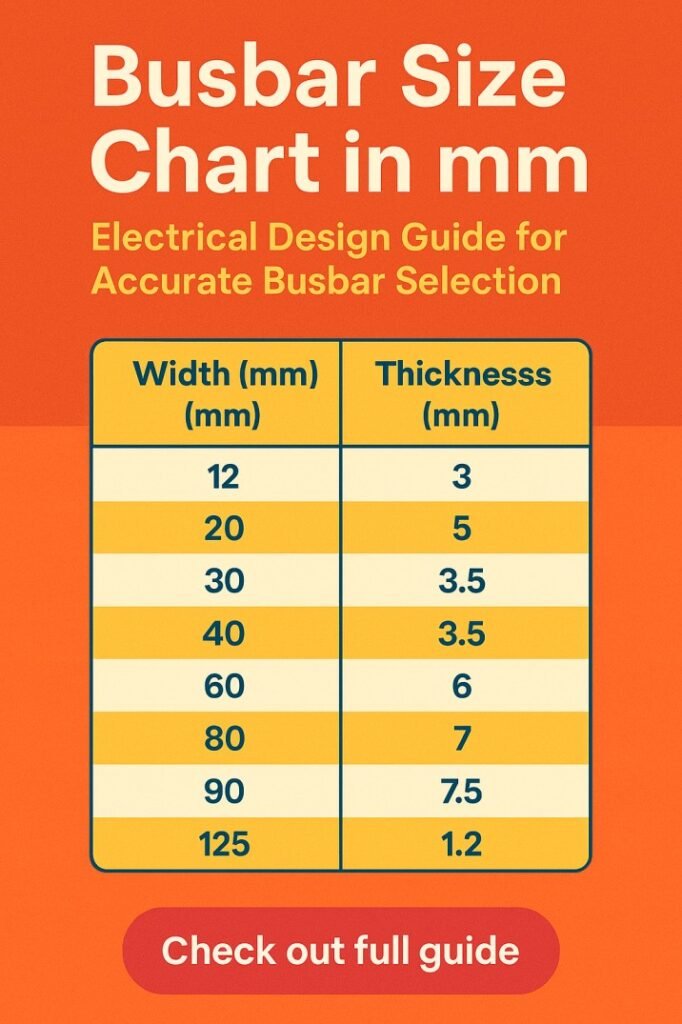

Typical Copper Busbar Size Chart

The following table presents commonly used copper sections with approximate current ratings under natural air cooling. Values are indicative and should be validated for enclosure conditions, ambient temperature, and grouping effects.

Copper Busbar Size Chart in mm

| Width (mm) | Thickness (mm) | Cross Section (sq mm) | Approx Current Rating (A) |

|---|---|---|---|

| 20 | 3 | 60 | 140 |

| 25 | 3 | 75 | 170 |

| 25 | 5 | 125 | 230 |

| 30 | 5 | 150 | 270 |

| 40 | 5 | 200 | 350 |

| 40 | 8 | 320 | 470 |

| 50 | 5 | 250 | 420 |

| 50 | 10 | 500 | 700 |

| 60 | 10 | 600 | 820 |

| 80 | 10 | 800 | 1080 |

| 100 | 10 | 1000 | 1350 |

| 120 | 10 | 1200 | 1600 |

These ratings provide a starting point when working with a busbar size chart in mm for distribution boards and switchgear assemblies. Read in detail about iec 61439 busbar calculation

Aluminium Busbar Reference Values

Aluminium requires larger dimensions to carry the same current due to higher resistivity. Still, it remains popular in utility and industrial installations. Designers comparing materials often consult a parallel busbar size chart in mm to verify equivalence.

Aluminium Busbar Size Chart in mm

| Width (mm) | Thickness (mm) | Cross Section (sq mm) | Approx Current Rating (A) |

|---|---|---|---|

| 25 | 5 | 125 | 160 |

| 30 | 5 | 150 | 190 |

| 40 | 5 | 200 | 250 |

| 50 | 5 | 250 | 300 |

| 50 | 8 | 400 | 420 |

| 60 | 10 | 600 | 600 |

| 80 | 10 | 800 | 780 |

| 100 | 10 | 1000 | 950 |

| 120 | 10 | 1200 | 1100 |

These values illustrate how aluminium dimensions grow compared with copper when reading a busbar size chart in mm.

Know more about IEC Standard for Busbar Clearance

Factors That Influence Final Selection

Using tabulated data alone is not enough. Engineering judgement must refine the initial pick obtained from a busbar size chart in mm. Ambient temperature above standard assumptions reduces ampacity. Enclosures with limited airflow may require derating.

Spacing between phases and proximity to enclosure walls affects heat dissipation. Surface finish and plating influence resistance and corrosion protection. When working from a busbar size chart in mm, consider insulation sleeves, mounting hardware, and support structures that may alter effective cooling.

Mechanical strength is equally critical. During short circuit conditions, electromagnetic forces act on parallel conductors. Bars must withstand bending stresses without deformation. Verifying mechanical limits after consulting a busbar size chart in mm ensures reliability under fault duty. Find out more about contact resistance test acceptable value for busbar

Sample Selection Approach

A structured process improves accuracy and consistency. Engineers often follow a sequence when applying a busbar size chart in mm in design calculations.

Stepwise Considerations

| Step | Design Action | Purpose |

|---|---|---|

| 1 | Determine full load current | Establish base requirement |

| 2 | Apply diversity or growth factor | Allow future expansion |

| 3 | Choose preliminary size from chart | Use busbar size chart in mm |

| 4 | Check temperature rise | Confirm thermal suitability |

| 5 | Verify short circuit withstand | Ensure mechanical integrity |

| 6 | Confirm clearances | Maintain insulation safety |

| 7 | Finalize material specification | Document copper or aluminium |

Following this workflow ensures the chosen dimensions align with practical installation constraints and performance targets.

Find out more about Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

Installation and Layout Considerations

Correct sizing must be paired with proper installation. Smooth edges, correct torque on bolted joints, and adequate support spacing improve electrical contact and mechanical stability. Engineers referencing a busbar size chart in mm also review insulation coordination, creepage distance, and phase identification.

Orientation matters as well. Vertical mounting may enhance convection cooling, while horizontal stacking can limit heat escape. Parallel bar arrangements may be adopted when a single section from the busbar size chart in mm cannot meet the required rating. Equal spacing and symmetrical layout help share current evenly. Find out more about High Impedance Busbar Protection Explained with Example Calculations

Maintenance and Inspection Practices

Once installed, routine inspection preserves performance. Thermal scanning reveals hotspots caused by loose joints or contamination. Periodic cleaning prevents dust buildup that impairs cooling. Maintenance teams frequently compare installed dimensions against documentation derived from the busbar size chart in mm to confirm no unauthorized modifications occurred.

Corrosion protection should not be overlooked. Tin plating or suitable coatings reduce oxidation, particularly in humid environments. When systems are upgraded, revisiting the busbar size chart in mm ensures additional loads do not exceed original design margins. Find out more about Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

Final Thoughts

Accurate conductor selection underpins every dependable power distribution scheme. Dimensional tables, thermal assessment, and mechanical evaluation combine to deliver safe results. By consistently applying a validated busbar size chart in mm, designers maintain balance between efficiency, cost control, and operational safety.

Practical awareness of material behavior, enclosure conditions, and installation detail strengthens decisions further. A disciplined approach grounded in technical reference data ultimately ensures that busbars perform as expected throughout their service life.

Find all about Busbar Bending Calculation

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#BusbarSizeChart, #BusbarDesign, #ElectricalEngineering, #PowerDistribution, #CopperBusbar, #SwitchgearDesign, #ElectricalCalculations, #BusbarSizing, #EngineeringReference, #ElectricalStandards