Busbar Insulator Size Chart – Standard Dimensions, Ratings & Selection Guide for Engineers

Designing and maintaining reliable power distribution systems requires attention to details that are often overlooked during planning. One such detail is selecting the right insulation support for copper or aluminum conductors. Engineers frequently rely on a busbar insulator size chart to determine suitable dimensions, voltage ratings, and mechanical strength before installation. Choosing correctly affects electrical clearance, heat dissipation, and structural stability in switchboards, panels, and substations.

Table of Contents

This article explains how to read a busbar insulator size chart, understand standard dimensions, and apply practical selection methods in real engineering situations. The discussion covers typical ratings, material considerations, and working examples so that professionals can make confident decisions in the field.

Understanding the Purpose of Busbar Insulators

Busbars carry large currents within switchgear assemblies and distribution boards. They must remain firmly supported and electrically isolated from grounded metal enclosures. Insulators provide this mechanical and dielectric separation.

Find out more about contact resistance test acceptable value for busbar

A busbar insulator size chart helps engineers compare available models by height, diameter, creepage distance, and load capability. Instead of estimating dimensions manually, this reference simplifies specification during procurement and design stages.

These components are commonly manufactured from materials such as epoxy resin, polyester, porcelain, and composite polymers. Each material offers different resistance to heat, moisture, and contamination. The chosen insulator must align with voltage class, environmental conditions, and mounting configuration.

Key Parameters Included in a Busbar Insulator Size Chart

Interpreting a busbar insulator size chart begins with understanding the parameters listed in manufacturer data sheets. Although formatting varies slightly, most charts contain similar fields that guide technical selection.

Mechanical Dimensions

Height and diameter determine spacing between conductors and grounded structures. These dimensions directly influence clearance distances inside compact panels.

Voltage Rating

Rated voltage indicates the maximum system voltage the insulator can withstand under normal operating conditions without breakdown.

Know more about IEC Standard for Busbar Clearance

Creepage Distance

Creepage distance measures the path along the insulator surface between conductive parts. Higher contamination levels require longer creepage distances to prevent tracking.

Cantilever Strength

This parameter reflects the mechanical load capacity when busbars exert bending forces on supports.

Mounting Thread Size

Thread size ensures compatibility with panel hardware and simplifies installation planning.

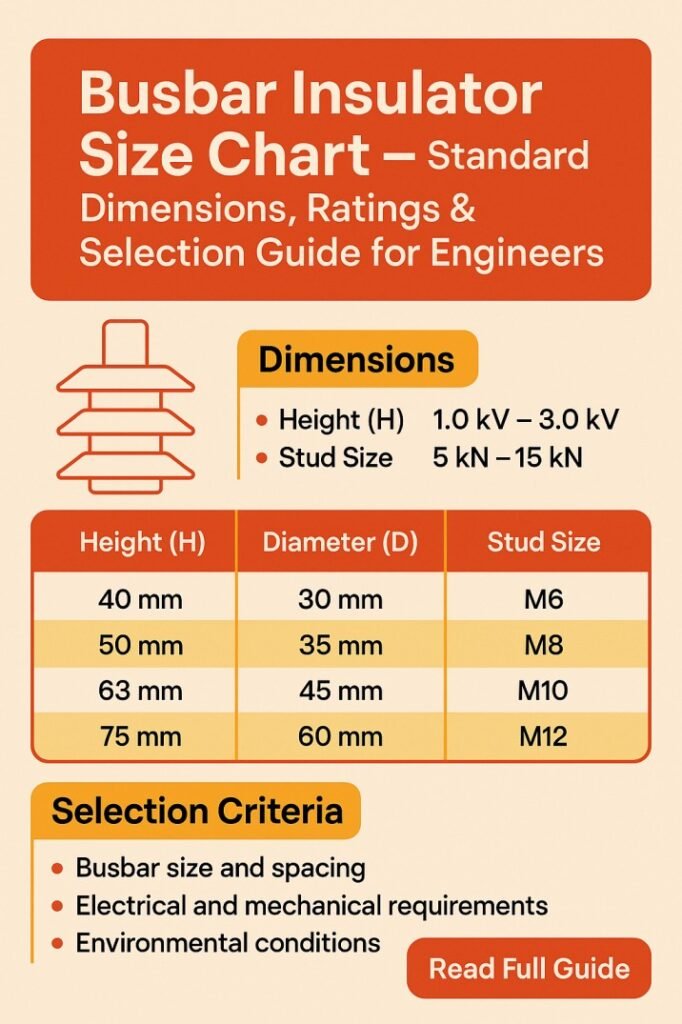

Typical Busbar Insulator Size Chart for Reference

The table below presents representative values often encountered in low and medium voltage assemblies. Exact values vary by manufacturer, but this layout demonstrates how engineers interpret a busbar insulator size chart during design.

| Insulator Height (mm) | Diameter (mm) | Rated Voltage (kV) | Creepage Distance (mm) | Cantilever Strength (kN) | Stud Size |

|---|---|---|---|---|---|

| 25 | 30 | 1 | 45 | 1.5 | M6 |

| 40 | 35 | 1 | 60 | 2.0 | M6 |

| 50 | 40 | 1.2 | 75 | 2.5 | M8 |

| 60 | 45 | 1.5 | 95 | 3.0 | M8 |

| 75 | 50 | 2 | 120 | 4.0 | M10 |

| 90 | 60 | 3 | 150 | 5.0 | M10 |

| 120 | 70 | 5 | 200 | 7.0 | M12 |

When using a busbar insulator size chart like this, engineers normally compare clearance requirements, expected mechanical stress, and voltage level before narrowing down suitable options.

Read in detail about iec 61439 busbar calculation

Standard Dimension Trends Across Voltage Classes

Patterns appear when reviewing multiple versions of a busbar insulator size chart. Low voltage panels typically use compact supports between 25 mm and 60 mm tall because electrical spacing requirements are modest. Medium voltage assemblies require taller units with increased creepage distance.

In indoor environments with controlled humidity, shorter creepage paths may suffice. Outdoor or polluted settings demand larger profiles to reduce flashover risk. Engineers reviewing a busbar insulator size chart should therefore evaluate environmental severity alongside electrical parameters.

Material Selection and Performance Impact

While dimensions are central to the busbar insulator size chart, material choice also plays a major role. Epoxy resin insulators dominate modern switchgear because of their high mechanical strength and consistent dielectric properties. Porcelain variants remain in use where temperature extremes or ultraviolet exposure occur.

Get complete information about iec standard for busbar sizing

Composite materials have gained attention due to lightweight construction and resistance to cracking. When consulting a busbar insulator size chart, professionals should cross reference material specifications, especially when thermal cycling or vibration is expected.

Practical Steps for Selecting the Correct Size

Applying a busbar insulator size chart effectively requires structured evaluation rather than guesswork. The following approach mirrors common engineering practice.

Determine System Voltage and Insulation Level

Identify nominal voltage and insulation coordination requirements. Select entries from the busbar insulator size chart meeting or exceeding these values.

Evaluate Mechanical Load

Calculate busbar weight, short circuit forces, and spacing between supports. Compare the expected load with cantilever ratings in the busbar insulator size chart.

Verify Clearance and Creepage

Check that physical dimensions meet internal panel spacing guidelines and contamination category recommendations.

Confirm Mounting Compatibility

Ensure stud size and base diameter match structural provisions in the equipment layout.

Example Application Using a Busbar Insulator Size Chart

Consider a distribution panel operating at 415 V with copper busbars spaced at moderate intervals. Mechanical calculations estimate support load near 2 kN. By reviewing a busbar insulator size chart, an engineer might select a 50 mm tall insulator rated at 1.2 kV with 2.5 kN cantilever strength.

Find out more about iec 61439 busbar clearance

This choice provides adequate electrical margin and mechanical capacity without oversizing the component. The example demonstrates how referencing a busbar insulator size chart streamlines specification and reduces trial and error.

Expanded Comparison Table for Engineering Evaluation

To enhance decision making, engineers often compare multiple options simultaneously. The next reference table illustrates how different characteristics appear side by side in a typical busbar insulator size chart.

| Model Type | Height (mm) | Rated Voltage (kV) | Creepage Distance (mm) | Material | Recommended Application |

|---|---|---|---|---|---|

| LV Compact | 30 | 1 | 50 | Epoxy Resin | Control panels |

| LV Reinforced | 50 | 1.2 | 75 | Polyester | Distribution boards |

| MV Standard | 75 | 2 | 120 | Epoxy Resin | Switchgear sections |

| MV Extended | 90 | 3 | 150 | Porcelain | Outdoor cabinets |

| Heavy Duty | 120 | 5 | 200 | Composite | Industrial substations |

Reviewing such a busbar insulator size chart enables engineers to align physical space, durability, and insulation performance with project needs.

Find out more about Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

Installation Considerations That Influence Size Choice

Selection does not end with referencing a busbar insulator size chart. Installation practices also affect performance. Torque application on studs should follow manufacturer recommendations to avoid cracking. Surfaces must remain clean before mounting to maintain dielectric integrity.

Engineers should consider ventilation and thermal expansion as well. Oversized conductors may exert additional stress on supports, making mechanical margins from the busbar insulator size chart especially valuable.

Maintenance and Inspection Implications

Routine inspection extends service life. Dust accumulation, discoloration, or hairline fractures indicate deterioration. Maintenance teams frequently consult the original busbar insulator size chart during replacement planning to ensure compatibility with installed hardware.

Maintaining accurate documentation of selected sizes simplifies future upgrades and prevents mismatch during spare procurement.

Find out more about High Impedance Busbar Protection Explained with Example Calculations

Common Mistakes When Using a Busbar Insulator Size Chart

Even experienced professionals sometimes misinterpret data tables. One frequent issue is focusing only on voltage rating while ignoring mechanical strength. Another is overlooking creepage distance in polluted environments.

Cross checking every parameter listed in the busbar insulator size chart avoids under specification. Engineers should also verify units and standards, since international manufacturers may present values differently.

Final Thoughts

The role of proper insulation support extends far beyond simple mechanical mounting. Reliability, safety, and long term system stability depend on informed component selection. A busbar insulator size chart serves as a practical engineering tool that consolidates dimensions, ratings, and performance data into a usable format.

By understanding how to interpret these charts, comparing parameters methodically, and aligning choices with real operating conditions, engineers can ensure dependable busbar installations in both industrial and commercial applications. Whether designing new assemblies or maintaining existing infrastructure, consistent use of a busbar insulator size chart remains an essential part of professional electrical engineering practice.

Find out more about Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#BusbarInsulatorSizeChart, #ElectricalDesign, #PowerDistribution, #SwitchgearEngineering, #BusbarInsulators, #ElectricalStandards, #EngineeringReference, #PanelDesign, #PowerSystemEngineering, #ElectricalGuide