Busbar Distance Calculation – Complete Guide, Formula, Standards & Design Tips

Busbar distance calculation is a critical part of electrical power system design because it directly influences safety, thermal performance, insulation coordination, and equipment reliability. Engineers working on switchgear, substations, panel boards, and industrial distribution systems must evaluate clearances carefully to avoid flashover, overheating, and mechanical stress. A well-executed busbar distance calculation ensures compliance with international standards while also improving long-term operational stability.

Table of Contents

In practical installations, conductors carrying high current must be spaced correctly to withstand voltage stress, environmental conditions, and short-circuit forces. This article explains the principles behind busbar distance calculation, covering formulas, factors affecting spacing, recommended values, applicable standards, and design tips used in professional projects. The goal is to give a clear understanding that can be applied in real engineering scenarios without unnecessary complexity.

Understanding the Importance of Busbar Distance Calculation

Busbars distribute power between feeders, transformers, and protection devices. Their spacing determines insulation strength and heat dissipation capability. Busbar distance calculation is therefore not just a theoretical exercise but a design step that prevents faults such as phase-to-phase flashover and tracking.

Find all about Busbar Size Chart in mm

When spacing is too small, electric field stress increases and may cause breakdown under transient overvoltage. If spacing is excessive, panels become bulky and expensive. Engineers aim to balance electrical clearance, mechanical strength, and economic efficiency. Correct busbar distance calculation also supports coordination with enclosure size, ventilation requirements, and cable routing.

Some common applications where this process is essential include low voltage switchboards, medium voltage metal-clad panels, and outdoor air-insulated substations. Each environment introduces its own constraints and assumptions.

Factors Affecting Busbar Spacing

Several technical and environmental parameters influence busbar distance calculation. These factors must be reviewed together rather than in isolation.

| Factor | Influence on Spacing | Practical Consideration |

|---|---|---|

| System Voltage | Higher voltage demands greater clearance | Determines base insulation distance |

| Insulation Medium | Air, SF6, or solid insulation changes dielectric strength | Air requires larger spacing |

| Altitude | Reduced air density lowers breakdown strength | Apply correction factor |

| Temperature | Affects conductor expansion and cooling | Allow mechanical tolerance |

| Short Circuit Level | Generates electrodynamic forces | Ensure mechanical stability |

| Pollution Level | Dust or humidity reduces insulation capability | Increase creepage distance |

A complete busbar distance calculation incorporates these parameters to ensure that operational and environmental stress does not compromise system performance.

Find all about Busbar Bending Calculation

Basic Formula Used in Busbar Distance Calculation

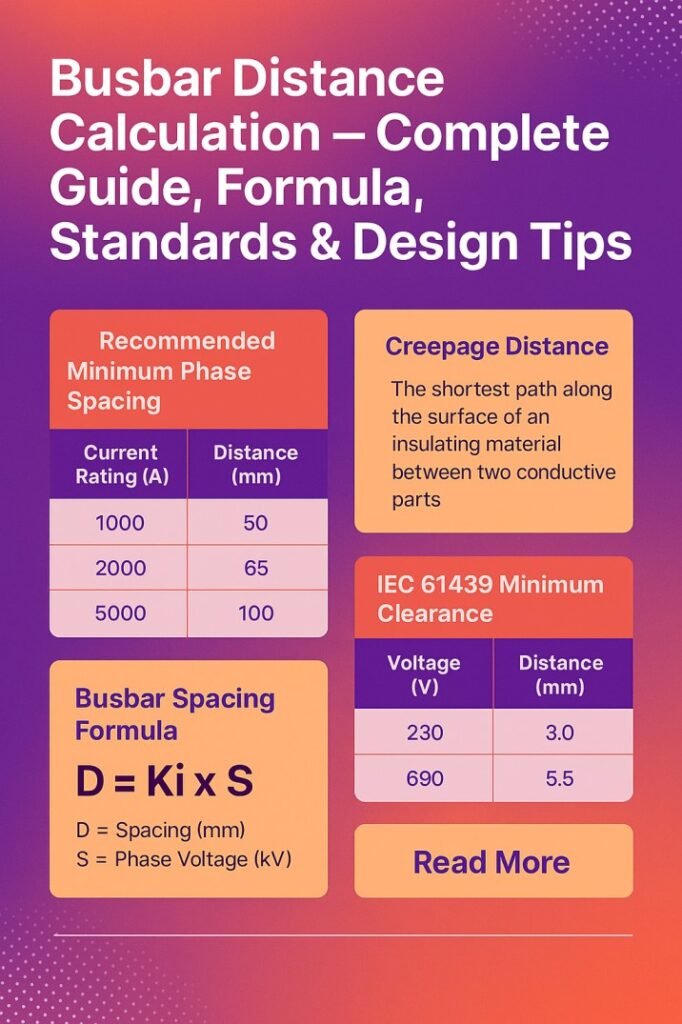

Although standards often provide recommended values, analytical estimation can guide preliminary design. One widely used approach is based on dielectric strength in air.

Minimum clearance can be estimated by:

Minimum Distance = System Voltage / Dielectric Strength of Air

Where dielectric strength of air is commonly taken as about 3 kV per mm under standard conditions. Engineers usually include a safety factor.

For example:

| Parameter | Value |

|---|---|

| System Voltage | 11 kV |

| Air Strength | 3 kV/mm |

| Calculated Clearance | 3.67 mm |

| With Safety Margin | 10–12 mm practical design |

This simplified method is only a starting point. Real busbar distance calculation must follow standard tables and insulation coordination rules, especially for medium and high voltage installations.

Find out more about Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

Standard Clearance Values for Reference

Industry standards provide validated spacing recommendations derived from testing and operational history. Engineers often refer to them before finalizing layouts.

| Voltage Level | Typical Phase Clearance in Air |

|---|---|

| 415 V | 25–40 mm |

| 3.3 kV | 60–80 mm |

| 11 kV | 120–160 mm |

| 33 kV | 320–360 mm |

These values vary depending on enclosure design and environmental classification. During busbar distance calculation, always verify against the specific standard applicable to the project region.

Find out more about High Impedance Busbar Protection Explained with Example Calculations

Relevant International Standards

Professional engineers align busbar distance calculation with established codes to ensure regulatory compliance and safety certification. Frequently referenced standards include:

- IEC 61439 for low voltage switchgear assemblies

- IEC 62271 for high voltage equipment

- IEEE C37 guidelines for metal enclosed switchgear

- NFPA recommendations for electrical installations

These documents specify air clearance, creepage distance, insulation levels, and testing requirements. Applying them correctly ensures that spacing decisions are accepted by inspection authorities and clients.

Creepage Distance Versus Clearance

Busbar distance calculation involves two different but related concepts. Clearance refers to the shortest path through air between conductors, while creepage distance refers to the path along insulating surfaces. Both must be evaluated.

Find out more about Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

| Parameter | Definition | Importance |

|---|---|---|

| Clearance | Direct air gap between live parts | Prevents flashover |

| Creepage | Surface path along insulation | Avoids tracking |

| Coordination | Selection of both values together | Ensures reliability |

Ignoring creepage considerations in dusty or humid environments can result in insulation degradation even if air spacing appears sufficient. Balanced busbar distance calculation therefore addresses both dimensions.

Design Tips from Practical Engineering Experience

Experienced designers apply certain guidelines that go beyond formulas and tables. These considerations improve reliability and simplify installation.

- Maintain symmetrical spacing between phases to reduce electromagnetic imbalance.

- Allow expansion margins for copper or aluminum bars under temperature rise.

- Avoid sharp edges that concentrate electric field stress.

- Ensure proper support spacing to withstand mechanical forces during faults.

- Verify accessibility for maintenance and inspection.

Integrating these practices into busbar distance calculation helps create systems that perform well under real operating conditions.

Find out more about iec 61439 busbar clearance

Busbar Arrangement and Orientation

Physical layout also affects spacing decisions. Flat, vertical, or sandwich configurations influence heat dissipation and insulation stress distribution. Engineers often evaluate multiple arrangements during busbar distance calculation.

| Arrangement | Advantages | Limitation |

|---|---|---|

| Horizontal Flat | Easy installation | Larger panel width |

| Vertical Stack | Space efficient | Cooling considerations |

| Sandwich Type | Compact magnetic balance | Complex insulation design |

Selecting the correct orientation ensures that calculated distances remain effective once installed inside the enclosure.

Get complete information about iec standard for busbar sizing

Thermal and Mechanical Considerations

Electrical clearance alone does not complete busbar distance calculation. Current carrying capacity generates heat, causing expansion and possible deformation. Short circuit conditions create strong magnetic forces that may bend conductors.

Thermal rise studies confirm that spacing allows airflow and cooling. Mechanical calculations verify support strength. Combining these aspects produces a comprehensive design rather than a purely theoretical value.

Common Mistakes to Avoid

Engineers sometimes underestimate the complexity of busbar distance calculation. Typical issues include relying only on theoretical formulas, ignoring altitude correction, and overlooking contamination effects. Another frequent mistake is neglecting tolerance for manufacturing variation, which may reduce actual spacing below intended values.

Read in detail about iec 61439 busbar calculation

Ensuring accurate measurements, proper documentation, and adherence to tested standards prevents these errors and improves project acceptance during commissioning.

Conclusion

Busbar distance calculation forms the backbone of safe and efficient power distribution design. By understanding voltage stress, insulation properties, environmental conditions, and mechanical forces, engineers can determine spacing that balances reliability and cost. Applying formulas for initial estimates, validating results against standards, and considering layout constraints ensures robust system performance.

A disciplined approach to busbar distance calculation supports long service life, minimizes risk of electrical faults, and enhances maintainability. Whether working on industrial panels or utility substations, mastering this process remains an essential skill for electrical professionals aiming to deliver dependable infrastructure.

Know more about IEC Standard for Busbar Clearance

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#busbardistancecalculation, #busbardesign, #electricalengineering, #powersystems, #switchgeardesign, #busbarspacing, #electricalcalculations, #engineeringtools, #substationdesign, #industrialpower