Busbar Contact Resistance Test: Step by Step Guide

A busbar contact resistance test is one of the most important diagnostic checks for power distribution systems. When busbars carry high current, even a small increase in resistance at joints can cause overheating, energy losses, and long-term equipment failure. Because of this, engineers perform routine testing to confirm that all bolted joints, connectors, and conductive interfaces remain healthy.

Table of Contents

This step-by-step guide explains how the test is carried out, which instruments are used, and which IEC standards govern the procedure. It also highlights practical methods followed in the field to ensure accuracy and safety.

Why the Busbar Contact Resistance Test Matters

Busbars operate under heavy electrical and mechanical stress. Any poor connection, loose joint, corroded surface, or degraded contact plate can lead to a rise in localized resistance. When resistance increases, the joint heats up under load. Over time, this can damage insulation, deform copper or aluminum conductors, and compromise the entire switchgear assembly. Dive deeper into contact resistance measurement test

Performing a contact resistance test helps detect these problems early. It offers a reliable measurement of how effectively current flows across connected parts.

Apparatus Used for Busbar Contact Resistance Testing

To perform this test correctly, specialized equipment is needed. The main instruments are listed below.

Digital Micro-Ohmmeter

A micro-ohmmeter is the primary tool. It injects a stable, high DC test current and measures the resulting voltage drop. Typical currents range from 10 A to 600 A depending on busbar size. The instrument displays resistance values in micro-ohms.

Four-Terminal Kelvin Test Leads

The Kelvin method uses two leads for current injection and two separate leads for voltage measurement. This eliminates errors caused by cable and contact resistance in the test setup. Kelvin clamps, probes, and heavy-duty connectors are used depending on joint type. Get complete information about contact resistance test

Temperature Measuring Device

Temperature affects resistance. A thermometer or infrared temperature gun is used to record ambient and surface temperature so values can be corrected or referenced according to standards.

Torque Wrenches and Cleaning Tools

Before testing, joints may need to be tightened or cleaned. Torque wrenches ensure bolts are secured to manufacturer specifications. Cleaning tools such as non-abrasive brushes remove oxidation without damaging the surface.

Safety Gear

Electrical gloves, insulated mats, face shields, and lockout-tagout (LOTO) kits are required to maintain safety during de-energized testing.

IEC Standards Related to Busbar Contact Resistance Test

The International Electrotechnical Commission provides guidelines for low-resistance testing and contact joint performance. The most relevant IEC documents include:

IEC 60404 and IEC 60239

These standards cover methods for measuring low resistance values in conductive materials and electrical joints. The four-terminal or Kelvin technique recommended in these documents is the industry standard for busbar testing. Learn more about circuit breaker contact resistance test

IEC 61439

This standard applies to low-voltage switchgear and controlgear assemblies. It specifies requirements for busbar design, joints, temperature rise limits, and verification procedures. Contact resistance testing is part of routine verification and maintenance under this standard.

IEC 60060-2 and IEC 60038

Although focused on dielectric tests and standard voltages, these documents support broader validation procedures in which contact resistance testing is often combined with insulation and continuity checks.

In practical settings, manufacturers may also provide additional guidelines for maximum allowable resistance values across joints.

Understanding Acceptable Resistance Values

Busbar joints are designed to have very low resistance. The exact permissible value depends on conductor material, cross-section, and design. The table below illustrates typical reference values used in the field.

| Busbar Material | Typical Joint Resistance Range (Micro-ohms) | Notes |

|---|---|---|

| Copper | 10–50 µΩ | Clean, tight joints |

| Aluminum | 20–80 µΩ | Higher due to oxide layer |

| Plated Busbars | 5–30 µΩ | Silver/ tin coatings lower resistance |

Values outside these ranges may indicate poor contact pressure, contamination, or deteriorating components.

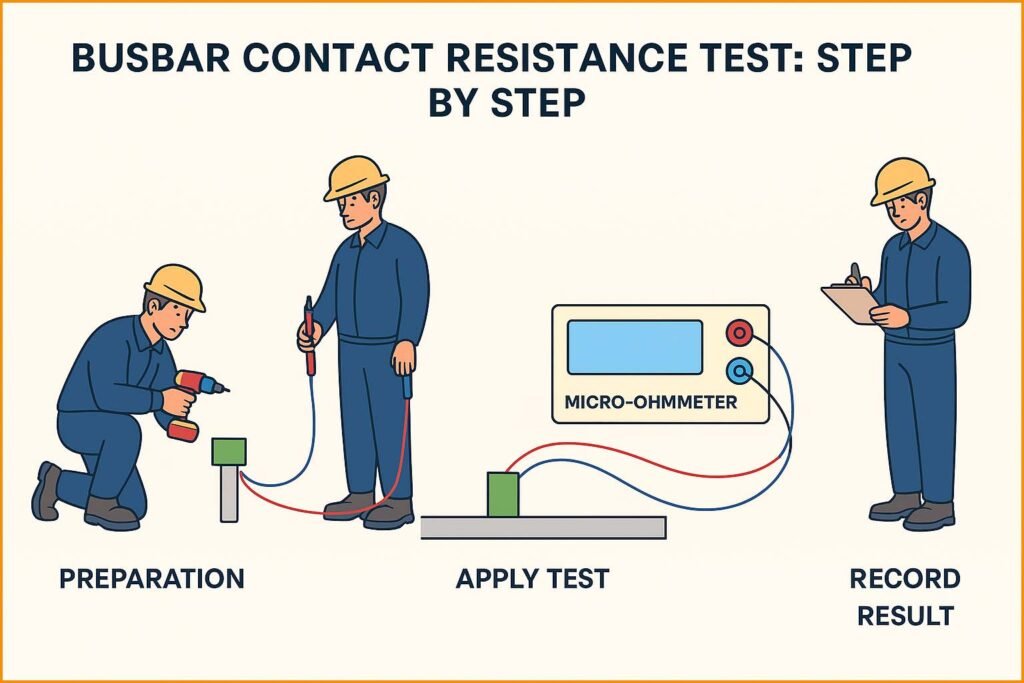

Step-by-Step Busbar Contact Resistance Test Procedure

This section describes a full procedure followed in industrial plants, substations, and switchgear installations.

Step 1: Isolate and De-energize the System

Ensure the busbar section is completely isolated from the power source. Apply lockout-tagout devices to prevent accidental energization. Verify absence of voltage using a calibrated tester. Safety clearance must be confirmed before any manual contact with the busbars.

Step 2: Inspect the Busbar Joints

Perform a visual inspection. Look for oxidation, discoloration, loose bolts, or contamination. A clean and well-prepared joint ensures accurate resistance measurement. If necessary, use approved cleaning tools and tighten bolts with the recommended torque. Explore details on contact resistance measurement

Step 3: Prepare the Micro-Ohmmeter

Set up the digital micro-ohmmeter near the test area. Select an appropriate test current based on busbar size. Higher currents provide better measurement resolution but must match equipment ratings. Ensure Kelvin leads are intact and properly connected.

Step 4: Connect the Kelvin Leads

Attach current injection leads on each side of the joint. Then connect the voltage sensing leads as close as possible to the joint interface. This ensures that only the joint resistance—not the conductor length—is measured. Poor placement of the voltage sense leads is a common cause of inaccurate results.

Step 5: Stabilize the Test Current

Start the test. Allow a few seconds for the current to stabilize. The instrument will calculate resistance from the voltage drop. Observe whether readings fluctuate. Stable readings indicate good contact and consistent measurement.

Step 6: Record the Resistance Value

Document the micro-ohm reading, test current, ambient temperature, and joint location. Many micro-ohmmeters provide automatic data logging. Proper documentation is essential for future trending and preventive maintenance. Find out more about contact resistance test acceptable value for busbar

Step 7: Repeat the Test for All Joints

Every bolted connection in the busbar system should be tested. This includes horizontal and vertical joints, tap-offs, and transition pieces. Consistency across readings indicates uniform installation quality.

Step 8: Compare Results with Standards and Previous Data

Compare the measured value against manufacturer recommendations or IEC reference guidelines. Also review past test results if available. An increasing trend over time may indicate loose joints, corrosion, or aging.

Step 9: Investigate High Resistance Findings

If a joint shows abnormally high resistance, re-inspect it. Check for improper torque, surface contamination, misalignment, or damaged hardware. After corrective action, repeat the measurement. Never energize a busbar with a known high-resistance joint.

Common Causes of High Contact Resistance

Understanding the root causes helps maintain busbar reliability. Frequent issues include:

• Loose bolted joints

• Mechanical vibration leading to reduced contact pressure

• Oxide formation on aluminum or copper surfaces

• Poor surface preparation during installation

• Misaligned or warped busbar plates

• Worn or aged contact surfaces

• Corrosion due to moisture or environmental conditions

Addressing the root cause reduces long-term thermal stress and prevents failures. Discover everything about contact resistance test acceptable value

Best Practices to Ensure Accurate Test Results

Engineers follow several best practices to achieve dependable results. Use the Kelvin four-terminal method without exception. Always test with the correct current value to ensure a readable voltage drop. Keep connections clean and tight.

Maintain consistent contact placement of leads. Perform measurements at stable temperatures. Use calibrated instruments and verify settings before each test. Document every reading to build a useful maintenance record.

How the Test Supports Predictive Maintenance

The busbar contact resistance test is a key element of predictive and preventive maintenance programs. Trending micro-ohm values over time helps identify early degradation. It also supports asset management decisions by revealing when a joint requires reconditioning or replacement. In critical installations like substations, data centers, and industrial plants, the test reduces unplanned outages by providing early warnings of thermal stress at joints. Learn more about contact resistance test iec standard

Conclusion

A busbar contact resistance test is a straightforward yet vital procedure for ensuring the integrity of electrical distribution systems. By applying the Kelvin four-terminal method, using the right testing apparatus, and following relevant IEC standards, engineers can obtain accurate measurements and maintain system reliability.

Regular testing prevents overheating, extends the life of busbars, and supports a safe and efficient power network. When combined with proper maintenance practices, it becomes a powerful diagnostic tool that protects equipment and reduces operational risks.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#busbarcontactresistancetest, #contactresistancetest, #busbarsystem, #electricaltesting, #powerequipmenttesting, #lowresistancemeasurement, #electricalmaintenance, #electricalsafety, #IECstandards, #switchgeartesting