Thermal Fuses: Important Parameters & Selection Table

Thermal fuses, often referred to as thermal cutoffs or TCOs, are crucial components in the realm of electronics and electrical engineering. These devices are ingeniously designed to ensure the safety and reliability of various systems by monitoring and controlling temperatures.

These fuses are the unsung heroes that prevent overheating-related disasters and maintain the integrity of appliances, industrial equipment, and electronic circuits.

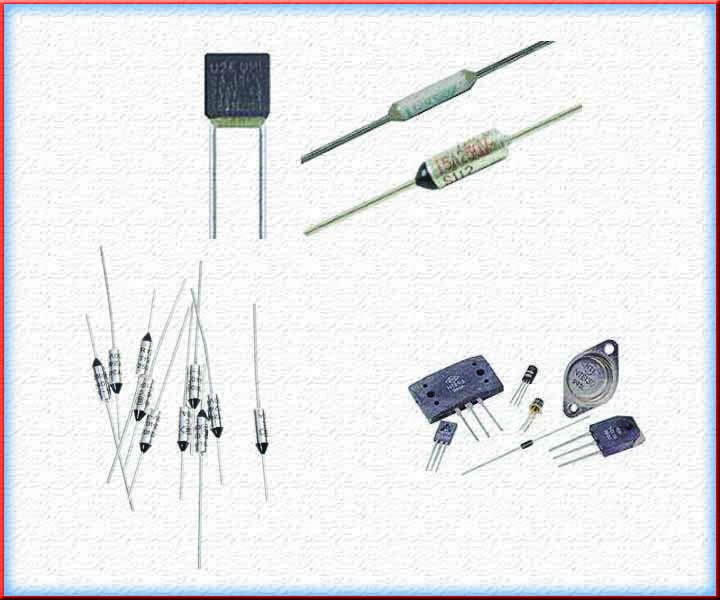

What are Thermal Fuses

At the heart of their functionality, thermal fuses are fundamentally simple yet brilliantly effective. Their primary function revolves around monitoring the temperature of their surroundings and taking decisive action when this temperature exceeds a predetermined threshold. This threshold is pre-set during the manufacturing process, and it forms the core determinant of the thermal fuse’s operation.

When the temperature surpasses this critical point, the fuse promptly interrupts the flow of electric current, essentially acting as a circuit breaker specifically attuned to temperature fluctuations.

Parameters of Thermal Fuse

Temperature Rating: This parameter is the cornerstone of fuse functionality. It signifies the temperature level at which it will trigger its action. Available in a spectrum of temperature ratings, these fuses are adaptable to various applications, ensuring precise protection against overheating.

Current Rating: The current rating outlines the maximum electrical current that a thermal fuse can withstand without activation. It’s imperative to select a fuse with a current rating that aligns with the maximum current the protected circuit will experience.

Response Time: The response time is the duration it takes to initiate action after its temperature threshold is crossed. Swift response times are essential in swiftly curbing any dangerous temperature spikes.

Voltage Rating: The voltage rating reflects the highest voltage that the fuse can safely manage. Proper alignment of the voltage rating with the application’s requirements is vital to ensure optimal protection.

Selection Table for Thermal Fuses

Here’s a simplified selection table for thermal fuse based on current and voltage ratings. Keep in mind that this table is for illustrative purposes and should not be used as an exhaustive guide for all thermal fuse applications. Always refer to manufacturer specifications and guidelines for accurate selection.

| Current Rating (A) | Voltage Rating (V) | Example Applications |

| 1 – 5 | 120 – 250 | Small household appliances, electronics |

| 5 – 10 | 250 – 600 | Heaters, power tools, industrial machinery |

| 10 – 20 | 600 – 1000 | HVAC systems, industrial motors, heavy machinery |

| 20 – 30 | 1000 – 1500 | Large motors, transformers, high-power equipment |

| 30 – 50 | 1500 – 2000 | Energy distribution systems, industrial equipment |

Please note that the values in this table are general ranges and can vary based on specific thermal fuse models and manufacturers.

Applications of Thermal Fuses

Thermal fuses find themselves indispensable in a plethora of applications across diverse industries:

Household Appliances: They are commonly integrated into household appliances like coffee makers, toasters, and microwave ovens, safeguarding these devices from potential fire hazards resulting from excessive temperatures.

HVAC Systems: Heating, ventilation, and air conditioning systems often incorporate thermal fuses to prevent overheating of components, ensuring the safety and efficiency of the system.

Electrical Motors: Motors used in various industrial settings rely on thermal fuses to avoid damage due to overheating. This is particularly crucial in environments where continuous operation is required.

Power Supplies: Thermal fuses play a pivotal role in power supplies, regulating temperatures to prevent catastrophic failures and disruptions in critical applications.

Battery Packs: In the realm of rechargeable batteries, thermal fuses are integral to averting thermal runaway and potential explosions caused by excessive heat generation.

In the ever-evolving landscape of electronics and engineering, thermal fuses stand as the silent sentinels of safety, diligently protecting systems from the risks of overheating. Their ability to deftly detect and respond to temperature changes ensures the seamless operation of appliances, equipment, and circuits, contributing to enhanced longevity and reliability.

With their critical parameters fine-tuned to specific applications, thermal fuses remain essential components for upholding safety and stability in the face of temperature-induced challenges.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#ThermalFuses, #ThermalProtection, #CircuitProtection, #ElectricalSafety, #ThermalCutoff, #OverheatProtection, #ElectronicsRepair, #HomeAppliances, #FuseTechnology, #ThermalSwitch, #ElectricalEngineering, #OvercurrentProtection, #HeatSensitiveSwitch, #ElectricalComponents, #DIYRepairs