Transformer Testing Methods | Important Professional Guide for Power Engineers

Transformer testing methods form the backbone of reliability and safety in modern power systems. Every power engineer working with generation, transmission, or industrial distribution networks understands that proper verification ensures stable performance and long service life. From factory acceptance to routine maintenance, transformer testing methods help confirm insulation health, winding integrity, and operational efficiency. This guide explains practical transformers testing methods in a clear and professional manner so engineers can apply them confidently in real environments.

Table of Contents

Understanding the Importance of Transformer Testing

Transformers operate under thermal, electrical, and mechanical stress. Over time, insulation deteriorates, winding resistance shifts, and dielectric strength may weaken. Structured transformer testing methods allow engineers to detect faults early and avoid catastrophic failures. These tests support commissioning activities, predictive maintenance, and troubleshooting during operation.

Power engineers rely on transformer testing methods to validate design parameters, ensure compliance with standards, and verify energy efficiency. Routine application of these methods reduces unexpected outages and protects costly infrastructure. Whether working with distribution units or large power transformers, testing practices follow similar principles.

Know more about Transformer Oil Testing: 9 Important Tests for Healthiness

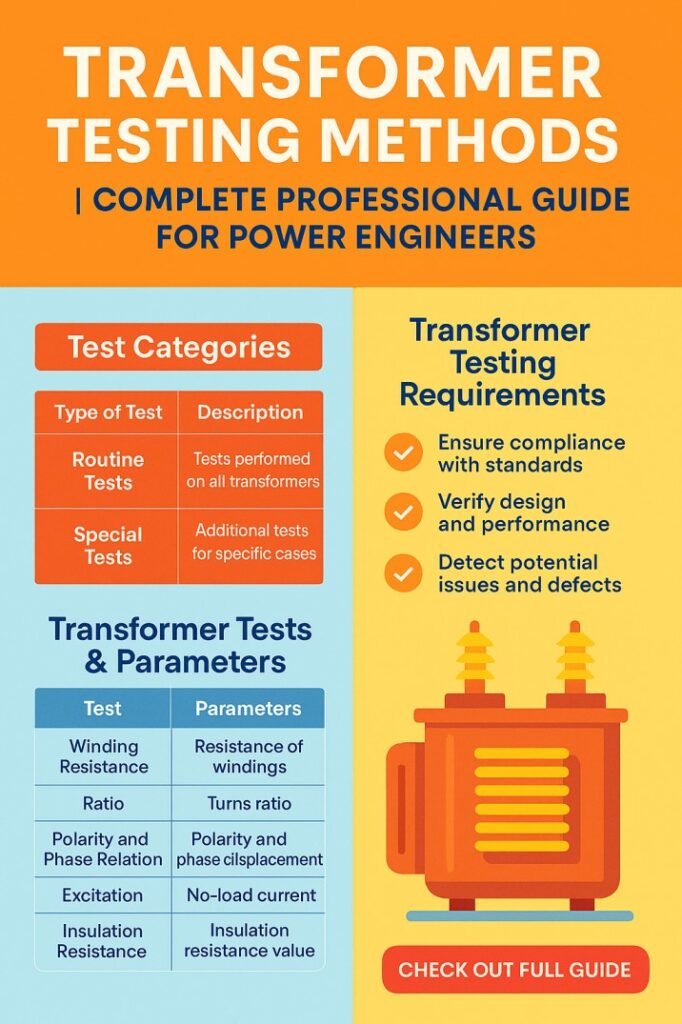

Classification of Transformer Testing Methods

Transformer testing methods can be broadly categorized based on purpose and stage of use. Each category provides insight into specific electrical or mechanical characteristics. The table below summarizes the main classifications.

| Category | Objective | Typical Application Stage | Examples |

|---|---|---|---|

| Routine Tests | Confirm manufacturing quality | Factory stage | Ratio test, polarity check |

| Type Tests | Validate design performance | Prototype evaluation | Temperature rise, impulse test |

| Special Tests | Meet customer specifications | Project requirement | Noise level measurement |

| Field Tests | Assess operational health | Installation or maintenance | Insulation resistance, oil analysis |

These transformer testing methods collectively ensure compliance with technical standards and operational readiness before energization.

Know more about Top 20 Electrical Testing Tools Which You Must Have

Visual Inspection and Preliminary Checks

Before advanced transformers testing methods begin, a thorough inspection is essential. Engineers examine bushings, cooling radiators, and tap changer connections. Oil level indicators and grounding arrangements are verified. This stage may appear simple, yet it often reveals mechanical damage or shipping issues.

Visual evaluation complements other transformer testing methods by identifying obvious abnormalities. A structured checklist ensures no element is overlooked and prepares the transformer for electrical testing. Find all about Partial Discharge vs Tan Delta Cable Testing: Important Key Differences Every Engineer Must Know

Insulation Resistance Measurement

Among widely applied transformer testing methods, insulation resistance measurement provides immediate feedback on insulation condition. Using a megohmmeter, engineers measure resistance between windings and ground. Results indicate moisture presence or contamination within insulation systems.

| Test Voltage | Equipment Type | Expected Outcome |

|---|---|---|

| 500 V DC | Small distribution transformer | Stable high resistance |

| 1 kV DC | Medium rating transformer | Consistent readings |

| 5 kV DC | Large power transformer | Very high resistance values |

Consistent records of insulation resistance strengthen predictive maintenance strategies. When transformer testing methods show declining trends, corrective action can be scheduled.

Know more about Best Megger Testers for Industrial Use

Turns Ratio and Polarity Verification

Turns ratio measurement confirms that winding ratios match design values. These transformer testing methods use specialized ratio meters to compare primary and secondary voltages. Correct ratio ensures proper voltage transformation and load sharing.

Polarity verification complements ratio measurement by ensuring correct phase relationships. Incorrect polarity can result in circulating currents when transformers operate in parallel. Applying transformer testing methods in this stage avoids major operational issues later.

Winding Resistance Testing

Winding resistance evaluation is another essential element of transformer testing methods. It detects loose connections, damaged conductors, or tap changer problems. Measurements are taken with precision instruments supplying stable DC current.

Know more about Insulation Resistance Testing: Step-by-Step Process

| Parameter | Purpose | Engineering Insight |

|---|---|---|

| Phase Resistance | Detect imbalance | Identifies contact issues |

| Temperature Correction | Standardize results | Enables comparison |

| Tap Position Recording | Verify continuity | Ensures tap changer health |

Accurate interpretation of results improves fault diagnosis and extends equipment life.

Dielectric and Power Factor Testing

Dielectric strength assessment is a critical stage in transformer testing methods. Power factor or dissipation factor tests evaluate insulation losses and capacitance behavior. These values indicate insulation aging or contamination.

Engineers rely on transformer testing methods in this area to determine if insulation requires drying or oil treatment. High loss values suggest deterioration, prompting corrective maintenance. Regular monitoring ensures safe energization conditions.

Know more about Top 12 Electrical Testing Equipment Suppliers in USA

Oil Quality and Dissolved Gas Analysis

Liquid-filled transformers depend on insulating oil performance. Transformer testing methods include laboratory examination of oil samples to evaluate moisture content, acidity, and dielectric breakdown voltage. Dissolved gas analysis reveals fault signatures such as overheating or arcing.

| Gas Detected | Possible Condition | Recommended Action |

|---|---|---|

| Hydrogen` | Partial discharge | Inspect insulation |

| Methane | Thermal fault | Monitor loading |

| Acetylene | Arcing | Immediate investigation |

These transformer testing methods provide early warning signals and support data-driven maintenance decisions.

Short Circuit and Impedance Measurement

Impedance testing measures voltage drop and leakage reactance characteristics. Transformer testing methods applied here verify mechanical stability of windings and confirm design specifications. Deviations may indicate deformation after fault events.

Know more about Power Quality Analyzer Buying Guide for Engineers

Short circuit verification also ensures safe current handling capability. Engineers integrate these transformer testing methods into commissioning processes to validate performance under simulated fault conditions.

Temperature Rise and Load Testing

Thermal performance evaluation represents advanced transformer testing methods used during type testing or major refurbishment. Engineers operate the transformer under controlled load to observe heat distribution and cooling system response.

Monitoring temperature rise ensures compliance with insulation limits and confirms operational reliability. Effective transformer testing methods in this domain protect insulation longevity and maintain system efficiency.

Partial Discharge Measurement

Partial discharge detection is among sophisticated transformer testing methods applied to identify microscopic insulation breakdown. Specialized sensors measure discharge activity under high voltage conditions. Early detection prevents insulation failure and prolongs equipment life.

Know more about High Voltage Testing Procedures for Electrical Panels: Step by Step

This technique enhances predictive maintenance programs and complements other transformer testing methods aimed at insulation monitoring.

Best Practices for Effective Testing

Applying transformer testing methods effectively requires structured planning and safety awareness. Engineers should follow established procedures, calibrate instruments, and document results thoroughly. Consistency in methodology improves data comparison over time. Explore all about vlf testing procedure

| Practice | Benefit |

|---|---|

| Standardized Test Sequence | Reliable comparisons |

| Proper Grounding | Operator safety |

| Accurate Record Keeping | Trend analysis |

| Environmental Control | Measurement accuracy |

Adhering to these practices maximizes the value obtained from transformer testing methods and strengthens system reliability.

Know more about VLF Testing vs Hipot: Best Guide on Key Differences and Applications

Conclusion

Transformer testing methods remain essential for ensuring operational security, efficiency, and regulatory compliance in power systems. From visual checks to advanced diagnostic measurements, each technique provides insight into transformer condition and performance. Engineers who understand transformer testing methods can detect developing issues early and make informed maintenance decisions.

Consistent application of transformer testing methods enhances equipment lifespan, reduces downtime, and protects investment in electrical infrastructure. By integrating systematic testing into routine engineering practice, power professionals uphold reliability standards and maintain stable energy delivery.

Find all about High Voltage Cable Testing Standards: Complete Guide for Engineers

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerTestingMethods, #TransformerTesting, #PowerSystemTesting, #ElectricalEngineering, #SubstationMaintenance, #HighVoltageTesting, #TransformerDiagnostics, #EngineeringStandards, #GridReliability, #PowerEquipment