Busbar Heating Calculation | Important Guide for Electrical Design & Thermal Analysis

Busbars are the backbone of modern power distribution systems. From low voltage panels to high capacity substations, they carry large currents and must operate within safe temperature limits. A proper busbar heating calculation helps engineers confirm that copper or aluminum conductors will not exceed allowable temperature rise during operation. When this analysis is done correctly, it prevents insulation damage, improves reliability, and supports compliance with electrical standards.

Table of Contents

This guide explains the fundamentals of busbar heating calculation in practical terms. It focuses on electrical losses, thermal behavior, and real design considerations that engineers encounter in switchgear, panel boards, and industrial installations. The discussion remains simple and readable while still covering technical depth for professional use.

Understanding the Purpose of Busbar Heating Calculation

Before sizing a busbar, engineers evaluate both current carrying capacity and temperature rise. The busbar heating calculation estimates how much heat develops due to current flow and how efficiently that heat dissipates into the surrounding environment.

Find all about Busbar Size Chart in mm

Electrical conductors produce heat mainly because of resistance. As current increases, the losses grow rapidly and the conductor temperature rises. If the temperature exceeds insulation or material limits, deformation, oxidation, or failure may occur. The calculation therefore supports these objectives:

- Ensuring thermal stability under full load

- Maintaining compliance with IEC or IEEE temperature limits

- Improving equipment lifespan

- Avoiding excessive voltage drop

- Optimizing conductor sizing and cost

In practical projects, this evaluation becomes part of switchgear design validation, especially for high current feeders and bus duct systems.

Key Factors Affecting Busbar Temperature Rise

Several physical and electrical variables influence heating behavior. A complete busbar heating calculation considers these parameters rather than relying on simplified current tables.

| Factor | Description | Design Impact |

|---|---|---|

| Material Type | Copper or aluminum conductivity | Copper generates less heat |

| Current Magnitude | RMS current flowing | Heating rises with current square |

| Cross Section | Width and thickness of bar | Larger area lowers resistance |

| Ambient Temperature | Surrounding air temperature | Higher ambient reduces cooling |

| Installation Method | Enclosed or open air mounting | Enclosures trap heat |

| Surface Finish | Tin plating or bare metal | Affects emissivity |

| Spacing Between Bars | Phase clearance distance | Influences airflow |

Each factor interacts with others. For example, a bar inside a sealed panel at high ambient temperature requires more conservative design margins than an open air installation.

Find all about Busbar Bending Calculation

Electrical Losses Used in Busbar Heating Calculation

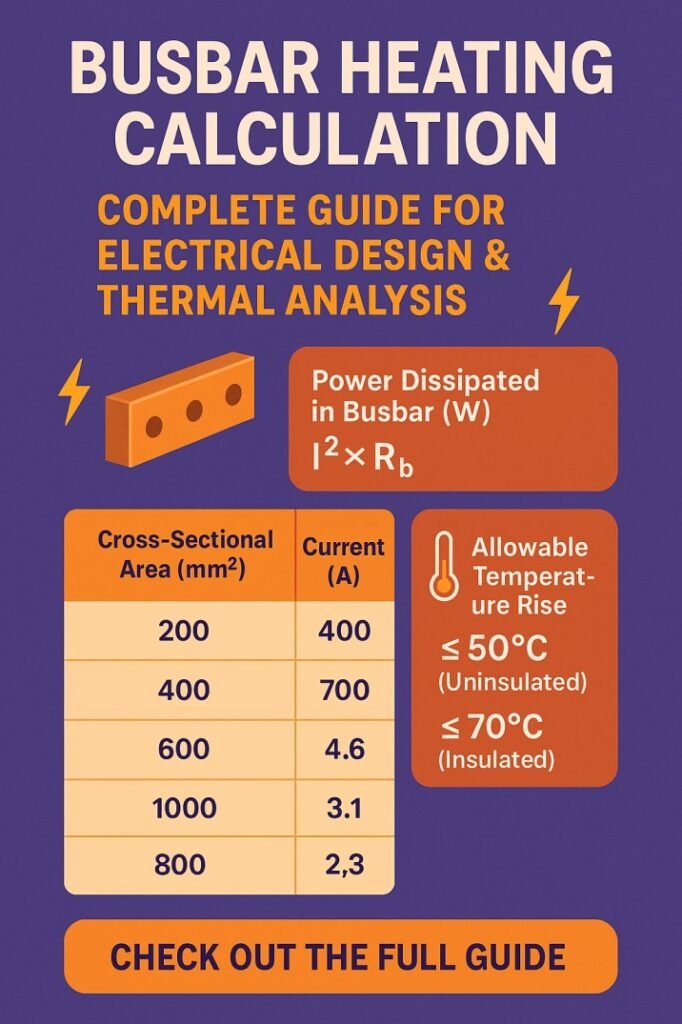

The core of busbar heating calculation lies in estimating power loss caused by conductor resistance. The fundamental equation is derived from Joule heating principles.

Power loss in watts can be expressed as:

P = I²R

Where current squared multiplies the effective resistance of the busbar length. Resistance depends on material resistivity and geometry.

| Parameter | Symbol | Typical Unit |

|---|---|---|

| Current | I | Ampere |

| Resistance | R | Ohm |

| Power Loss | P | Watt |

| Length | L | Meter |

| Resistivity | ρ | Ohm meter |

Resistance is calculated using:

R = ρL / A

Here A represents cross sectional area. This relationship shows why increasing thickness or width directly reduces heating. When engineers perform busbar heating calculation, they adjust dimensions until losses remain within acceptable limits.

Find out more about Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

Thermal Balance and Temperature Estimation

Once electrical loss is known, the next step estimates temperature rise. Heat generated inside the conductor must equal heat dissipated through convection and radiation when steady state is reached.

In simplified engineering practice, temperature rise can be approximated using empirical formulas or manufacturer data derived from testing. The concept follows:

Temperature rise ∝ Power loss / Heat dissipation capability

Factors affecting dissipation include airflow, enclosure design, and mounting orientation. In panel design, conservative correction factors are often applied to account for limited ventilation. This practical method keeps busbar heating calculation realistic for field conditions.

Material Comparison in Busbar Heating Calculation

Copper and aluminum dominate industrial installations. Both require slightly different treatment during analysis because of conductivity differences.

| Property | Copper | Aluminum |

|---|---|---|

| Electrical Conductivity | Higher | Lower |

| Density | Higher | Lower |

| Cost | Higher | Lower |

| Expansion Rate | Moderate | Higher |

| Heating Tendency | Lower | Higher |

When performing busbar heating calculation, aluminum typically needs larger cross sectional area to carry the same current at similar temperature rise. Copper, although heavier and costlier, offers compact dimensions and better thermal performance.

Find out more about High Impedance Busbar Protection Explained with Example Calculations

Step by Step Practical Approach

Engineers often follow a structured workflow when conducting busbar heating calculation for real installations.

- Determine load current based on system study

- Select tentative material and dimensions

- Calculate conductor resistance for operating temperature

- Compute I²R losses

- Apply enclosure or grouping correction factors

- Estimate temperature rise from empirical charts

- Compare with allowable limits

- Adjust dimensions if required

This method ensures thermal safety without excessive oversizing. Many professionals also verify results using specialized electrical design software, especially for complex arrangements.

Typical Current Density Guidance

Although detailed analysis provides the most accurate results, approximate current density values help during initial planning.

| Installation Type | Copper Current Density | Aluminum Current Density |

|---|---|---|

| Open Air | 1.5 to 2 A/mm² | 1 to 1.4 A/mm² |

| Enclosed Panel | 1 to 1.4 A/mm² | 0.8 to 1.1 A/mm² |

| High Reliability Systems | Lower end values | Lower end values |

These ranges act only as starting references. Final sizing still requires complete busbar heating calculation considering environmental factors and duty cycle.

Find out more about Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

Standards and Compliance Considerations

Regulatory frameworks influence temperature limits and testing procedures. Designers often reference international standards when documenting busbar heating calculation results.

Relevant guidance includes:

- IEC switchgear temperature rise requirements

- IEEE recommendations for conductor design

- Manufacturer test data and certification

- Project specification limits

Compliance ensures the installation passes inspection and operates safely across expected service life. Documentation of calculation steps also supports engineering audits and quality control.

Find out more about iec 61439 busbar clearance

Design Practices That Reduce Heating

Beyond mathematical evaluation, practical layout decisions can significantly reduce temperature buildup.

- Increase spacing between phases to enhance airflow

- Use ventilated enclosures or forced cooling

- Apply plating to reduce oxidation

- Avoid sharp bends that increase resistance

- Maintain clean connections with proper torque

These measures complement busbar heating calculation by addressing real world conditions that pure formulas cannot capture.

Example Overview of Calculation Logic

Consider a simplified scenario where an engineer evaluates a distribution panel feeder. After estimating current, the designer calculates conductor resistance and resulting losses. Using correction factors for enclosure temperature, predicted rise is compared with permissible limits. If the temperature exceeds the threshold, the cross section is increased or ventilation improved.

Get complete information about iec standard for busbar sizing

This practical loop demonstrates how busbar heating calculation integrates into overall electrical design rather than existing as a standalone academic exercise.

Conclusion

Thermal performance remains one of the most critical aspects of power distribution reliability. A well executed busbar heating calculation ensures conductors operate within safe limits, supports regulatory compliance, and prevents costly failures. By understanding electrical losses, material properties, and environmental conditions, engineers can design efficient busbar systems that balance performance and cost.

The process involves evaluating resistance losses, estimating heat dissipation, and validating temperature rise through recognized methods. Tables, empirical data, and practical experience all contribute to accurate results. When applied consistently from early planning through final verification, busbar heating calculation becomes a valuable tool that strengthens electrical infrastructure and extends equipment life. Read in detail about iec 61439 busbar calculation

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#busbarheatingcalculation, #busbardesign, #electricalengineering, #powersystems, #switchgear, #currentcarryingcapacity, #thermalanalysis, #busbarcalculation, #electricaldesign, #engineeringtools